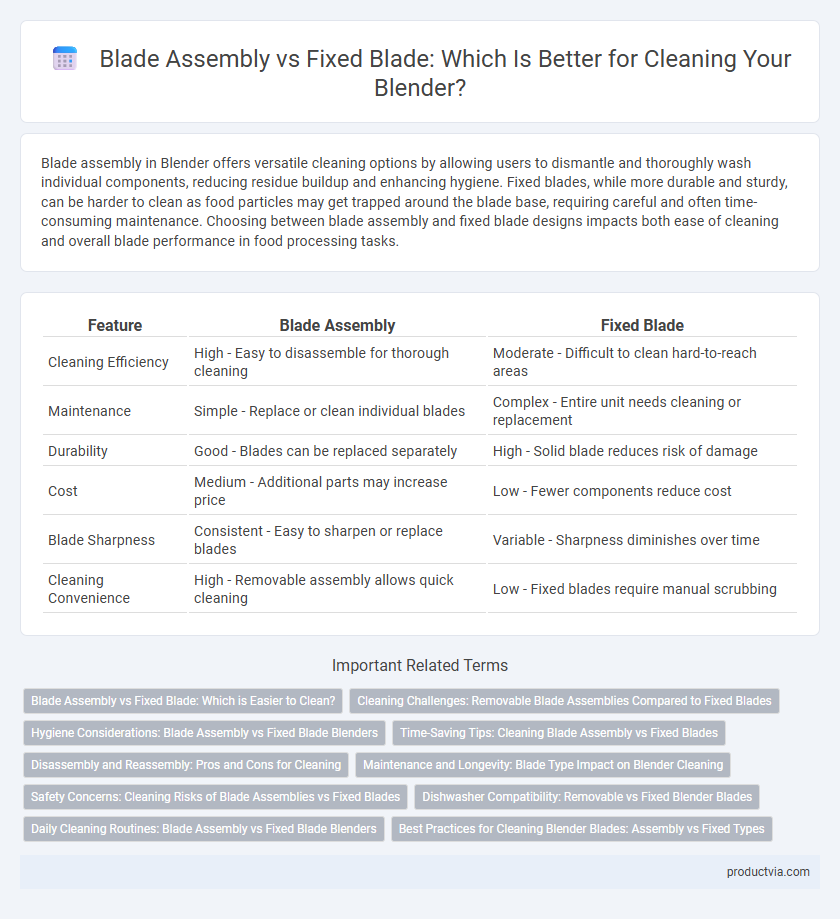

Blade assembly in Blender offers versatile cleaning options by allowing users to dismantle and thoroughly wash individual components, reducing residue buildup and enhancing hygiene. Fixed blades, while more durable and sturdy, can be harder to clean as food particles may get trapped around the blade base, requiring careful and often time-consuming maintenance. Choosing between blade assembly and fixed blade designs impacts both ease of cleaning and overall blade performance in food processing tasks.

Table of Comparison

| Feature | Blade Assembly | Fixed Blade |

|---|---|---|

| Cleaning Efficiency | High - Easy to disassemble for thorough cleaning | Moderate - Difficult to clean hard-to-reach areas |

| Maintenance | Simple - Replace or clean individual blades | Complex - Entire unit needs cleaning or replacement |

| Durability | Good - Blades can be replaced separately | High - Solid blade reduces risk of damage |

| Cost | Medium - Additional parts may increase price | Low - Fewer components reduce cost |

| Blade Sharpness | Consistent - Easy to sharpen or replace blades | Variable - Sharpness diminishes over time |

| Cleaning Convenience | High - Removable assembly allows quick cleaning | Low - Fixed blades require manual scrubbing |

Blade Assembly vs Fixed Blade: Which is Easier to Clean?

Blade assemblies in Blender models offer modular components that can be easily detached for thorough cleaning, reducing the risk of residue buildup and bacterial growth. Fixed blades, integrated directly into the blender base or jar, often present cleaning challenges due to limited access around the blade edges and hidden crevices. The detachable nature of blade assemblies makes them a more user-friendly choice for maintaining hygiene and ensuring long-term performance in blender maintenance.

Cleaning Challenges: Removable Blade Assemblies Compared to Fixed Blades

Removable blade assemblies in Blender present cleaning challenges such as food residue trapping in blade joints and increased disassembly time, leading to potential hygiene issues. Fixed blades offer a seamless design that minimizes crevices where food particles can accumulate, enabling easier and more thorough cleaning. However, fixed blades require more effort to clean around the base, creating a trade-off between convenience and maintenance.

Hygiene Considerations: Blade Assembly vs Fixed Blade Blenders

Blade assembly blenders offer easier cleaning due to detachable parts, reducing bacterial buildup and ensuring better hygiene compared to fixed blade blenders whose integrated design can trap food particles. Fixed blade blenders often require more thorough cleaning methods to prevent contamination, posing a higher risk of mold and bacterial growth in hard-to-reach areas. Opting for a blade assembly blender enhances sanitation and maintains food safety through convenient disassembly and comprehensive cleaning.

Time-Saving Tips: Cleaning Blade Assembly vs Fixed Blades

Blade assembly systems in Blender models can significantly reduce cleaning time due to their removable and dishwasher-safe components, enabling quick disassembly and thorough rinse without requiring extensive scrubbing. Fixed blades often trap food particles under the blade base, demanding more effort and time for manual cleaning and increasing the risk of residue buildup. Choosing blade assemblies designed for easy detachment optimizes maintenance efficiency and minimizes downtime between uses.

Disassembly and Reassembly: Pros and Cons for Cleaning

Blade assembly in Blender designs allows easy disassembly, enabling thorough cleaning of individual components and reducing buildup of food residue. Fixed blade models offer simpler maintenance with fewer parts, but cleaning can be less effective due to limited access to the blade and gasket areas. Users prioritizing hygiene and deep cleaning often prefer blade assemblies for their modularity, despite the slightly longer reassembly time.

Maintenance and Longevity: Blade Type Impact on Blender Cleaning

Blade assembly in blenders allows for easier disassembly, facilitating thorough cleaning and reducing food residue buildup that can cause bacterial growth. Fixed blades, integrated into the pitcher, often trap food particles around seals and gaskets, making deep cleaning challenging and increasing wear over time. Regular maintenance of blade assemblies extends blender longevity by preventing corrosion and preserving sharpness, while fixed blades may require more frequent replacement due to difficult cleaning and resulting damage.

Safety Concerns: Cleaning Risks of Blade Assemblies vs Fixed Blades

Blade assemblies in Blender designs pose higher safety risks during cleaning due to multiple detachable parts with sharp edges that can cause cuts or injuries if removed or handled improperly. Fixed blades offer enhanced safety by remaining securely attached, reducing exposure to sharp components and minimizing accidental contact during cleaning processes. Proper tool design and clear manufacturer guidelines are crucial to mitigate cleaning hazards associated with blade assemblies in Blender appliances.

Dishwasher Compatibility: Removable vs Fixed Blender Blades

Removable blades in blender assemblies offer superior dishwasher compatibility due to their easy detachment, allowing thorough cleaning and reducing the risk of water damage to the motor base. Fixed blades, integrated into the blender jar, are harder to clean and less dishwasher-friendly, often requiring manual scrubbing to remove food residues effectively. Choosing blenders with blade assemblies designed for dishwasher use ensures better hygiene and maintenance convenience.

Daily Cleaning Routines: Blade Assembly vs Fixed Blade Blenders

Blade assembly blenders offer easier disassembly, enabling thorough cleaning of all components and reducing residue buildup during daily routines. Fixed blade blenders require more effort to clean around the blades, increasing the likelihood of trapped food particles and bacteria. Choosing blade assembly models enhances hygiene and maintenance efficiency for everyday use.

Best Practices for Cleaning Blender Blades: Assembly vs Fixed Types

Cleaning blender blades requires distinct approaches based on blade type: assembled blades with removable parts allow thorough disassembly for deep cleaning, preventing residue buildup and ensuring hygiene. Fixed blade units demand careful scrubbing with a brush and mild detergent to reach crevices while avoiding water damage to internal components. Regular maintenance following these best practices enhances blade longevity and maintains optimal blending performance.

Blade assembly vs fixed blade for cleaning Infographic

productvia.com

productvia.com