Blade design plays a crucial role in efficiently crushing ice by maximizing surface contact and minimizing resistance, allowing for smoother and more effective crushing. Motor power determines the blender's ability to maintain high speeds and torque under load, which is essential for breaking down hard ice cubes quickly. A balance between sharp, angled blades and a robust motor ensures optimal performance in ice crushing tasks without overloading the blender.

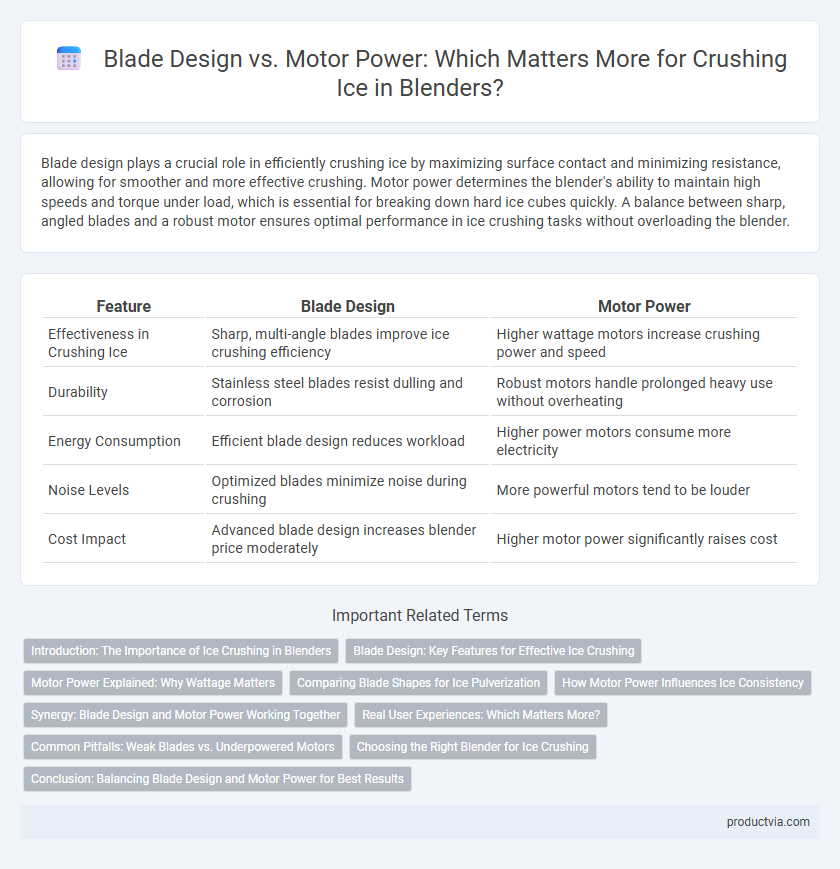

Table of Comparison

| Feature | Blade Design | Motor Power |

|---|---|---|

| Effectiveness in Crushing Ice | Sharp, multi-angle blades improve ice crushing efficiency | Higher wattage motors increase crushing power and speed |

| Durability | Stainless steel blades resist dulling and corrosion | Robust motors handle prolonged heavy use without overheating |

| Energy Consumption | Efficient blade design reduces workload | Higher power motors consume more electricity |

| Noise Levels | Optimized blades minimize noise during crushing | More powerful motors tend to be louder |

| Cost Impact | Advanced blade design increases blender price moderately | Higher motor power significantly raises cost |

Introduction: The Importance of Ice Crushing in Blenders

Efficient ice crushing in blenders relies heavily on the blade design and motor power working in harmony to deliver optimal performance. High-quality stainless steel blades with specific angles and sharpness reduce strain on a motor rated above 600 watts, ensuring consistent ice pulverization. Proper balance between blade geometry and wattage prevents overheating and prolongs blender lifespan while producing smooth, ice-free textures.

Blade Design: Key Features for Effective Ice Crushing

Blade design for ice crushing in Blender models features sharp, angled stainless steel blades that maximize surface contact and pressure distribution for efficient ice pulverization. Multi-tiered blade systems enhance the ability to chip and crush ice by creating layered cutting points that prevent clogging and promote continuous ice flow. Optimal blade height and spacing are engineered to balance torque demands with motor power, reducing strain while delivering consistent ice crushing performance.

Motor Power Explained: Why Wattage Matters

Motor power in watts is crucial for ice crushers in Blender, as higher wattage motors deliver greater torque needed to crush hard ice efficiently. Blades designed with sharp, durable materials work best when paired with motors above 500 watts, ensuring consistent ice crushing without straining the motor. Optimal motor power enhances blade performance by maintaining speed and force, preventing overheating and prolonging appliance lifespan.

Comparing Blade Shapes for Ice Pulverization

Flat and serrated blade designs influence ice pulverization efficiency by altering surface contact and cutting mechanics. Curved blades generate more torque, enhancing motor power utilization for crushing dense ice compared to straight blades. Optimal blade shape selection maximizes ice crushing performance by balancing motor load and cutting effectiveness.

How Motor Power Influences Ice Consistency

Motor power directly impacts the blade's ability to crush ice efficiently, with higher wattage motors generating greater torque for smoother, finer ice consistency. Blades designed with sharp, angled edges require substantial motor power to maintain optimal rotation speed and prevent stalling when encountering dense ice chunks. Consistent motor torque ensures uniform blade contact and reduces uneven ice fragmentation, producing a reliable crushed ice texture for smoothies or cocktails.

Synergy: Blade Design and Motor Power Working Together

Blade design and motor power in Blender models create a synergy that optimizes ice crushing efficiency. Sharp, angled blades reduce resistance and maximize surface impact while powerful motors generate the torque needed to drive blades through dense ice. The precise balance between blade geometry and motor RPM ensures consistent crushing performance and prevents motor strain.

Real User Experiences: Which Matters More?

Real user experiences reveal that blade design in Blender significantly impacts crushing ice efficiency, often surpassing the influence of motor power alone. Sharp, angled, and strategically placed blades create superior ice fragmentation even with moderate motor strength, enhancing blending performance and reducing strain on the motor. Users report that blenders with optimized blade geometry consistently deliver smoother ice crushing compared to models boasting higher wattage but less effective blade structures.

Common Pitfalls: Weak Blades vs. Underpowered Motors

Weak blades in Blender ice crushers often fail to effectively break down ice, causing uneven crushing and strain on the motor. Underpowered motors struggle to generate the necessary torque, leading to inefficient blade rotation and frequent motor burnout. Optimal ice crushing requires a balance between sharp, durable blades and a motor with sufficient horsepower, typically above 500 watts, to ensure consistent performance and longevity.

Choosing the Right Blender for Ice Crushing

A blender's blade design significantly impacts its ability to crush ice effectively, with stainless steel blades featuring serrated edges providing superior durability and sharper cutting angles for breaking down ice chunks. Motor power of at least 600 watts is crucial to maintain blade speed and torque, ensuring consistent crushing performance without motor strain. Selecting a blender that balances robust blade construction with high wattage motor power optimizes ice crushing efficiency and prevents frequent blade dulling or motor overheating.

Conclusion: Balancing Blade Design and Motor Power for Best Results

Optimal ice crushing performance in Blender depends on carefully balancing blade design and motor power. Sharp, sturdy blades made from high-quality stainless steel enhance cutting efficiency, while a motor with sufficient wattage (typically above 600 watts) ensures consistent crushing power. Achieving synergy between these factors minimizes strain on the motor and delivers finely crushed ice for smooth, ice-cold beverages.

Blade design vs motor power for crushing ice Infographic

productvia.com

productvia.com