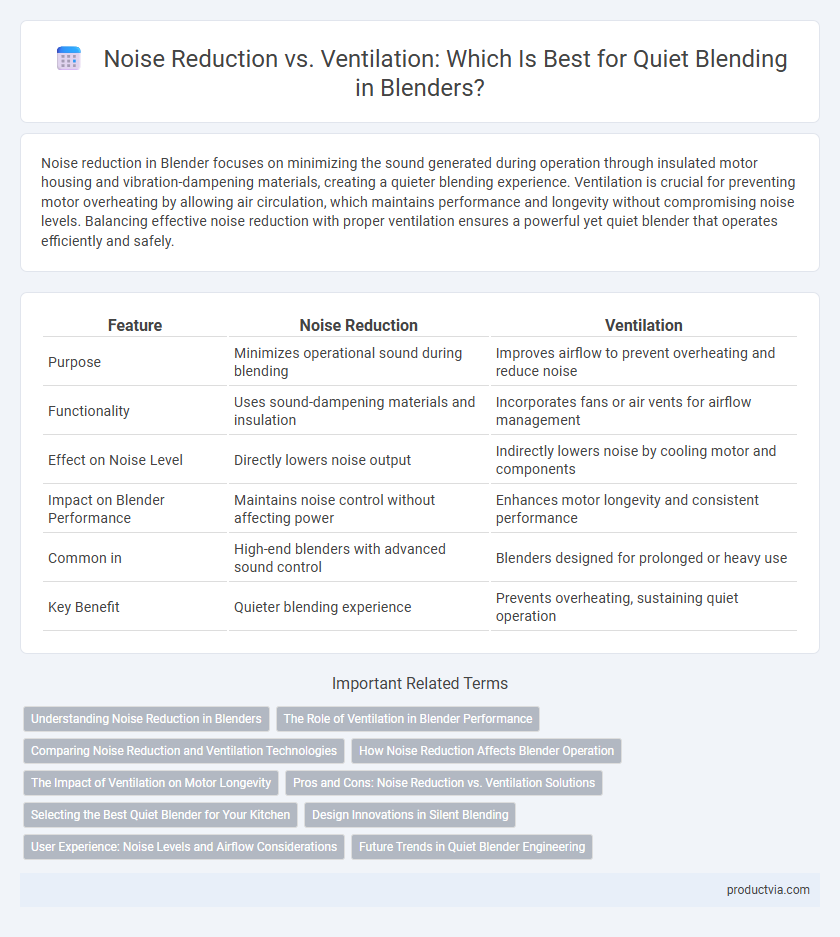

Noise reduction in Blender focuses on minimizing the sound generated during operation through insulated motor housing and vibration-dampening materials, creating a quieter blending experience. Ventilation is crucial for preventing motor overheating by allowing air circulation, which maintains performance and longevity without compromising noise levels. Balancing effective noise reduction with proper ventilation ensures a powerful yet quiet blender that operates efficiently and safely.

Table of Comparison

| Feature | Noise Reduction | Ventilation |

|---|---|---|

| Purpose | Minimizes operational sound during blending | Improves airflow to prevent overheating and reduce noise |

| Functionality | Uses sound-dampening materials and insulation | Incorporates fans or air vents for airflow management |

| Effect on Noise Level | Directly lowers noise output | Indirectly lowers noise by cooling motor and components |

| Impact on Blender Performance | Maintains noise control without affecting power | Enhances motor longevity and consistent performance |

| Common in | High-end blenders with advanced sound control | Blenders designed for prolonged or heavy use |

| Key Benefit | Quieter blending experience | Prevents overheating, sustaining quiet operation |

Understanding Noise Reduction in Blenders

Noise reduction in blenders relies on advanced insulation materials and specially designed motor housings to minimize sound output during operation. Enhanced ventilation systems help maintain motor temperature without compromising noise control, balancing airflow and acoustic dampening for quieter blending. Understanding these technologies assists users in selecting blenders that deliver efficient performance while ensuring minimal noise disturbance in the kitchen environment.

The Role of Ventilation in Blender Performance

Proper ventilation in blender design significantly reduces operational noise by preventing motor overheating and maintaining consistent performance. Effective airflow systems dissipate heat, allowing the motor to run smoothly at optimal speeds without strain-induced noise spikes. Consequently, ventilation plays a crucial role in achieving quiet blending alongside traditional noise reduction techniques.

Comparing Noise Reduction and Ventilation Technologies

Effective noise reduction in Blender appliances relies on advanced sound-dampening materials and motor insulation, minimizing disruptive noise during operation. Ventilation technologies enhance quiet blending by improving airflow and cooling, preventing overheating which can increase motor noise levels. Comparing these methods reveals that noise reduction focuses on blocking and absorbing sound, while ventilation targets performance stability that indirectly lowers noise emissions.

How Noise Reduction Affects Blender Operation

Noise reduction technology in blenders minimizes sound levels by insulating the motor and optimizing blade design, which enhances user comfort without compromising performance. Ventilation systems are engineered to dissipate heat effectively, preventing motor overheating and maintaining consistent blending power during extended use. Proper integration of noise reduction and ventilation ensures quiet operation while preserving blender efficiency and longevity.

The Impact of Ventilation on Motor Longevity

Effective ventilation in blenders plays a crucial role in noise reduction by preventing motor overheating and ensuring continuous airflow. Proper airflow minimizes thermal stress on motor components, extending motor longevity and maintaining quiet blending performance. Optimizing cooling systems reduces the risk of motor burnout while enabling consistent, low-noise operation during high-speed blending tasks.

Pros and Cons: Noise Reduction vs. Ventilation Solutions

Noise reduction techniques in Blender focus on minimizing sound through insulation and sound-dampening materials, effectively lowering noise levels but potentially causing heat buildup and reduced airflow. Ventilation solutions promote airflow to prevent overheating, maintaining blender performance and longevity but can increase noise levels due to less sound insulation. Balancing noise reduction with adequate ventilation ensures quiet blending without compromising motor cooling and durability.

Selecting the Best Quiet Blender for Your Kitchen

Selecting the best quiet blender for your kitchen involves balancing noise reduction technology with efficient ventilation systems that prevent overheating while minimizing sound output. Look for blenders featuring sound-dampening materials and designs that optimize airflow through strategically placed vents, ensuring smooth motor operation without excessive noise. Prioritize models with insulated motor housings and variable speed controls to achieve powerful blending performance quietly and reliably.

Design Innovations in Silent Blending

Design innovations in silent blending prioritize advanced noise reduction techniques integrated into blender ventilation systems to minimize sound output without compromising airflow efficiency. Specialized airflow channels and sound-dampening materials reduce motor noise while maintaining optimal cooling, ensuring durable performance and quieter operation. These innovations enhance user experience by combining effective noise control with reliable ventilation for extended blender lifespan.

User Experience: Noise Levels and Airflow Considerations

Blender noise reduction technology enhances user experience by minimizing operational sound while maintaining efficient airflow to prevent motor overheating. Effective ventilation channels are essential to balance quiet blending with optimal cooling performance, ensuring longevity and safety of the appliance. Low-noise motor design paired with strategic airflow management reduces acoustic discomfort and improves overall kitchen environment during food preparation.

Future Trends in Quiet Blender Engineering

Future trends in quiet blender engineering emphasize advanced noise reduction technologies combined with innovative ventilation designs to minimize sound without compromising airflow and cooling efficiency. Emerging materials such as acoustic foams and vibration-dampening composites are integrated to absorb blender motor noise while maintaining optimal ventilation channels inspired by aerodynamics. These developments enhance user experience by delivering powerful blending performance with unprecedented quiet operation, setting new standards in kitchen appliance innovation.

Noise reduction vs ventilation for quiet blending Infographic

productvia.com

productvia.com