Belt-driven motors in bread makers offer quieter operation and smoother performance, reducing wear on internal components for long-term durability. Direct drive motors provide more power and precise control over kneading speed, ensuring consistent dough texture and faster baking cycles. Choosing between them depends on prioritizing noise reduction and maintenance ease or enhanced motor efficiency and baking precision.

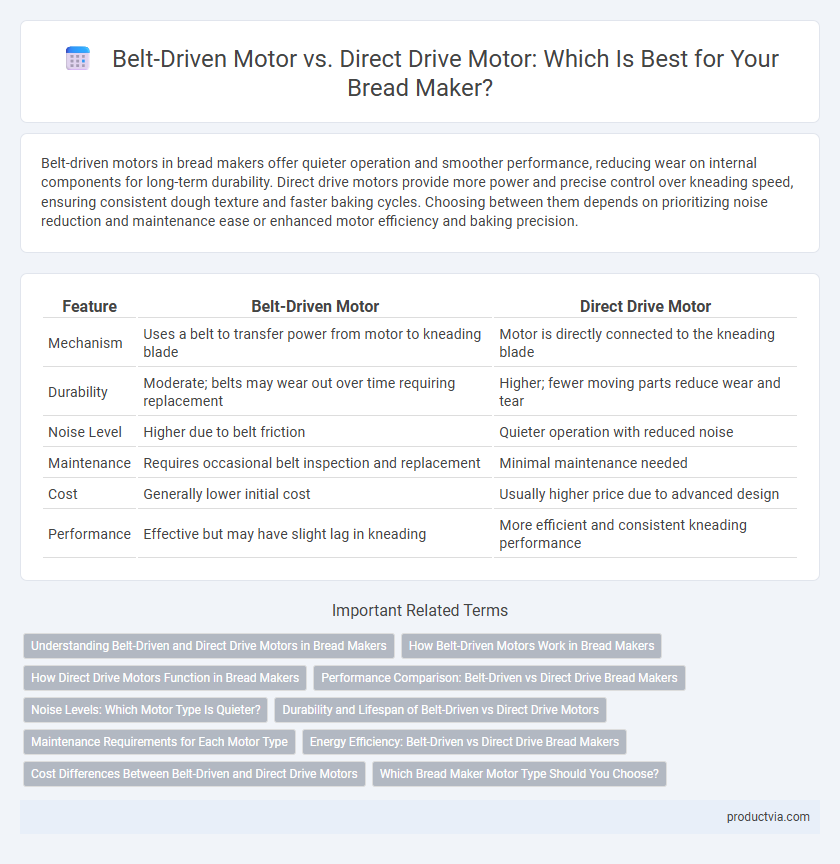

Table of Comparison

| Feature | Belt-Driven Motor | Direct Drive Motor |

|---|---|---|

| Mechanism | Uses a belt to transfer power from motor to kneading blade | Motor is directly connected to the kneading blade |

| Durability | Moderate; belts may wear out over time requiring replacement | Higher; fewer moving parts reduce wear and tear |

| Noise Level | Higher due to belt friction | Quieter operation with reduced noise |

| Maintenance | Requires occasional belt inspection and replacement | Minimal maintenance needed |

| Cost | Generally lower initial cost | Usually higher price due to advanced design |

| Performance | Effective but may have slight lag in kneading | More efficient and consistent kneading performance |

Understanding Belt-Driven and Direct Drive Motors in Bread Makers

Belt-driven motors in bread makers operate by using a belt to connect the motor to the kneading paddle, offering quieter performance and easier maintenance, while direct drive motors attach the paddle directly to the motor shaft, providing more efficient power transfer and greater durability. Belt-driven systems tend to reduce motor noise and vibration, making them ideal for home use, whereas direct drive motors enhance control precision and typically result in longer motor lifespan due to fewer moving components. Choosing between these motor types depends on prioritizing quieter operation or maximizing mechanical efficiency and longevity in bread making.

How Belt-Driven Motors Work in Bread Makers

Belt-driven motors in bread makers operate by using a rubber belt to transfer power from the motor to the kneading blade, ensuring smooth and quiet operation. This design reduces vibration and impact noise compared to direct drive motors, contributing to a more stable baking process. The belt mechanism also allows for easier motor replacement and maintenance, extending the appliance's lifespan.

How Direct Drive Motors Function in Bread Makers

Direct drive motors in bread makers operate by connecting the motor shaft directly to the kneading paddle, eliminating the need for a belt and reducing mechanical loss. This direct connection allows for more efficient energy transfer, resulting in quieter operation and enhanced durability. The precision control of direct drive motors contributes to consistent kneading performance, improving the quality of the dough.

Performance Comparison: Belt-Driven vs Direct Drive Bread Makers

Belt-driven bread makers typically offer quieter operation and easier maintenance due to the buffer created by the belt, while direct drive motors provide more efficient power transfer, resulting in faster and more precise kneading performance. Direct drive systems tend to have fewer mechanical parts, reducing the risk of belt wear and improving the machine's durability and consistency in dough texture. Performance-wise, direct drive bread makers often excel in handling dense or large batches, whereas belt-driven models may produce less vibration and noise during the kneading cycle.

Noise Levels: Which Motor Type Is Quieter?

Belt-driven motors in bread makers typically generate less noise due to the belt absorbing vibrations between the motor and the kneading blade, resulting in quieter operation. In contrast, direct drive motors connect the motor directly to the blade, which can produce louder sounds because vibrations transfer without any dampening. Consumers seeking a quieter bread-making experience often prefer belt-driven motor models for their reduced noise levels.

Durability and Lifespan of Belt-Driven vs Direct Drive Motors

Belt-driven motors in bread makers typically offer longer durability due to reduced stress on the motor components, as the belt absorbs shocks and vibrations, extending the lifespan of the machine. Direct drive motors connect the motor shaft directly to the bread-making paddle, resulting in higher efficiency but increased wear and shorter lifespan from continuous strain. Choosing a belt-driven motor often means enhanced durability and longer maintenance intervals compared to direct drive alternatives.

Maintenance Requirements for Each Motor Type

Belt-driven motors in bread makers require periodic belt inspections and replacements due to wear and tear, increasing overall maintenance efforts. Direct drive motors feature fewer moving parts, resulting in lower maintenance needs and higher durability over time. Choosing a direct drive motor often reduces long-term upkeep costs and improves reliability in bread making appliances.

Energy Efficiency: Belt-Driven vs Direct Drive Bread Makers

Direct drive motors in bread makers generally offer higher energy efficiency by transmitting power directly to the kneading paddle, minimizing energy loss commonly found in belt-driven systems. Belt-driven motor bread makers may consume more power due to friction and slippage in the belt mechanism, reducing overall energy performance. Choosing a direct drive bread maker model can result in lower electricity consumption and improved durability over time.

Cost Differences Between Belt-Driven and Direct Drive Motors

Belt-driven motors in bread makers are generally more affordable due to simpler construction and widespread availability of parts, making them a cost-effective choice for budget-conscious consumers. Direct drive motors, featuring a more complex design with the motor connected directly to the kneading mechanism, typically come at a higher manufacturing cost, reflecting in the retail price of the bread maker. Cost differences also impact maintenance expenses, as belt-driven models may require periodic belt replacements, while direct drive motors often offer longer durability but at a premium initial investment.

Which Bread Maker Motor Type Should You Choose?

Choosing between a belt-driven motor and a direct drive motor for a bread maker depends on durability and noise levels. Belt-driven motors offer quieter operation and easier maintenance, making them ideal for frequent use, while direct drive motors provide higher power and longer lifespan with less vibration. For the best performance in a home bread maker, direct drive motors generally ensure consistent kneading and faster baking cycles.

Belt-driven motor vs Direct drive motor for bread maker Infographic

productvia.com

productvia.com