The Bowl Chopper offers precise, consistent mincing ideal for fine textures, while the Cleaver Chopper excels in handling tougher cuts and larger meat portions with its robust blade design. For minced meat, the Bowl Chopper delivers smoother results that enhance flavor absorption and cooking uniformity. Choosing between these choppers depends on the desired texture and the volume of meat processing.

Table of Comparison

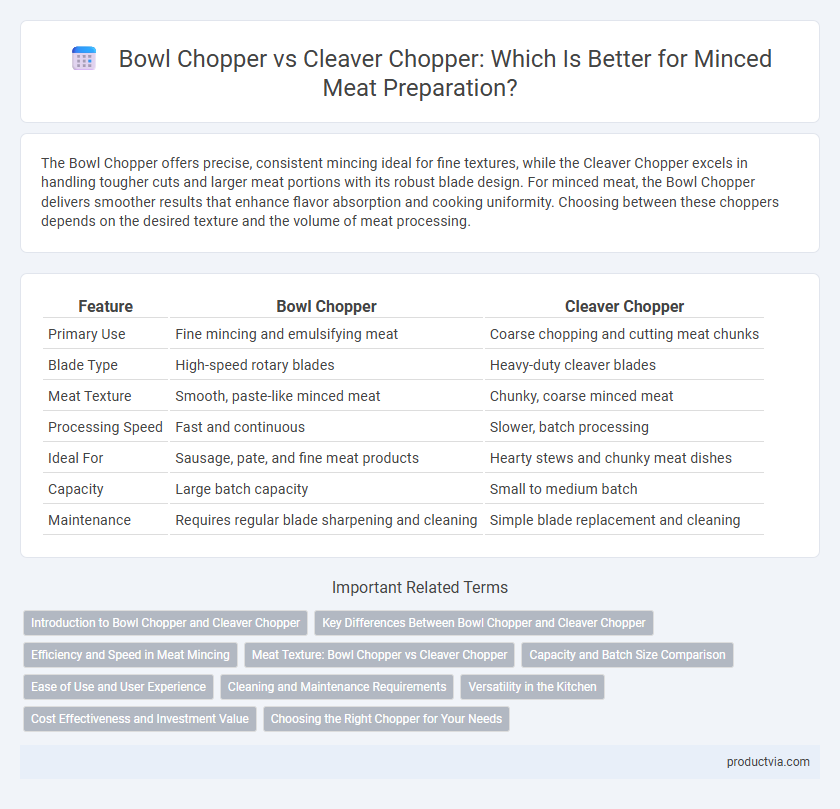

| Feature | Bowl Chopper | Cleaver Chopper |

|---|---|---|

| Primary Use | Fine mincing and emulsifying meat | Coarse chopping and cutting meat chunks |

| Blade Type | High-speed rotary blades | Heavy-duty cleaver blades |

| Meat Texture | Smooth, paste-like minced meat | Chunky, coarse minced meat |

| Processing Speed | Fast and continuous | Slower, batch processing |

| Ideal For | Sausage, pate, and fine meat products | Hearty stews and chunky meat dishes |

| Capacity | Large batch capacity | Small to medium batch |

| Maintenance | Requires regular blade sharpening and cleaning | Simple blade replacement and cleaning |

Introduction to Bowl Chopper and Cleaver Chopper

Bowl choppers utilize a rotating bowl and multiple sharp blades to finely mince meat with precision and consistency, making them ideal for producing smooth textures in sausages and processed meats. Cleaver choppers employ larger, slower-moving blades that mimic manual chopping, preserving meat fibers for coarser textures preferred in specialty products. Both machines serve distinct purposes in meat processing, with bowl choppers excelling in fine mincing and cleaver choppers maintaining coarse, chunkier meat structures.

Key Differences Between Bowl Chopper and Cleaver Chopper

Bowl choppers use rotating blades inside a bowl to finely mince meat with consistent texture, ideal for sausages and emulsified products, while cleaver choppers feature straight, oscillating knives that produce coarser cuts and preserve more meat structure. The bowl chopper's design allows for high-speed chopping and better temperature control, preventing fat smearing and ensuring uniform particle size. Cleaver choppers excel in applications requiring larger chunks of meat or less emulsification, offering greater versatility for specific minced meat products.

Efficiency and Speed in Meat Mincing

Bowl choppers excel in efficiency and speed for minced meat due to their high-capacity rotating bowl and rapid, continuous mixing and cutting action, enabling consistent texture and quicker processing times. Cleaver choppers, while effective for coarser cuts, operate with slower batch processing and require more manual intervention, reducing overall throughput. The advanced motor-driven mechanism in bowl choppers optimizes uniform mincing at industrial scales, surpassing cleaver choppers in rapid meat preparation.

Meat Texture: Bowl Chopper vs Cleaver Chopper

Bowl choppers produce a finer, more uniform minced meat texture due to their high-speed rotating blades and bowl design, efficiently cutting and mixing the meat. Cleaver choppers deliver a coarser, chunkier texture as their larger, heavier blades perform a chopping action rather than a pure cutting one. For achieving smooth emulsions or sausage fillings, bowl choppers are preferred, whereas cleaver choppers are better suited for meals requiring a rustic or meatier bite.

Capacity and Batch Size Comparison

Bowl choppers typically offer larger capacity and handle bigger batch sizes, making them ideal for high-volume minced meat production in industrial settings. Cleaver choppers, with smaller bowl sizes, suit moderate batch processing, providing precise cutting for specialized or smaller-scale applications. Choosing between them depends on production scale and required output volume.

Ease of Use and User Experience

Bowl choppers offer superior ease of use with their integrated bowl design that keeps minced meat contained, minimizing mess and allowing for efficient processing. Cleaver choppers require more manual effort and skill, often causing uneven cuts and increased cleanup time, which can hinder the user experience. The ergonomic handle and consistent chopping action of bowl choppers result in less fatigue and more precise minced meat texture, enhancing overall usability.

Cleaning and Maintenance Requirements

Bowl choppers feature removable blades and a detachable bowl, allowing thorough cleaning and easier maintenance compared to cleaver choppers. Cleaver choppers have fixed, heavy blades that require more effort to disassemble and clean, increasing downtime and risk of residue buildup. Frequent cleaning is critical for both to maintain hygiene standards and prevent cross-contamination in minced meat processing.

Versatility in the Kitchen

Bowl choppers excel in versatility with their ability to finely mince, chop, and blend a variety of ingredients for diverse recipes, including sausages and pates. Cleaver choppers offer precision cutting and are ideal for tougher meats and larger chunks, making them perfect for coarse mincing and creating uniform textures. Choosing between a bowl chopper and a cleaver chopper depends on the desired texture and the range of minced meat preparations in the kitchen.

Cost Effectiveness and Investment Value

Bowl choppers offer higher cost effectiveness for minced meat production due to their efficient mixing and fine cutting capabilities, reducing preparation time and labor costs. Cleaver choppers, while initially cheaper, tend to have higher maintenance expenses and lower precision, impacting long-term investment value. Investing in a bowl chopper yields better durability and consistent product quality, maximizing return over time.

Choosing the Right Chopper for Your Needs

Bowl choppers provide consistent, fine mincing ideal for smooth-textured minced meat, utilizing high-speed rotating knives in a stationary bowl to achieve uniform particle size. Cleaver choppers excel in handling tougher cuts and producing coarser textures by delivering powerful chopping forces with large blades, suitable for chunkier meat preparations. Selecting the right chopper depends on the desired meat texture and production scale, with bowl choppers preferred for fine, emulsified products and cleaver choppers suited for robust, coarse mince.

Bowl Chopper vs Cleaver Chopper for minced meat Infographic

productvia.com

productvia.com