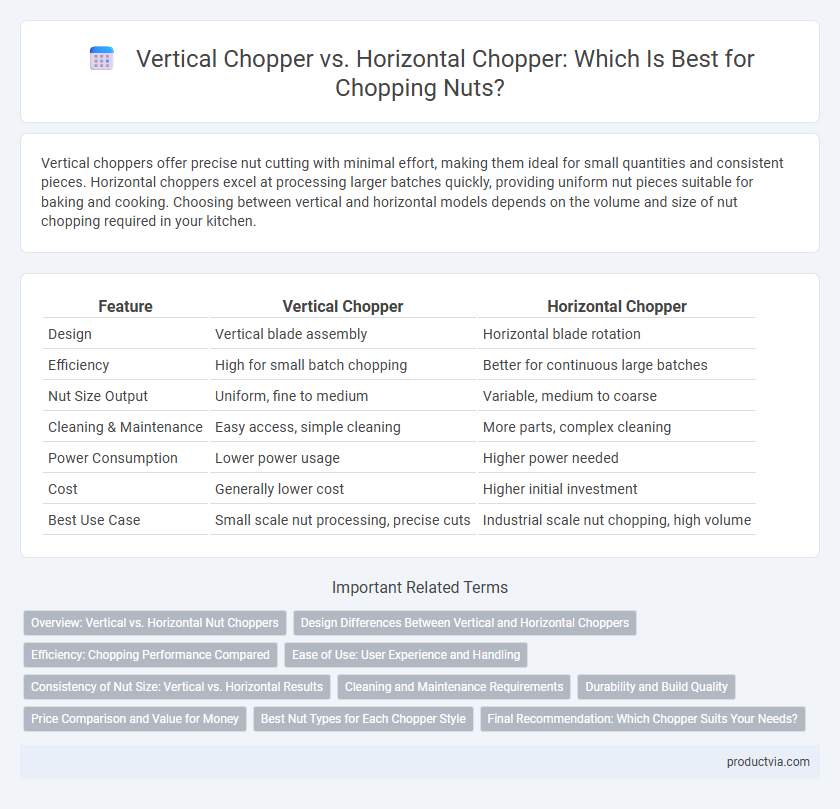

Vertical choppers offer precise nut cutting with minimal effort, making them ideal for small quantities and consistent pieces. Horizontal choppers excel at processing larger batches quickly, providing uniform nut pieces suitable for baking and cooking. Choosing between vertical and horizontal models depends on the volume and size of nut chopping required in your kitchen.

Table of Comparison

| Feature | Vertical Chopper | Horizontal Chopper |

|---|---|---|

| Design | Vertical blade assembly | Horizontal blade rotation |

| Efficiency | High for small batch chopping | Better for continuous large batches |

| Nut Size Output | Uniform, fine to medium | Variable, medium to coarse |

| Cleaning & Maintenance | Easy access, simple cleaning | More parts, complex cleaning |

| Power Consumption | Lower power usage | Higher power needed |

| Cost | Generally lower cost | Higher initial investment |

| Best Use Case | Small scale nut processing, precise cuts | Industrial scale nut chopping, high volume |

Overview: Vertical vs. Horizontal Nut Choppers

Vertical nut choppers feature a blade mounted on a vertical axis, providing precision cuts ideal for consistent nut sizes and preserving texture during processing. Horizontal nut choppers use a horizontally oriented blade that excels at handling larger batches quickly but may result in less uniform pieces due to the slicing action. Choosing between vertical and horizontal nut choppers depends on the desired nut size uniformity and processing volume requirements.

Design Differences Between Vertical and Horizontal Choppers

Vertical choppers feature a blade assembly oriented perpendicular to the base, allowing nuts to be chopped through a downward slicing motion that promotes uniform size and reduces clumping. Horizontal choppers use a blade positioned parallel to the base, creating a sweeping action ideal for larger batches but sometimes resulting in less consistent nut pieces. Design differences affect the efficiency and texture of nut chopping, with vertical models often preferred for precision and horizontal choppers favored for volume processing.

Efficiency: Chopping Performance Compared

Vertical choppers offer higher efficiency for nut processing due to their gravity-assisted chopping action, resulting in uniform cuts and reduced motor strain. Horizontal choppers provide consistent performance but may require more motor power to achieve similar chopping precision. For optimal nut chopping, vertical choppers often deliver faster throughput and improved energy efficiency compared to horizontal models.

Ease of Use: User Experience and Handling

Vertical choppers offer superior ease of use for nuts with ergonomic designs that allow better control and precision during chopping. Horizontal choppers tend to require more effort and careful handling to achieve consistent cuts, potentially leading to user fatigue. The vertical orientation supports more comfortable gripping and efficient chopping motions, enhancing overall user experience.

Consistency of Nut Size: Vertical vs. Horizontal Results

Vertical choppers produce more uniform nut pieces due to their blade orientation, which allows for consistent downward slicing through the nuts. Horizontal choppers often yield a less even nut size because their blades spin parallel to the cutting surface, leading to more irregular cuts and sometimes uneven chopping. For tasks requiring precise and consistent nut size, vertical choppers typically outperform horizontal models in maintaining uniformity.

Cleaning and Maintenance Requirements

Vertical choppers for nuts typically offer easier cleaning due to their upright design, allowing better access to blades and internal components. Horizontal choppers may require more disassembly for thorough cleaning, as their horizontal orientation can trap nut particles within hard-to-reach areas. Maintenance for vertical choppers is generally simpler and quicker, reducing downtime and enhancing operational efficiency.

Durability and Build Quality

Vertical choppers for nuts typically feature robust stainless steel blades and reinforced motor housings, enhancing their durability and resistance to wear during heavy use. Horizontal choppers often have a more compact design but may use lighter materials, potentially compromising long-term build quality under frequent processing of hard nuts. Choosing a vertical chopper ensures better structural integrity and sustained performance, especially in commercial or high-volume settings.

Price Comparison and Value for Money

Vertical choppers typically have a higher price point due to their more complex design and enhanced efficiency in chopping nuts evenly. Horizontal choppers, while more affordable, may sacrifice some consistency and speed, making them a better choice for casual users with a limited budget. Evaluating value for money, vertical models offer long-term durability and precision, justifying the higher investment for frequent nut processing.

Best Nut Types for Each Chopper Style

Vertical choppers excel with harder nuts like almonds and walnuts due to their powerful downward slicing action, ensuring uniform pieces without crushing. Horizontal choppers work best for softer nuts such as cashews and pecans, offering a gentler chopping motion that preserves texture and prevents turning nuts into paste. Selecting the right chopper type enhances nut consistency for recipes, maximizing flavor and presentation.

Final Recommendation: Which Chopper Suits Your Needs?

Vertical choppers offer better control and uniformity for chopping nuts, making them ideal for precise kitchen tasks. Horizontal choppers excel in handling larger quantities quickly with powerful motor designs suited for bulk nut processing. Choose a vertical chopper for small-batch, consistency-focused needs, while a horizontal chopper is preferable for speed and volume in commercial or heavy-duty use.

Vertical Chopper vs Horizontal Chopper for Nuts Infographic

productvia.com

productvia.com