The basket lift system in deep fryers offers a hands-free, safer method by automatically raising and lowering the basket, reducing the risk of splashes and burns compared to manual lifting. Manual lifting requires more effort and increases exposure to hot oil, leading to potential accidents and uneven cooking. Investing in a basket lift system enhances precision and convenience during frying sessions.

Table of Comparison

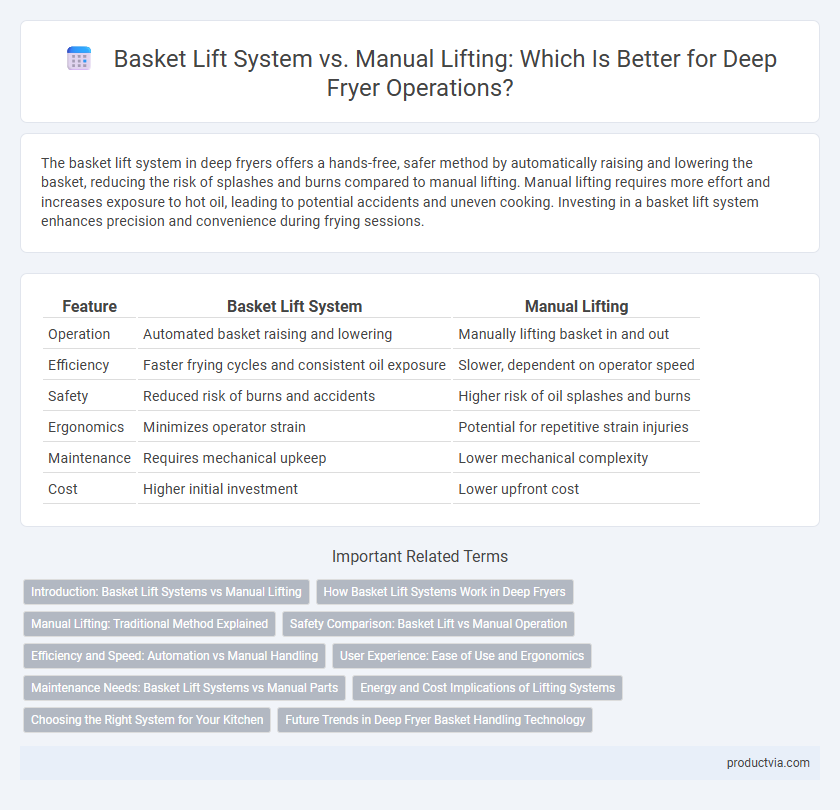

| Feature | Basket Lift System | Manual Lifting |

|---|---|---|

| Operation | Automated basket raising and lowering | Manually lifting basket in and out |

| Efficiency | Faster frying cycles and consistent oil exposure | Slower, dependent on operator speed |

| Safety | Reduced risk of burns and accidents | Higher risk of oil splashes and burns |

| Ergonomics | Minimizes operator strain | Potential for repetitive strain injuries |

| Maintenance | Requires mechanical upkeep | Lower mechanical complexity |

| Cost | Higher initial investment | Lower upfront cost |

Introduction: Basket Lift Systems vs Manual Lifting

Basket lift systems in deep fryers enhance safety and efficiency by automating basket raising and lowering, reducing operator strain and risk of accidents compared to manual lifting. These systems provide consistent frying times and temperature control, improving food quality and throughput in commercial kitchens. Manual lifting requires physical effort and careful timing, increasing the likelihood of burns and inconsistent cooking results.

How Basket Lift Systems Work in Deep Fryers

Basket lift systems in deep fryers automate the raising and lowering of frying baskets using an electric or hydraulic mechanism, ensuring consistent cooking times and reducing operator strain. These systems enhance safety by minimizing direct contact with hot oil and allow precise control over immersion depth and timing for uniform food crispness. Compared to manual lifting, basket lift systems improve efficiency and maintain product quality through repeatable, programmable motions.

Manual Lifting: Traditional Method Explained

Manual lifting in deep fryers involves physically raising and lowering the basket by hand, providing direct control over cooking time and food immersion. This traditional method requires operator attention to avoid overcooking or safety hazards such as oil splashes. Despite its simplicity, manual lifting demands skill and constant monitoring to ensure optimal frying results and safety compliance.

Safety Comparison: Basket Lift vs Manual Operation

The basket lift system in deep fryers significantly enhances safety by reducing direct contact with hot oil, minimizing the risk of burns and splashes compared to manual lifting. Automated lifting mechanisms provide controlled, smooth basket movements, preventing sudden drops or spills that often occur during manual operation. Ergonomic designs in basket lift systems also reduce operator fatigue, further decreasing the likelihood of accidents in industrial and commercial kitchen environments.

Efficiency and Speed: Automation vs Manual Handling

The basket lift system in deep fryers significantly improves efficiency and speed by automating the raising and lowering of baskets, reducing operator fatigue and minimizing cooking time variability. Manual lifting relies on physical effort, which can slow down the cooking process and introduce inconsistencies due to human error or fatigue. Automated basket lifts ensure precise timing and consistent frying results, enhancing productivity in high-volume food preparation environments.

User Experience: Ease of Use and Ergonomics

The basket lift system in deep fryers significantly enhances user experience by reducing physical strain and minimizing the risk of burns compared to manual lifting. Its ergonomic design allows for smooth, controlled basket raising and lowering, promoting safer and more efficient operation. This system improves ease of use, especially in high-volume kitchens, by streamlining repetitive tasks and reducing operator fatigue.

Maintenance Needs: Basket Lift Systems vs Manual Parts

Basket lift systems in deep fryers feature automated components requiring regular lubrication, inspection, and occasional motor servicing to prevent mechanical failure. Manual basket lifts involve simpler parts with minimal maintenance, primarily focusing on cleaning and checking for wear or corrosion. Choosing between the two depends on balancing advanced system upkeep against straightforward maintenance demands of manual parts.

Energy and Cost Implications of Lifting Systems

The Basket lift system in deep fryers reduces manual labor, leading to lower energy consumption by minimizing operator fatigue and improving workflow efficiency. Automated basket lifts typically incur higher upfront costs but decrease long-term expenses through consistent cooking times and reduced maintenance from avoidable human error. Manual lifting requires no additional energy input but increases labor costs and risks inconsistent cooking, impacting overall operational efficiency and cost-effectiveness.

Choosing the Right System for Your Kitchen

The basket lift system in deep fryers enhances safety and efficiency by automating the lifting and lowering process, reducing the risk of burns and repetitive strain injuries. Manual lifting requires more physical effort and attention, increasing the potential for accidents and inconsistent cooking results. Kitchens with high-volume frying operations benefit most from basket lift systems, while manual lifting may suffice for smaller, lower-frequency cooking environments.

Future Trends in Deep Fryer Basket Handling Technology

Emerging deep fryer basket lift systems incorporate automated mechanisms with precision sensors to enhance safety and efficiency while minimizing operator fatigue, representing a significant advancement over traditional manual lifting methods. Integration of IoT connectivity allows real-time monitoring of basket status, enabling predictive maintenance and optimizing frying cycles for consistent product quality. Future trends point towards fully robotic basket handling solutions that improve hygiene standards and streamline kitchen workflows in commercial foodservice operations.

Basket lift system vs manual lifting for deep fryer Infographic

productvia.com

productvia.com