Cold zone design in deep fryers creates a lower temperature area at the bottom of the oil, preventing food particles from burning and extending the oil's lifespan. Standard heating designs maintain a consistent temperature throughout, which can cause debris to burn and affect the flavor of fried foods. Choosing a cold zone deep fryer enhances cooking quality by reducing oil degradation and producing cleaner, crisper results.

Table of Comparison

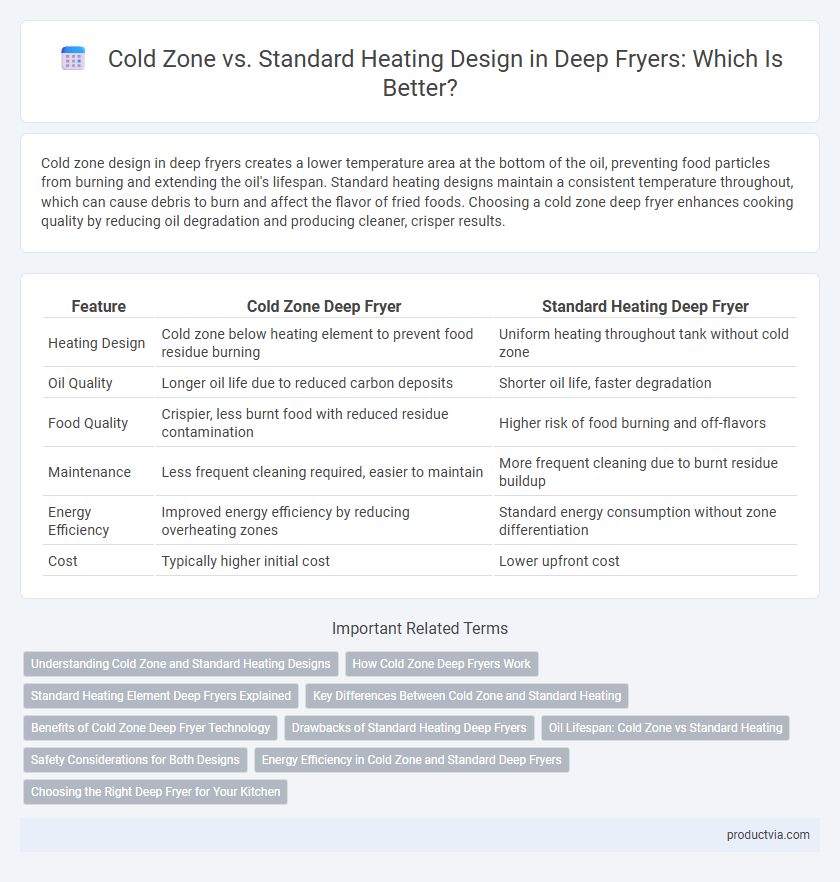

| Feature | Cold Zone Deep Fryer | Standard Heating Deep Fryer |

|---|---|---|

| Heating Design | Cold zone below heating element to prevent food residue burning | Uniform heating throughout tank without cold zone |

| Oil Quality | Longer oil life due to reduced carbon deposits | Shorter oil life, faster degradation |

| Food Quality | Crispier, less burnt food with reduced residue contamination | Higher risk of food burning and off-flavors |

| Maintenance | Less frequent cleaning required, easier to maintain | More frequent cleaning due to burnt residue buildup |

| Energy Efficiency | Improved energy efficiency by reducing overheating zones | Standard energy consumption without zone differentiation |

| Cost | Typically higher initial cost | Lower upfront cost |

Understanding Cold Zone and Standard Heating Designs

Cold zone deep fryer designs incorporate a cooler area at the bottom of the oil chamber to prevent food debris from burning, which extends oil life and improves fry quality. Standard heating designs distribute heat evenly throughout the oil, often resulting in faster cooking times but increased oil degradation due to burnt particles. Understanding these design differences is crucial for optimizing frying efficiency, oil maintenance, and final product taste in commercial kitchens.

How Cold Zone Deep Fryers Work

Cold zone deep fryers operate by creating a cooler area at the bottom of the oil vat, typically below the heating elements, where food debris settles without burning. This design prevents burnt particles from contaminating the oil, thus extending oil lifespan and improving food taste and hygiene. Standard heating deep fryers lack this feature, causing debris to burn and degrade oil quality more rapidly.

Standard Heating Element Deep Fryers Explained

Standard heating element deep fryers use immersed electric heating elements that directly transfer heat to the oil, ensuring rapid temperature recovery and consistent frying results. Unlike cold zone fryers, they lack a designated cooling area to trap food debris, which can lead to oil contamination over time but allows for more efficient heat distribution and faster cooking cycles. These fryers are ideal for high-volume kitchens requiring quick response times and stable oil temperatures to maintain food quality.

Key Differences Between Cold Zone and Standard Heating

Cold zone deep fryers feature a lower temperature area beneath the heating elements that captures food debris, preventing burning and maintaining oil quality longer. Standard heating designs heat the entire oil volume uniformly, which can cause food particles to burn and degrade oil faster. The cold zone design improves oil lifespan and food flavor, while standard fryers often require more frequent oil changes due to faster oil contamination.

Benefits of Cold Zone Deep Fryer Technology

Cold zone deep fryer technology features a designated cooler area beneath the heating element that traps food particles and sediment, preventing them from burning and contaminating the oil. This design extends oil life by reducing carbonization, which decreases oil degradation and lowers operational costs. The efficient sediment management also results in cleaner frying oil, enhancing food quality and safety compared to standard heating designs.

Drawbacks of Standard Heating Deep Fryers

Standard heating deep fryers often lack a cold zone, causing food particles to burn at the bottom due to constant high temperatures, which impairs oil quality and imparts off-flavors. This design accelerates oil degradation, leading to more frequent oil changes and increased operational costs. Without a cold zone to trap debris, these fryers also suffer from reduced oil longevity and increased maintenance requirements.

Oil Lifespan: Cold Zone vs Standard Heating

The cold zone design in deep fryers significantly extends oil lifespan by maintaining a lower temperature area at the bottom of the fry pot where food debris settles, preventing it from burning and contaminating the oil. Standard heating designs lack this cooler zone, causing food particles to burn rapidly, which accelerates oil degradation and reduces its effective usage time. As a result, fryers with cold zone technology require less frequent oil changes, lowering operational costs and improving frying performance.

Safety Considerations for Both Designs

Cold zone deep fryers incorporate a cooler area at the bottom of the oil tank to prevent food particles from burning, reducing the risk of oil degradation and fire hazards. Standard heating designs heat the entire oil volume uniformly, which may increase the likelihood of smoke and oil ignition if food debris accumulates and burns. Safety considerations emphasize proper maintenance and temperature control to minimize fire risks, with cold zone designs offering enhanced protection against oil contamination and overheating.

Energy Efficiency in Cold Zone and Standard Deep Fryers

Cold zone design in deep fryers improves energy efficiency by minimizing oil degradation and reducing heating cycles compared to standard heating models. This design maintains a cooler oil layer beneath the heating element, lowering the risk of burnt food particles and requiring less frequent oil changes, which conserves energy. Standard deep fryers often consume more power due to constant high-temperature operation and inefficient heat distribution.

Choosing the Right Deep Fryer for Your Kitchen

Cold zone deep fryer design traps sediment below the heating element, preventing burnt particles from contaminating oil and improving oil longevity, ideal for high-volume kitchens. Standard heating designs heat oil uniformly but allow debris to circulate, which can accelerate oil degradation and impact food quality. Selecting a deep fryer with a cold zone can reduce oil costs, enhance food taste, and streamline kitchen maintenance.

Cold zone vs standard heating design for deep fryer Infographic

productvia.com

productvia.com