Immersion heater elements provide rapid and even heat distribution by directly contacting the cooking oil, resulting in faster temperature recovery and consistent frying results. Tube-style heating elements, enclosed in metal tubes, offer durability and ease of cleaning but can heat oil less efficiently due to indirect heat transfer. Choosing between these designs depends on priorities like maintenance convenience versus optimal cooking performance for deep fryer pets.

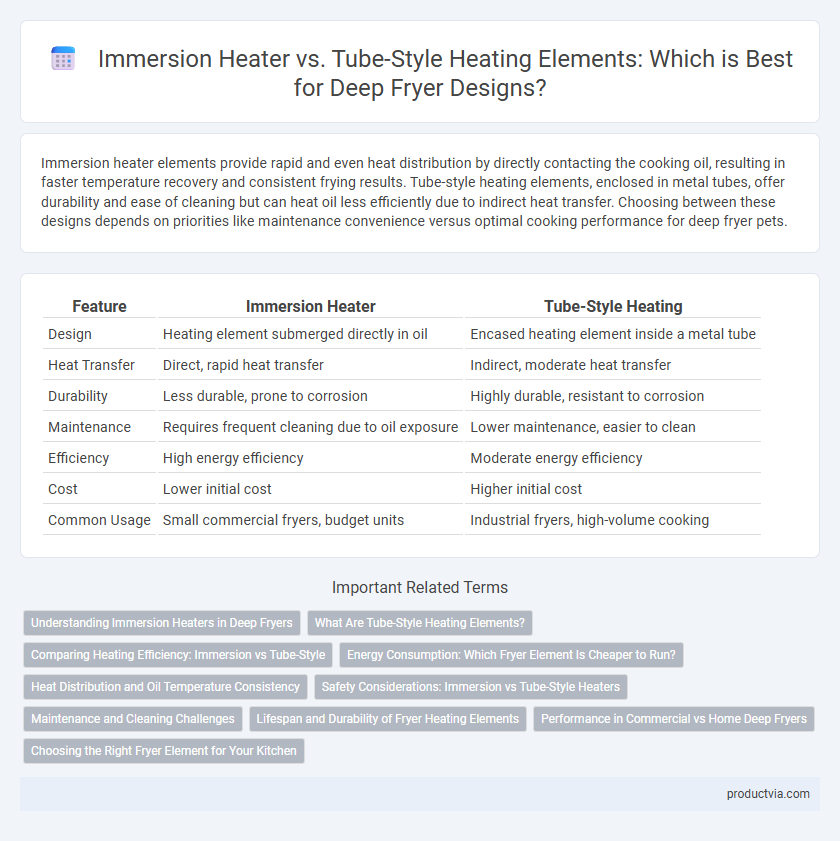

Table of Comparison

| Feature | Immersion Heater | Tube-Style Heating |

|---|---|---|

| Design | Heating element submerged directly in oil | Encased heating element inside a metal tube |

| Heat Transfer | Direct, rapid heat transfer | Indirect, moderate heat transfer |

| Durability | Less durable, prone to corrosion | Highly durable, resistant to corrosion |

| Maintenance | Requires frequent cleaning due to oil exposure | Lower maintenance, easier to clean |

| Efficiency | High energy efficiency | Moderate energy efficiency |

| Cost | Lower initial cost | Higher initial cost |

| Common Usage | Small commercial fryers, budget units | Industrial fryers, high-volume cooking |

Understanding Immersion Heaters in Deep Fryers

Immersion heaters in deep fryers consist of heating elements directly submerged in the cooking oil, enabling rapid and uniform heat transfer for consistent frying temperatures. This design minimizes energy loss by heating the oil directly, resulting in faster heat-up times compared to tube-style heating elements that transfer heat through metal tubes. Immersion heaters improve temperature control accuracy and reduce the risk of hot spots, ensuring better food quality and energy efficiency in commercial frying applications.

What Are Tube-Style Heating Elements?

Tube-style heating elements for deep fryers consist of sealed metal tubes that encase electrical resistance coils, providing efficient heat transfer and durability. These elements are designed to be immersed directly into the cooking oil, allowing rapid and consistent heating, which is essential for maintaining optimal frying temperatures. Their robust construction offers enhanced corrosion resistance and easier cleaning compared to immersion heaters with exposed coils.

Comparing Heating Efficiency: Immersion vs Tube-Style

Immersion heaters provide superior heating efficiency for deep fryers by directly contacting the oil, resulting in faster heat transfer and reduced energy loss. Tube-style heating elements heat indirectly through the fryer's metal walls, causing slower temperature responsiveness and potential heat dissipation. Choosing immersion heaters optimizes energy consumption and ensures consistent frying temperatures for improved cooking performance.

Energy Consumption: Which Fryer Element Is Cheaper to Run?

Immersion heater elements in deep fryers provide direct contact with the oil, resulting in faster heat transfer and typically lower energy consumption compared to tube-style heating elements. Tube-style heating elements, while robust and easier to maintain, often require more energy as heat must transfer through the metal surface before reaching the oil. Choosing immersion heaters can reduce operational costs by increasing energy efficiency and lowering electricity usage in commercial frying applications.

Heat Distribution and Oil Temperature Consistency

Immersion heater elements provide direct contact with the oil, resulting in rapid and even heat distribution that maintains consistent oil temperature during frying. Tube-style heating elements, while durable, often have less uniform heat transfer as heat must conduct through the metal tube before reaching the oil, potentially causing temperature fluctuations. Consistent oil temperature is critical for optimal frying quality, making immersion heaters preferable for commercial deep fryers focused on efficiency and product consistency.

Safety Considerations: Immersion vs Tube-Style Heaters

Immersion heaters for deep fryers offer direct heat transfer by being submerged in oil, reducing hot spot risks and promoting even heating, which enhances safety by minimizing oil degradation and fire hazards. Tube-style heating elements encapsulate metal tubes that keep the heating element separate from the oil, reducing direct contact and the risk of electrical faults, but may cause uneven heating and localized overheating if not properly designed. Choosing between immersion and tube-style heaters depends on balancing the benefits of direct heating efficiency against the potential safety risks related to element exposure and maintenance requirements in commercial fryer operations.

Maintenance and Cleaning Challenges

Immersion heaters in deep fryers offer straightforward maintenance since their heating elements are fully submerged, allowing for easier residue removal and prevention of oil buildup. Tube-style heating elements often require disassembly for proper cleaning due to their exposed design, which can trap food particles and increase downtime. Choosing immersion heaters reduces maintenance complexity, enhancing fryer efficiency and longevity by minimizing cleaning challenges associated with tube-style elements.

Lifespan and Durability of Fryer Heating Elements

Immersion heaters generally offer superior lifespan and durability since their heating elements are fully submerged in oil, ensuring consistent heat distribution and minimizing thermal stress. Tube-style heating elements, while easier to replace, are prone to faster wear due to exposure to fluctuating temperatures and potential oil contamination. Choosing immersion heater elements enhances long-term performance and reduces maintenance frequency in commercial deep fryers.

Performance in Commercial vs Home Deep Fryers

Immersion heaters provide rapid heat transfer by directly contacting the oil, resulting in faster heating times and better temperature control, which is crucial for commercial deep fryers operating at high capacities. Tube-style heating elements offer easier maintenance and durability, making them a popular choice for home deep fryers where lower power output and less frequent use reduce the need for intense performance. Commercial fryers prioritize energy efficiency and consistent cooking temperatures, favoring immersion heaters, while home models benefit from the simplicity and reliability of tube-style elements.

Choosing the Right Fryer Element for Your Kitchen

Immersion heaters offer rapid, direct heat transfer by submerging heating elements directly in oil, making them ideal for commercial kitchens requiring quick temperature recovery and energy efficiency. Tube-style heating elements, enclosed in metal tubing, provide durability and easier maintenance but may heat oil more slowly, suitable for smaller-scale or home kitchen fryers. Selecting the right fryer element depends on kitchen volume, desired heat-up time, and maintenance preferences, ensuring optimal frying performance and cost-effectiveness.

Immersion heater vs Tube-style heating for fryer element designs Infographic

productvia.com

productvia.com