Immersion heating elements in pet deep fryers provide faster and more efficient oil heating by being directly submerged, ensuring even temperature distribution and reduced heat loss. Covered heating elements, while safer and easier to clean, tend to heat oil more slowly due to indirect contact and can cause uneven heating. Choosing the right heating element impacts cooking performance, energy consumption, and maintenance requirements significantly.

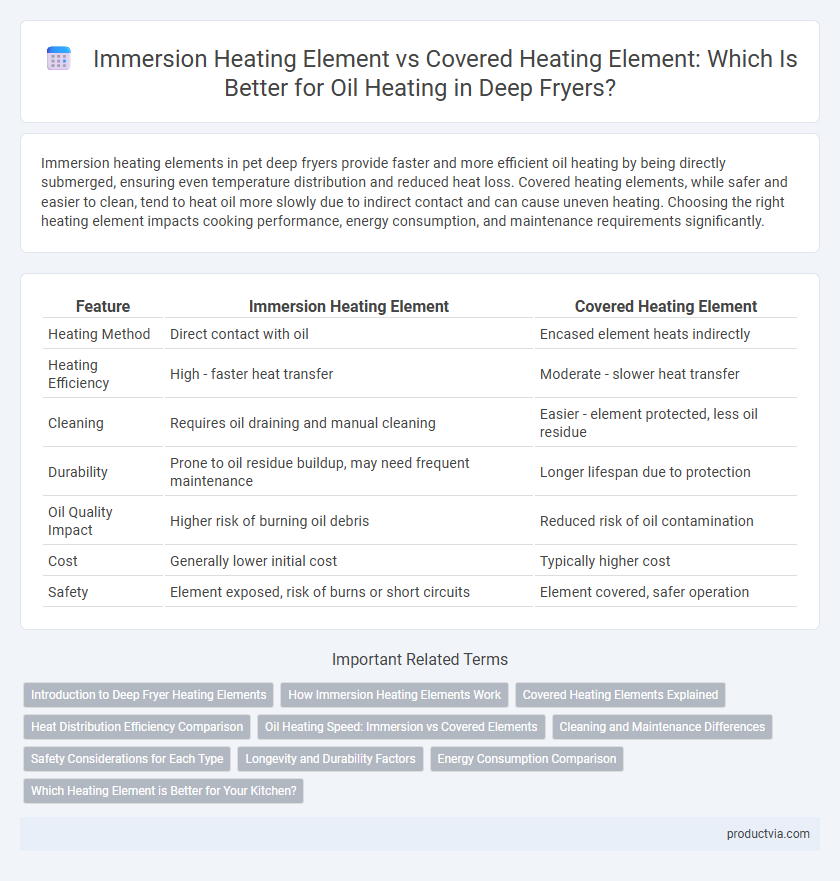

Table of Comparison

| Feature | Immersion Heating Element | Covered Heating Element |

|---|---|---|

| Heating Method | Direct contact with oil | Encased element heats indirectly |

| Heating Efficiency | High - faster heat transfer | Moderate - slower heat transfer |

| Cleaning | Requires oil draining and manual cleaning | Easier - element protected, less oil residue |

| Durability | Prone to oil residue buildup, may need frequent maintenance | Longer lifespan due to protection |

| Oil Quality Impact | Higher risk of burning oil debris | Reduced risk of oil contamination |

| Cost | Generally lower initial cost | Typically higher cost |

| Safety | Element exposed, risk of burns or short circuits | Element covered, safer operation |

Introduction to Deep Fryer Heating Elements

Immersion heating elements in deep fryers are directly submerged in oil, allowing rapid heat transfer and efficient temperature control, which enhances cooking speed and consistency. Covered heating elements, enclosed in a protective casing, offer easier cleaning and reduced oil contamination but may heat oil more slowly due to indirect contact. Choosing between immersion and covered elements impacts fryer performance, maintenance, and oil longevity crucial for commercial and home frying applications.

How Immersion Heating Elements Work

Immersion heating elements operate by being directly submerged in the cooking oil, allowing rapid and efficient heat transfer through direct contact with the liquid. This design minimizes energy loss and ensures consistent temperature control, making it ideal for deep fryers requiring precise oil heating. These elements are favored in commercial and high-performance fryers due to their quick heat-up times and uniform heat distribution.

Covered Heating Elements Explained

Covered heating elements in deep fryers are designed with a protective casing that prevents direct contact between the heating element and the oil, reducing the risk of burnt particles and ensuring more even heat distribution. This design enhances safety and simplifies cleaning by minimizing oil buildup and debris accumulation on the element. Compared to immersion heating elements, covered elements offer improved durability and consistent temperature control, making them ideal for commercial frying applications.

Heat Distribution Efficiency Comparison

Immersion heating elements in deep fryers provide direct contact with the oil, resulting in rapid and uniform heat distribution that minimizes hot spots and ensures consistent frying temperatures. Covered heating elements, while protected from direct oil exposure, often lead to slower heat transfer and uneven heating due to the insulating layer between the element and the oil. Efficiency in heat distribution is significantly higher with immersion heating elements, making them preferable for maintaining precise temperature control in commercial and home deep fryer applications.

Oil Heating Speed: Immersion vs Covered Elements

Immersion heating elements heat oil faster by being directly submerged, ensuring rapid and uniform heat transfer to the oil. Covered heating elements heat oil more slowly due to the barrier between the element and the oil, causing delayed heat conduction. Faster oil heating speed with immersion elements improves cooking efficiency and reduces preheat time in deep fryers.

Cleaning and Maintenance Differences

Immersion heating elements in deep fryers are submerged directly in the oil, allowing faster heat transfer but requiring frequent cleaning to remove oil residues and prevent buildup. Covered heating elements, enclosed in a protective casing, reduce direct contact with oil, minimizing debris accumulation and making maintenance easier with less frequent cleaning. The choice impacts overall fryer hygiene, with covered elements typically extending intervals between deep cleans and reducing maintenance labor.

Safety Considerations for Each Type

Immersion heating elements in deep fryers offer faster heat transfer by being directly submerged in the oil, but they require precise temperature control to prevent overheating and potential oil fires. Covered heating elements provide a safer operation by isolating the heating surface from direct oil contact, reducing risks of oil contamination and minimizing fire hazards. Proper maintenance and monitoring are crucial for both types to ensure safety and prolong the lifespan of the fryer.

Longevity and Durability Factors

Immersion heating elements, submerged directly in the oil, offer superior heat transfer efficiency and faster heating times, contributing to enhanced energy savings and consistent cooking results. Covered heating elements are easier to clean and less prone to oil buildup, but may experience reduced heat transfer efficiency, potentially leading to uneven heating and increased wear over time. In terms of longevity and durability, immersion elements generally withstand prolonged exposure to high temperatures better, while covered elements benefit from added protection against direct oil contact, extending their lifespan under moderate usage.

Energy Consumption Comparison

Immersion heating elements in deep fryers provide direct contact with the oil, resulting in faster heat transfer and lower energy consumption compared to covered heating elements, which are insulated and take longer to heat the oil indirectly. Studies indicate immersion elements can reduce energy use by up to 25% due to improved thermal efficiency and quicker recovery times. Covered elements, while protecting the heating element from food debris, often require longer cooking times, increasing overall energy consumption.

Which Heating Element is Better for Your Kitchen?

Immersion heating elements heat oil directly by being submerged, offering faster and more efficient heat transfer, ideal for commercial kitchens requiring quick temperature recovery. Covered heating elements are encased to prevent direct contact with oil, reducing buildup and making cleaning easier, suitable for home kitchens prioritizing maintenance. Choosing the right heating element depends on your kitchen's volume and cleaning preferences, with immersion elements excelling in speed and covered elements excelling in convenience.

Immersion heating element vs Covered heating element for oil heating Infographic

productvia.com

productvia.com