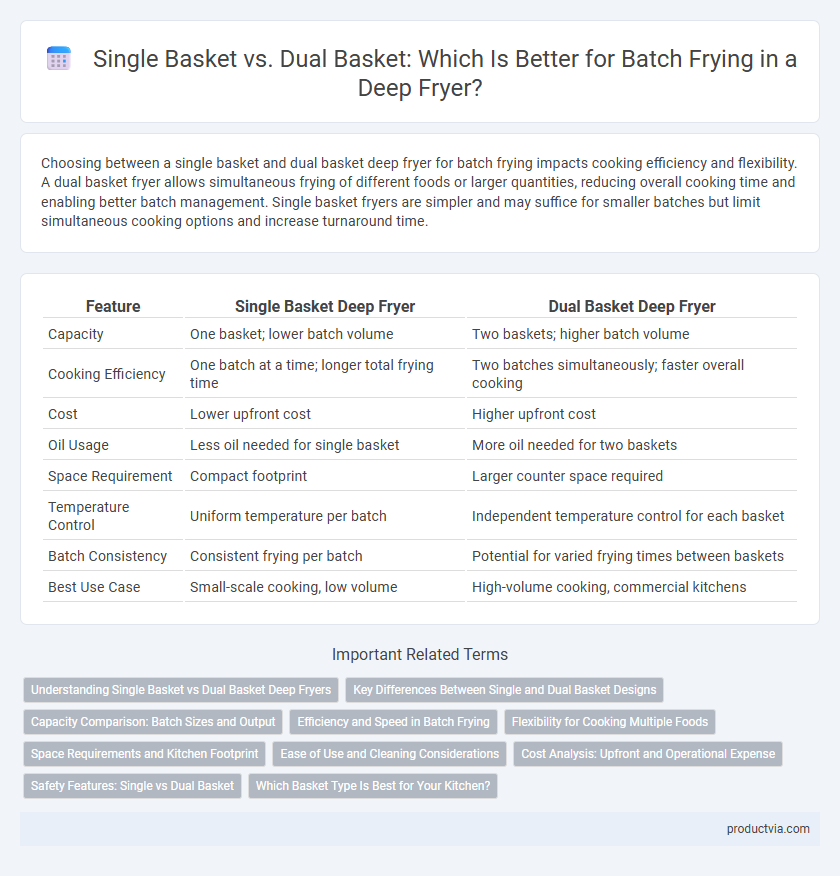

Choosing between a single basket and dual basket deep fryer for batch frying impacts cooking efficiency and flexibility. A dual basket fryer allows simultaneous frying of different foods or larger quantities, reducing overall cooking time and enabling better batch management. Single basket fryers are simpler and may suffice for smaller batches but limit simultaneous cooking options and increase turnaround time.

Table of Comparison

| Feature | Single Basket Deep Fryer | Dual Basket Deep Fryer |

|---|---|---|

| Capacity | One basket; lower batch volume | Two baskets; higher batch volume |

| Cooking Efficiency | One batch at a time; longer total frying time | Two batches simultaneously; faster overall cooking |

| Cost | Lower upfront cost | Higher upfront cost |

| Oil Usage | Less oil needed for single basket | More oil needed for two baskets |

| Space Requirement | Compact footprint | Larger counter space required |

| Temperature Control | Uniform temperature per batch | Independent temperature control for each basket |

| Batch Consistency | Consistent frying per batch | Potential for varied frying times between baskets |

| Best Use Case | Small-scale cooking, low volume | High-volume cooking, commercial kitchens |

Understanding Single Basket vs Dual Basket Deep Fryers

Single basket deep fryers are ideal for small batches and offer simplicity in operation, making them suitable for home use or low-volume cooking. Dual basket deep fryers allow simultaneous frying of different foods, increasing efficiency and batch capacity, which is essential in commercial kitchens or busy food service environments. Choosing between single and dual basket models depends on factors like cooking volume, space availability, and menu variety, directly impacting batch frying performance and turnaround time.

Key Differences Between Single and Dual Basket Designs

Single basket deep fryers are designed for smaller batches, offering simplicity and easier cleaning, which suits low-volume frying needs. Dual basket models allow simultaneous frying of different foods or larger quantities, improving efficiency and reducing cooking time in commercial kitchens. Key differences include batch capacity, cooking versatility, and operational speed, making dual basket fryers ideal for high-demand environments.

Capacity Comparison: Batch Sizes and Output

Single basket deep fryers typically offer smaller batch sizes, making them ideal for low to moderate volume frying with capacity ranging from 1 to 3 liters. Dual basket fryers provide significantly larger combined capacity, often doubling the output by allowing simultaneous frying of two separate batches, which enhances efficiency and throughput in high-demand environments. The choice between single and dual basket models directly impacts batch sizes, cooking speed, and overall productivity in commercial kitchens.

Efficiency and Speed in Batch Frying

Dual basket deep fryers significantly enhance efficiency and speed in batch frying by allowing simultaneous cooking of different food items or larger quantities, reducing overall cooking time. Single basket fryers limit capacity and require sequential frying batches, which can slow down kitchen workflow during peak hours. Investing in a dual basket model maximizes throughput and minimizes wait times, essential for high-volume foodservice operations.

Flexibility for Cooking Multiple Foods

Dual basket deep fryers offer greater flexibility for cooking multiple foods simultaneously, allowing different items to be fried at varying temperatures without flavor transfer. Single basket fryers limit batch sizes and require sequential cooking, which can increase wait times and reduce kitchen efficiency. Choosing a dual basket model enhances throughput and ensures better control over cooking times for diverse menu items.

Space Requirements and Kitchen Footprint

Single basket deep fryers require less counter space and have a smaller kitchen footprint, making them ideal for compact kitchens or limited work areas. Dual basket fryers, while occupying more space, allow simultaneous batch frying of different items, increasing efficiency and throughput in busy commercial kitchens. Choosing between single and dual baskets depends on balancing space constraints with the need for higher frying capacity and workflow optimization.

Ease of Use and Cleaning Considerations

Single basket deep fryers offer straightforward operation and simplified cleaning due to fewer components, making them ideal for smaller batches or occasional use. Dual basket models increase efficiency by allowing simultaneous frying of different foods, but require more effort in cleaning both baskets and additional surfaces. Users should weigh the convenience of a single basket against the productivity gains of dual baskets while considering the time involved in maintenance.

Cost Analysis: Upfront and Operational Expense

Single basket deep fryers typically have a lower upfront cost, making them ideal for small-scale operations or limited budgets. Dual basket models, although more expensive initially, offer increased capacity and efficiency, which can reduce operational costs by minimizing frying time and energy consumption during batch frying. Over time, the dual basket fryer's ability to handle larger volumes may lead to better cost-effectiveness despite higher initial investment.

Safety Features: Single vs Dual Basket

Single basket deep fryers reduce the risk of oil splatter and burns by limiting the amount of hot oil exposed at one time, enhancing user safety during batch frying. Dual basket models often incorporate safety features such as separate handles and lids to allow simultaneous frying with minimized cross-contamination and safer handling. Both configurations typically include automatic shut-off and temperature control to prevent overheating, but dual basket fryers require cautious operation to manage increased oil volumes safely.

Which Basket Type Is Best for Your Kitchen?

Single basket deep fryers offer simplicity and are ideal for kitchens with low to moderate frying volume, providing consistent heat distribution for uniform cooking. Dual basket models enhance efficiency by allowing simultaneous frying of different items or larger batches, reducing wait times and increasing output in busy commercial kitchens. Choosing between single and dual baskets depends on your kitchen's volume requirements, menu variety, and available space for optimal workflow.

Single basket vs Dual basket for batch frying Infographic

productvia.com

productvia.com