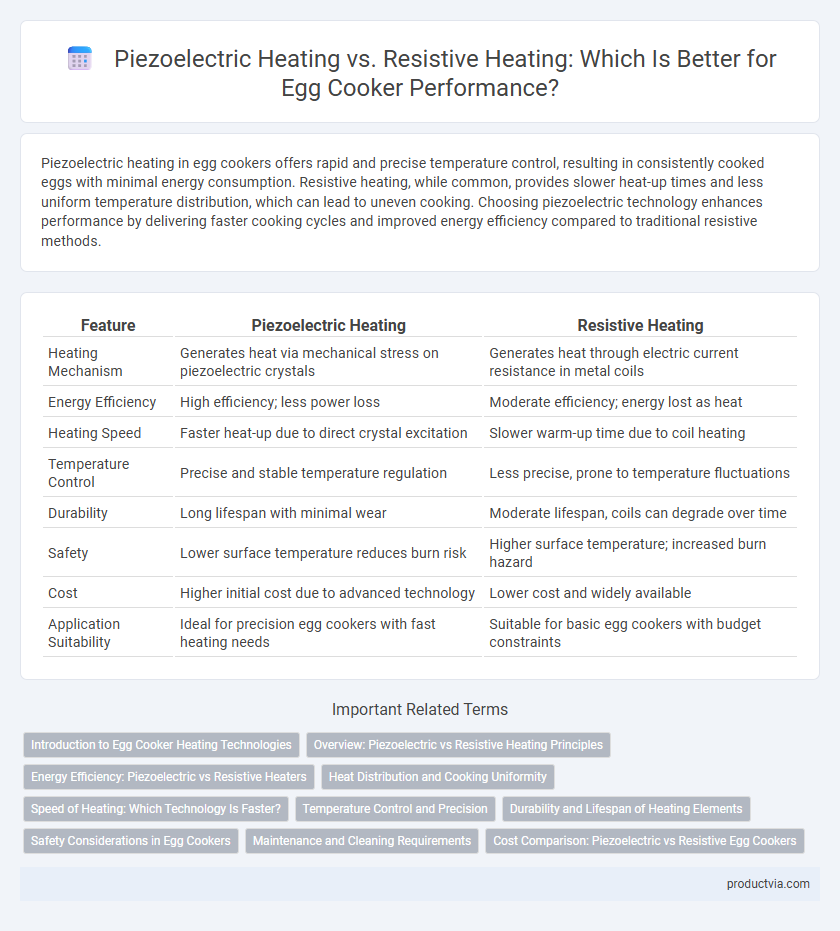

Piezoelectric heating in egg cookers offers rapid and precise temperature control, resulting in consistently cooked eggs with minimal energy consumption. Resistive heating, while common, provides slower heat-up times and less uniform temperature distribution, which can lead to uneven cooking. Choosing piezoelectric technology enhances performance by delivering faster cooking cycles and improved energy efficiency compared to traditional resistive methods.

Table of Comparison

| Feature | Piezoelectric Heating | Resistive Heating |

|---|---|---|

| Heating Mechanism | Generates heat via mechanical stress on piezoelectric crystals | Generates heat through electric current resistance in metal coils |

| Energy Efficiency | High efficiency; less power loss | Moderate efficiency; energy lost as heat |

| Heating Speed | Faster heat-up due to direct crystal excitation | Slower warm-up time due to coil heating |

| Temperature Control | Precise and stable temperature regulation | Less precise, prone to temperature fluctuations |

| Durability | Long lifespan with minimal wear | Moderate lifespan, coils can degrade over time |

| Safety | Lower surface temperature reduces burn risk | Higher surface temperature; increased burn hazard |

| Cost | Higher initial cost due to advanced technology | Lower cost and widely available |

| Application Suitability | Ideal for precision egg cookers with fast heating needs | Suitable for basic egg cookers with budget constraints |

Introduction to Egg Cooker Heating Technologies

Piezoelectric heating in egg cookers leverages the conversion of mechanical stress into heat, offering rapid and precise temperature control for consistent cooking results. Resistive heating relies on electrical resistance to generate heat through metal coils, ensuring reliable and evenly distributed warmth for thorough egg preparation. Comparing these technologies highlights piezoelectric heating's energy efficiency and faster response times against resistive heating's durability and widespread use in conventional egg cookers.

Overview: Piezoelectric vs Resistive Heating Principles

Piezoelectric heating in egg cookers utilizes materials that generate heat through mechanical stress-induced electric charge, enabling precise temperature control and rapid response time. Resistive heating relies on electric current passing through a high-resistance element, producing consistent and uniform heat distribution. Comparing the two, piezoelectric heating offers energy efficiency and targeted warmth, while resistive heating ensures durability and widespread application in egg cooker designs.

Energy Efficiency: Piezoelectric vs Resistive Heaters

Piezoelectric heating in egg cookers offers higher energy efficiency compared to traditional resistive heating by converting electrical energy into localized mechanical vibrations, which generate heat with minimal energy loss. Resistive heaters rely on electrical resistance to produce heat, often resulting in greater energy consumption and slower heating times. Leveraging piezoelectric technology reduces power usage and enhances cooking speed, making it a superior choice for energy-efficient egg cookers.

Heat Distribution and Cooking Uniformity

Piezoelectric heating in egg cookers offers rapid and precise temperature control, resulting in more consistent heat distribution throughout the cooking chamber. In contrast, resistive heating elements tend to create hotspots, leading to uneven cooking and potential overcooked edges. The enhanced uniformity provided by piezoelectric technology ensures perfectly cooked eggs with consistent texture and doneness.

Speed of Heating: Which Technology Is Faster?

Piezoelectric heating in egg cookers generates heat rapidly by converting mechanical energy into thermal energy through vibrations, enabling faster temperature rise compared to resistive heating elements that rely on electrical resistance to produce heat. This rapid energy conversion allows piezoelectric systems to reduce cooking times significantly, enhancing overall speed of heating performance. Resistive heating, while reliable, generally requires more time to reach optimal cooking temperatures due to slower heat transfer rates.

Temperature Control and Precision

Piezoelectric heating in egg cookers offers superior temperature control by generating heat through mechanical stress, enabling rapid and precise adjustments compared to traditional resistive heating elements. Resistive heating relies on electrical resistance to produce heat, which often results in slower response times and less consistent temperature regulation, impacting cooking precision. Enhanced temperature stability with piezoelectric technology ensures optimal heat distribution and reduces the risk of overcooking or undercooking eggs, improving overall cooker performance.

Durability and Lifespan of Heating Elements

Piezoelectric heating elements in egg cookers exhibit greater durability due to their solid-state design, which reduces wear and tear compared to resistive heating coils prone to oxidation and corrosion. The lifespan of piezoelectric elements often surpasses resistive counterparts by maintaining consistent heat output without significant degradation over time. Resistive heating elements may require more frequent replacement, negatively impacting the long-term reliability of the egg cooker.

Safety Considerations in Egg Cookers

Piezoelectric heating in egg cookers offers enhanced safety by generating heat through mechanical stress without direct electrical contact, minimizing the risk of electrical shock. Resistive heating involves electric current passing through resistive elements, which can overheat and pose fire hazards if not properly managed. Choosing piezoelectric heating technology can reduce safety risks associated with overheating and electrical faults in egg cookers.

Maintenance and Cleaning Requirements

Piezoelectric heating in egg cookers offers lower maintenance due to its solid-state design, minimizing wear and reducing residue buildup compared to resistive heating elements. Resistive heating often requires more frequent cleaning to prevent scale and mineral deposits that impair performance and longevity. The durability of piezoelectric systems translates to easier upkeep and consistent heating efficiency over time.

Cost Comparison: Piezoelectric vs Resistive Egg Cookers

Piezoelectric egg cookers generally have higher initial costs due to advanced materials and manufacturing complexity, whereas resistive egg cookers benefit from lower production expenses and widespread market availability. Operational efficiency in piezoelectric models can reduce energy consumption, potentially offsetting upfront costs over time compared to resistive heating elements that may consume more power during cooking cycles. Maintenance and lifespan of piezoelectric egg cookers also influence total cost of ownership, with resistive heaters often requiring more frequent replacement or repairs, affecting long-term expenses.

Piezoelectric heating vs resistive heating for egg cooker performance Infographic

productvia.com

productvia.com