Ceramic coating on electric skillets offers a non-toxic, scratch-resistant surface that provides even heating and easy cleaning, making it ideal for health-conscious users. Teflon coating is known for its excellent non-stick properties but may release harmful fumes at high temperatures and can be less durable over time. Choosing between ceramic and Teflon coatings depends on prioritizing safety and longevity versus superior non-stick performance.

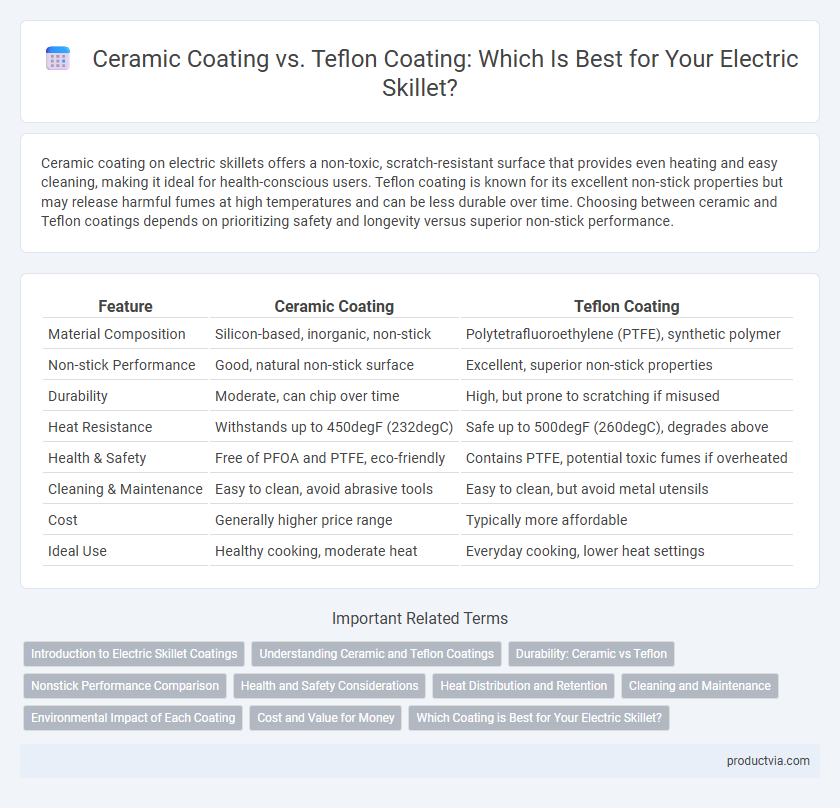

Table of Comparison

| Feature | Ceramic Coating | Teflon Coating |

|---|---|---|

| Material Composition | Silicon-based, inorganic, non-stick | Polytetrafluoroethylene (PTFE), synthetic polymer |

| Non-stick Performance | Good, natural non-stick surface | Excellent, superior non-stick properties |

| Durability | Moderate, can chip over time | High, but prone to scratching if misused |

| Heat Resistance | Withstands up to 450degF (232degC) | Safe up to 500degF (260degC), degrades above |

| Health & Safety | Free of PFOA and PTFE, eco-friendly | Contains PTFE, potential toxic fumes if overheated |

| Cleaning & Maintenance | Easy to clean, avoid abrasive tools | Easy to clean, but avoid metal utensils |

| Cost | Generally higher price range | Typically more affordable |

| Ideal Use | Healthy cooking, moderate heat | Everyday cooking, lower heat settings |

Introduction to Electric Skillet Coatings

Electric skillet coatings primarily include ceramic and Teflon, each offering unique benefits for cooking performance and durability. Ceramic coatings provide a non-stick surface free from PTFE and PFOA chemicals, promoting healthier cooking and higher heat resistance. Teflon coatings, made from polytetrafluoroethylene (PTFE), offer excellent non-stick properties and easy food release but require careful use to avoid high-temperature damage.

Understanding Ceramic and Teflon Coatings

Ceramic coatings on electric skillets offer a non-stick surface made from inorganic minerals, providing superior heat resistance and eco-friendly properties compared to Teflon coatings, which consist of polytetrafluoroethylene (PTFE) known for its slippery surface but potential to release harmful fumes at high temperatures. Ceramic coatings tend to be more durable and scratch-resistant, making them suitable for frequent use with metal utensils, whereas Teflon coatings require gentler handling and tend to degrade faster with heavy use. Choosing between ceramic and Teflon coatings involves balancing durability, non-stick efficiency, and safety considerations for optimal cooking performance.

Durability: Ceramic vs Teflon

Ceramic coatings on electric skillets generally offer superior durability due to their resistance to scratches and higher heat tolerance, making them less prone to wear over time compared to Teflon coatings. Teflon coatings, while excellent for non-stick performance, tend to degrade faster when exposed to high temperatures or metal utensils, leading to peeling and reduced effectiveness. Investing in ceramic-coated electric skillets ensures longer-lasting non-stick properties and better resilience under frequent cooking conditions.

Nonstick Performance Comparison

Ceramic coatings on electric skillets provide excellent nonstick performance while being free from harmful chemicals like PTFE and PFOA, making them safer for high-temperature cooking. Teflon coatings offer superior initial nonstick properties with smooth food release but can degrade faster under high heat or metal utensil use, losing effectiveness over time. Consumers seeking durability and safer materials often prefer ceramic coatings, whereas those prioritizing effortless food release might favor Teflon despite its shorter lifespan.

Health and Safety Considerations

Ceramic coatings on electric skillets are free from toxic chemicals like PTFE and PFOA, reducing health risks commonly associated with overheating Teflon coatings. Teflon-coated skillets can release harmful fumes when heated beyond 500degF, posing respiratory hazards, whereas ceramic coatings offer higher heat resistance and safer cooking temperatures. Choosing ceramic-coated electric skillets supports a non-toxic cooking environment and better long-term health safety.

Heat Distribution and Retention

Ceramic coating in electric skillets offers superior heat distribution due to its even thermal conductivity, ensuring consistent cooking without hot spots. This coating also retains heat effectively, allowing for stable cooking temperatures and energy efficiency. In contrast, Teflon coating provides rapid heat-up times but may have less uniform heat distribution and lower heat retention, which can affect cooking performance.

Cleaning and Maintenance

Ceramic coatings on electric skillets offer superior non-stick properties that make cleaning easier by preventing food from sticking and reducing residue buildup. Teflon coatings also provide non-stick surfaces but require more careful maintenance to avoid scratches and peeling, which can compromise the coating's effectiveness. Regular gentle cleaning with non-abrasive materials is essential for both coatings to maintain their durability and performance over time.

Environmental Impact of Each Coating

Ceramic coating on electric skillets is made from natural minerals and is generally considered more environmentally friendly due to its non-toxic, recyclable properties and lack of harmful chemical emissions during production. Teflon coating, derived from perfluorooctanoic acid (PFOA), raises environmental concerns because of its persistence in ecosystems and potential to release toxic compounds when overheated or disposed improperly. Choosing ceramic-coated skillets supports sustainability by reducing chemical pollution and promoting safer manufacturing processes.

Cost and Value for Money

Ceramic coating electric skillets generally cost more upfront but offer superior heat distribution and are free from harmful chemicals, providing long-term value through durability and healthier cooking. Teflon-coated skillets are typically more affordable and widely available but may degrade faster and release harmful fumes if overheated, potentially reducing their overall value. When evaluating cost and value for money, ceramic coatings deliver better longevity and safety, making them a worthwhile investment despite their higher price.

Which Coating is Best for Your Electric Skillet?

Ceramic coating offers a non-toxic, eco-friendly surface that withstands high temperatures and resists scratching, making it ideal for health-conscious users. Teflon coating provides superior non-stick performance with easy food release and quick cleanup but may degrade under very high heat or if scratched. For electric skillets, ceramic coating is best for durability and safety, while Teflon suits those prioritizing effortless cooking and maintenance.

Ceramic coating vs Teflon coating for electric skillet Infographic

productvia.com

productvia.com