Cool-touch handles on electric skillets provide enhanced safety by remaining cool to the touch during cooking, reducing the risk of burns compared to standard handles that can become hot. These handles improve handling comfort and prevent accidental slips, especially when moving the skillet. Choosing an electric skillet with cool-touch handles ensures safer cooking, particularly in busy kitchens or during high-temperature use.

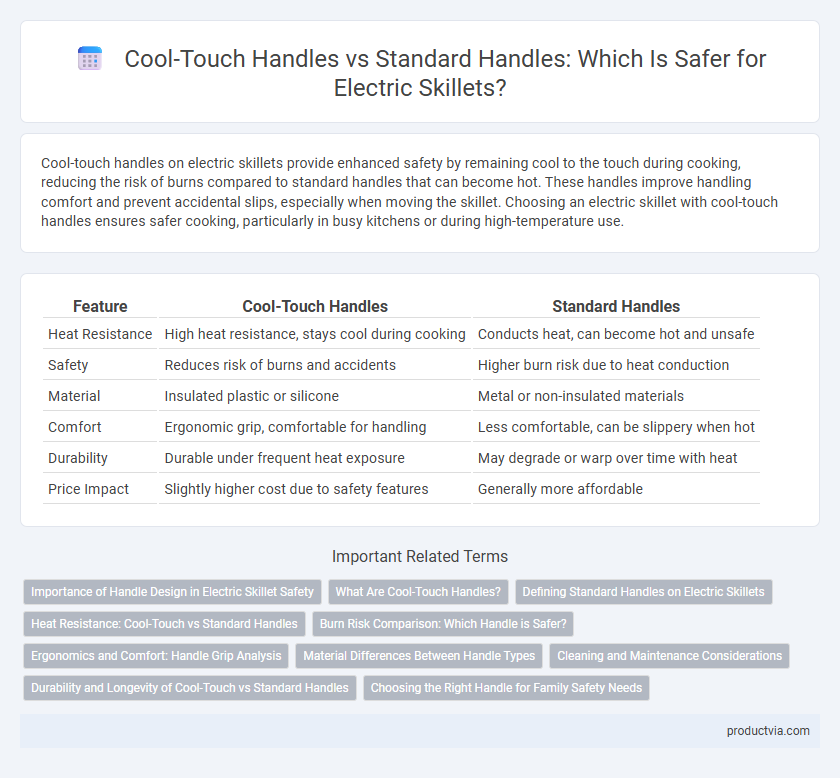

Table of Comparison

| Feature | Cool-Touch Handles | Standard Handles |

|---|---|---|

| Heat Resistance | High heat resistance, stays cool during cooking | Conducts heat, can become hot and unsafe |

| Safety | Reduces risk of burns and accidents | Higher burn risk due to heat conduction |

| Material | Insulated plastic or silicone | Metal or non-insulated materials |

| Comfort | Ergonomic grip, comfortable for handling | Less comfortable, can be slippery when hot |

| Durability | Durable under frequent heat exposure | May degrade or warp over time with heat |

| Price Impact | Slightly higher cost due to safety features | Generally more affordable |

Importance of Handle Design in Electric Skillet Safety

Cool-touch handles enhance electric skillet safety by minimizing the risk of burns during cooking, providing a secure grip even when the skillet is hot. Standard handles often retain heat, posing a higher danger of accident or injury. Prioritizing cool-touch handle design is essential for preventing burns and ensuring safer kitchen operation.

What Are Cool-Touch Handles?

Cool-touch handles on electric skillets are designed with heat-resistant materials that prevent the handles from becoming hot during cooking, significantly reducing the risk of burns. Unlike standard handles that can rapidly heat up and require the use of oven mitts or pot holders, cool-touch handles maintain a safe temperature for direct handling. This safety feature enhances user confidence and convenience, making them an essential consideration for electric skillet safety.

Defining Standard Handles on Electric Skillets

Standard handles on electric skillets are typically made from heat-resistant but not fully insulated materials, which can become hot during extended cooking, posing a burn risk. Unlike cool-touch handles that incorporate advanced insulation technology to stay safe to touch, standard handles require caution and the use of oven mitts or potholders. Understanding these differences highlights the importance of handle design in preventing kitchen accidents while using electric skillets.

Heat Resistance: Cool-Touch vs Standard Handles

Cool-touch handles on electric skillets provide superior heat resistance, preventing burns by remaining cool even during high-temperature cooking. Standard handles often absorb and transfer heat, posing a safety risk that requires the use of pot holders. Choosing cool-touch handles enhances user safety by minimizing direct contact with hot surfaces, ensuring a safer cooking experience.

Burn Risk Comparison: Which Handle is Safer?

Cool-touch handles on electric skillets significantly reduce burn risk by staying insulated from heat, preventing direct contact burns during cooking. Standard handles often absorb heat, increasing the likelihood of accidental burns without protective gloves or mitts. For maximum safety, electric skillets with cool-touch handles offer superior protection against burn injuries compared to standard handles.

Ergonomics and Comfort: Handle Grip Analysis

Cool-touch handles on electric skillets enhance safety by remaining at a lower temperature during use, reducing the risk of burns. Ergonomically designed grips on these handles provide better comfort and control, minimizing hand fatigue during cooking. Standard handles often lack this temperature insulation and ergonomic shaping, making them less comfortable and potentially hazardous during extended use.

Material Differences Between Handle Types

Cool-touch handles on electric skillets are typically made from heat-resistant materials such as silicone or thermoplastic, which provide insulation and prevent burns during cooking. Standard handles often use metal components that conduct heat, increasing the risk of injury if touched without protection. The choice of handle material directly impacts user safety by minimizing heat transfer and enhancing grip stability.

Cleaning and Maintenance Considerations

Cool-touch handles on electric skillets enhance safety by preventing burns during cleaning and maintenance, allowing users to handle the skillet without waiting for it to cool down completely. These handles are typically made from heat-resistant materials that resist damage from water and cleaning agents, ensuring durability and ease of maintenance. In contrast, standard handles may become hot, increasing the risk of burns and complicating safe handling during cleaning, which can deter thorough maintenance and potentially shorten the skillet's lifespan.

Durability and Longevity of Cool-Touch vs Standard Handles

Cool-touch handles on electric skillets are designed with heat-resistant materials that enhance durability by preventing warping and cracking over time caused by repeated exposure to high temperatures. Standard handles, often made from basic plastic or metal, tend to degrade faster due to heat damage, compromising their safety and lifespan. Investing in cool-touch handles ensures longer-lasting performance and safer handling during extended cooking sessions.

Choosing the Right Handle for Family Safety Needs

Cool-touch handles on electric skillets provide essential protection against burns by remaining insulated and safe to touch even at high cooking temperatures, making them ideal for families with young children. Standard handles may heat up during use, increasing the risk of accidental contact burns and requiring extra caution. Prioritizing cool-touch handles enhances overall kitchen safety and reduces the likelihood of heat-related injuries in busy household environments.

Cool-touch handles vs Standard handles for electric skillet safety Infographic

productvia.com

productvia.com