Die-cast aluminum electric skillets offer superior heat distribution and durability compared to pressed aluminum models, ensuring even cooking and longer product lifespan. Pressed aluminum skillets are typically lighter and more affordable but may have thinner walls that heat unevenly or warp over time. Choosing die-cast aluminum provides consistent temperature control and better resistance to warping, making it ideal for precision cooking.

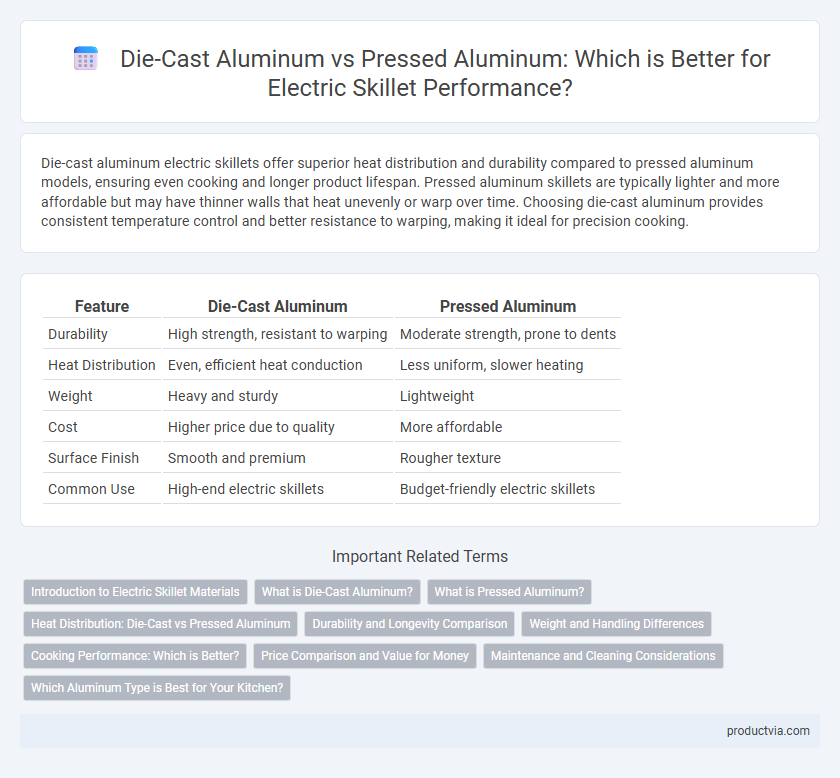

Table of Comparison

| Feature | Die-Cast Aluminum | Pressed Aluminum |

|---|---|---|

| Durability | High strength, resistant to warping | Moderate strength, prone to dents |

| Heat Distribution | Even, efficient heat conduction | Less uniform, slower heating |

| Weight | Heavy and sturdy | Lightweight |

| Cost | Higher price due to quality | More affordable |

| Surface Finish | Smooth and premium | Rougher texture |

| Common Use | High-end electric skillets | Budget-friendly electric skillets |

Introduction to Electric Skillet Materials

Die-cast aluminum offers superior durability and heat retention for electric skillets compared to pressed aluminum, providing even cooking temperatures and resistance to warping. Pressed aluminum is generally lighter and more affordable but may lack the structural strength and consistent heat distribution of die-cast varieties. Choosing the right material impacts the skillet's performance, longevity, and overall cooking experience.

What is Die-Cast Aluminum?

Die-cast aluminum is a manufacturing process where molten aluminum is forced into a steel mold under high pressure, resulting in a dense, durable, and lightweight cookware body for electric skillets. This method produces a smoother surface and superior heat retention compared to pressed aluminum, enhancing cooking performance and energy efficiency. Die-cast aluminum electric skillets often feature reinforced edges and non-stick coatings, making them resistant to warping and ideal for even heating.

What is Pressed Aluminum?

Pressed aluminum is a manufacturing process where aluminum sheets are shaped under high pressure into the desired form, offering lightweight and cost-effective cookware options. Unlike die-cast aluminum, which involves melting and casting molten aluminum into molds, pressed aluminum retains a thinner profile but provides good heat conductivity for electric skillets. This material is often used in electric skillets for affordability and quick heating, though it may lack the durability and even heat distribution of die-cast aluminum models.

Heat Distribution: Die-Cast vs Pressed Aluminum

Die-cast aluminum electric skillets offer superior heat distribution due to their denser, more uniform structure, which minimizes hot spots and ensures even cooking. Pressed aluminum pans tend to have thinner, less consistent thickness, resulting in uneven heating and potential hot zones. Choosing die-cast aluminum enhances cooking performance by maintaining stable temperatures and reducing energy waste.

Durability and Longevity Comparison

Die-cast aluminum offers superior durability and longevity compared to pressed aluminum due to its denser and more robust structure, which withstands high temperatures and heavy use without warping. Pressed aluminum tends to be thinner and less durable, making it more prone to dents and deformation over time. Electric skillets made from die-cast aluminum typically provide better heat retention and consistent cooking performance, enhancing their lifespan.

Weight and Handling Differences

Die-cast aluminum electric skillets offer superior weight distribution and sturdiness, resulting in a more balanced and stable cooking experience compared to pressed aluminum models. Pressed aluminum skillets tend to be lighter and easier to maneuver but may lack the structural rigidity and heat retention capabilities of die-cast versions. Choosing die-cast aluminum enhances durability and heat conduction, while pressed aluminum prioritizes portability and ease of handling.

Cooking Performance: Which is Better?

Die-cast aluminum electric skillets offer superior cooking performance due to their thicker, more uniform material, which ensures even heat distribution and retention, preventing hotspots and food burning. Pressed aluminum skillets heat up faster but often have thinner walls, leading to uneven cooking and less consistent temperature control. For precise and consistent cooking results, die-cast aluminum is generally preferred over pressed aluminum in electric skillets.

Price Comparison and Value for Money

Die-cast aluminum electric skillets generally cost more due to their denser material offering superior heat retention and even cooking, making them a durable investment. Pressed aluminum skillets are more affordable but may sacrifice some heat distribution efficiency and long-term durability. Considering price and value for money, die-cast aluminum models tend to offer better overall performance and longevity despite a higher upfront cost.

Maintenance and Cleaning Considerations

Die-cast aluminum electric skillets feature a smoother, non-porous surface that resists food sticking and simplifies cleaning, making maintenance less time-consuming compared to pressed aluminum. Pressed aluminum skillets may have a rougher texture that can trap food particles, requiring more thorough scrubbing and potential seasoning to maintain performance. Regular gentle cleaning and avoiding abrasive materials preserve the protective coating on die-cast aluminum, extending the skillet's lifespan and maintaining optimal cooking quality.

Which Aluminum Type is Best for Your Kitchen?

Die-cast aluminum offers superior heat distribution and durability for electric skillets, making it ideal for consistent cooking results and long-term use in your kitchen. Pressed aluminum skillets tend to be lighter and more affordable but often have uneven heat conduction and lower resistance to warping. Choosing die-cast aluminum ensures better performance and longevity, especially for frequent cooking tasks.

Die-cast aluminum vs Pressed aluminum for electric skillet Infographic

productvia.com

productvia.com