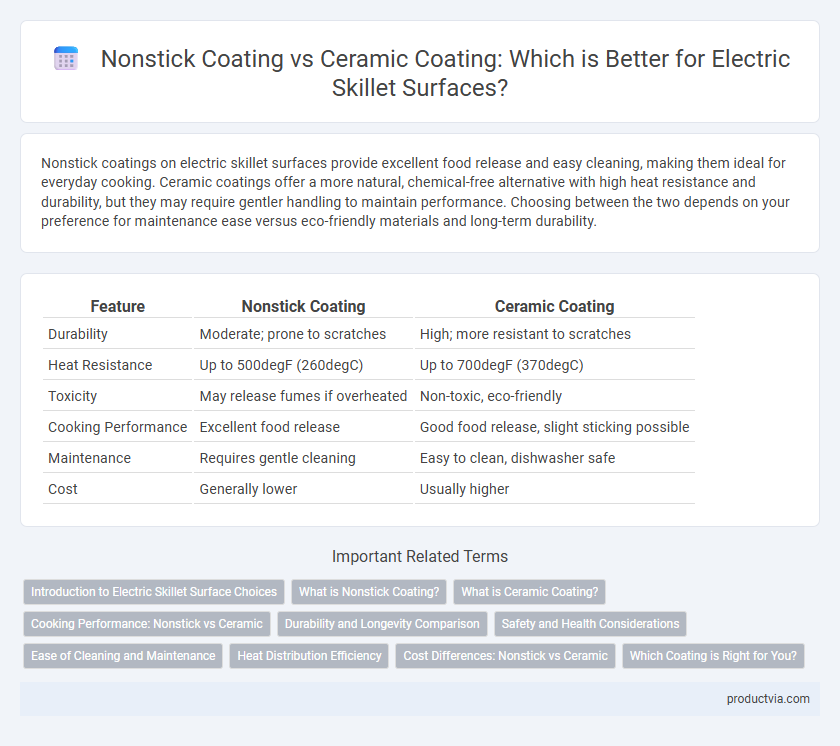

Nonstick coatings on electric skillet surfaces provide excellent food release and easy cleaning, making them ideal for everyday cooking. Ceramic coatings offer a more natural, chemical-free alternative with high heat resistance and durability, but they may require gentler handling to maintain performance. Choosing between the two depends on your preference for maintenance ease versus eco-friendly materials and long-term durability.

Table of Comparison

| Feature | Nonstick Coating | Ceramic Coating |

|---|---|---|

| Durability | Moderate; prone to scratches | High; more resistant to scratches |

| Heat Resistance | Up to 500degF (260degC) | Up to 700degF (370degC) |

| Toxicity | May release fumes if overheated | Non-toxic, eco-friendly |

| Cooking Performance | Excellent food release | Good food release, slight sticking possible |

| Maintenance | Requires gentle cleaning | Easy to clean, dishwasher safe |

| Cost | Generally lower | Usually higher |

Introduction to Electric Skillet Surface Choices

Electric skillet surfaces primarily feature nonstick and ceramic coatings, each offering unique benefits for cooking performance. Nonstick coatings provide excellent food release and easy cleanup, making them ideal for low-fat cooking and delicate foods. Ceramic coatings, known for their natural, chemical-free composition, offer high heat resistance and durability while maintaining a smooth, non-reactive cooking surface.

What is Nonstick Coating?

Nonstick coating on electric skillet surfaces typically consists of a synthetic polymer like polytetrafluoroethylene (PTFE), designed to prevent food from sticking and simplify cleaning. This coating provides excellent heat distribution and is resistant to scratches when used with appropriate utensils, enhancing cooking efficiency. Its chemical stability ensures minimal food residue buildup, making it a popular choice for everyday cooking with electric skillets.

What is Ceramic Coating?

Ceramic coating on electric skillet surfaces is a non-toxic, environmentally friendly layer made from inorganic materials that provides excellent heat resistance and even heat distribution. Unlike traditional nonstick coatings, ceramic coatings are free from PTFE and PFOA, reducing health risks and enhancing durability. This coating offers superior scratch resistance and maintains nonstick properties at higher cooking temperatures, making it ideal for healthier and versatile cooking.

Cooking Performance: Nonstick vs Ceramic

Nonstick coatings on electric skillets provide excellent food release and require less oil, enhancing cooking performance with even heat distribution and quick cleanup. Ceramic coatings offer superior heat tolerance and durability, allowing higher cooking temperatures without releasing harmful chemicals, which benefits searing and browning tasks. Both coatings improve cooking quality, but nonstick excels in ease of use while ceramic ceramic offers better longevity and health-conscious advantages.

Durability and Longevity Comparison

Nonstick coatings on electric skillet surfaces typically offer excellent initial release properties but tend to degrade faster under high heat, reducing durability and longevity. Ceramic coatings provide superior scratch resistance and maintain their nonstick qualities longer, even with frequent use and higher temperatures. Choosing ceramic-coated electric skillets can result in extended lifespan and more consistent cooking performance over time.

Safety and Health Considerations

Nonstick coatings on electric skillets typically contain PTFE, which is safe under normal cooking temperatures but can release harmful fumes if overheated above 500degF (260degC). Ceramic coatings, made from inorganic materials, offer a non-toxic surface that is free from chemicals like PFOA and PTFE, reducing health risks associated with high-heat cooking. Choosing ceramic coatings enhances safety by preventing chemical leaching and promoting toxin-free cooking environments.

Ease of Cleaning and Maintenance

Nonstick coating electric skillets typically offer easier cleaning due to their smooth, nonporous surface that resists food sticking, making maintenance quick with just a soft cloth and mild detergent. Ceramic coating skillets, while promoting healthier cooking without chemical additives, often require more careful cleaning to prevent chipping and maintain their protective layer, involving gentle scrubbing and avoiding abrasive tools. Both coatings demand regular upkeep for longevity, but nonstick surfaces generally lead to faster, hassle-free cleaning routines in daily use.

Heat Distribution Efficiency

Nonstick coatings typically offer superior heat distribution efficiency in electric skillet surfaces due to their smooth, uniform layer that allows even cooking. Ceramic coatings provide good heat resistance but may have slightly less efficient heat conduction compared to traditional nonstick surfaces. Choosing between the two depends on whether faster heat distribution or chemical-free material is the priority.

Cost Differences: Nonstick vs Ceramic

Nonstick coatings for electric skillet surfaces typically cost less upfront due to cheaper manufacturing processes and materials. Ceramic coatings, while initially more expensive, offer better durability and heat resistance that can lower replacement frequency and long-term expenses. Choosing between nonstick and ceramic impacts both initial investment and maintenance costs for electric skillet users.

Which Coating is Right for You?

Nonstick coatings on electric skillets provide excellent food release and easy cleanup, making them ideal for everyday cooking and low-fat meal preparation. Ceramic coatings offer a more environmentally friendly and chemical-free option, with higher heat tolerance suitable for searing and browning. Choose nonstick for convenience and durability or ceramic for a non-toxic surface and high-temperature performance based on your cooking style and health preferences.

Nonstick coating vs Ceramic coating for electric skillet surfaces Infographic

productvia.com

productvia.com