Direct drive food processors offer improved power transfer and durability by connecting the motor directly to the blade, resulting in faster and more efficient processing. Belt drive models use a belt to connect the motor and blade, which can reduce noise and provide some shock absorption but may wear out over time. Choosing between direct drive and belt drive depends on the need for longevity and power versus quieter operation and maintenance considerations.

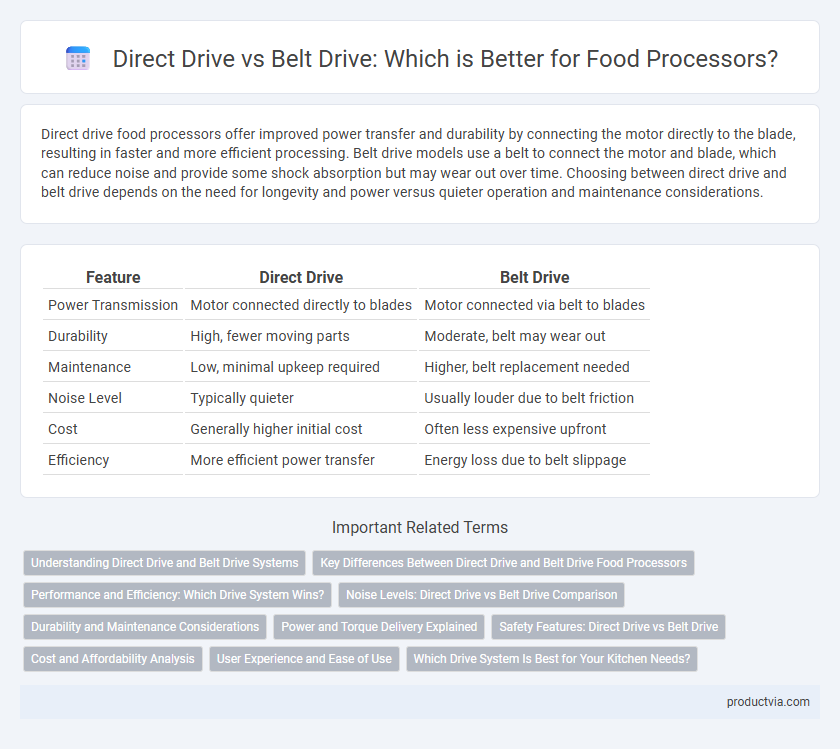

Table of Comparison

| Feature | Direct Drive | Belt Drive |

|---|---|---|

| Power Transmission | Motor connected directly to blades | Motor connected via belt to blades |

| Durability | High, fewer moving parts | Moderate, belt may wear out |

| Maintenance | Low, minimal upkeep required | Higher, belt replacement needed |

| Noise Level | Typically quieter | Usually louder due to belt friction |

| Cost | Generally higher initial cost | Often less expensive upfront |

| Efficiency | More efficient power transfer | Energy loss due to belt slippage |

Understanding Direct Drive and Belt Drive Systems

Direct drive food processors transfer power directly from the motor to the blade assembly, resulting in higher efficiency, reduced maintenance, and quieter operation compared to belt drive systems. Belt drive food processors use a belt and pulley mechanism, which can absorb motor vibrations and provide a smoother start but may require periodic belt replacements and adjustments. Understanding these differences helps users choose a system that fits their durability preferences and maintenance willingness.

Key Differences Between Direct Drive and Belt Drive Food Processors

Direct drive food processors feature a motor that connects directly to the blade assembly, providing greater power efficiency, quieter operation, and less maintenance compared to belt drive models. Belt drive food processors use a belt to transfer power from the motor to the blades, which can lead to more vibration and wear over time but often result in a lower initial cost. Key differences include durability, noise levels, power transmission efficiency, and long-term maintenance requirements.

Performance and Efficiency: Which Drive System Wins?

Direct drive food processors offer superior performance and efficiency by transmitting power directly from the motor to the blades, resulting in faster blade rotation and reduced energy loss. Belt drive systems, while typically quieter and more affordable, experience some energy dissipation and slower response times due to the additional belt mechanism. In terms of durability and consistent, high-speed operation, direct drive systems generally outperform belt drive counterparts in food processor applications.

Noise Levels: Direct Drive vs Belt Drive Comparison

Direct drive food processors typically generate less noise because the motor is directly connected to the blade, reducing vibrations that cause sound. Belt drive models often produce more noise due to belt slippage and additional components causing friction. Users seeking quieter operation often prefer direct drive systems for their smoother and more silent performance.

Durability and Maintenance Considerations

Direct drive food processors feature a motor directly connected to the blade assembly, resulting in increased durability due to fewer moving parts and reduced wear over time. Belt drive models require occasional belt replacement and more frequent maintenance to prevent slippage and ensure consistent performance. Choosing direct drive enhances longevity and minimizes upkeep, making it ideal for heavy or regular kitchen use.

Power and Torque Delivery Explained

Direct drive food processors deliver superior power and torque through a direct motor-to-blade connection, minimizing energy loss and enhancing efficiency. Belt drive systems use a belt to transfer motor power, which can reduce torque consistency and cause slippage under heavy loads. For tasks requiring sustained high torque, such as kneading dough or processing dense ingredients, direct drive models provide more reliable and powerful performance.

Safety Features: Direct Drive vs Belt Drive

Direct drive food processors feature a motor directly connected to the blade assembly, reducing the risk of slippage and ensuring consistent power transfer, which enhances operational safety. Belt drive models incorporate a removable belt that can absorb impact and prevent motor overload, providing an added layer of protection against mechanical failure. Safety mechanisms in both designs aim to prevent accidental startups and ensure secure assembly, but direct drive systems generally offer greater durability and fewer maintenance concerns.

Cost and Affordability Analysis

Direct drive food processors typically come with a higher upfront cost but offer greater durability and efficiency, reducing long-term maintenance expenses. Belt drive models are generally more affordable initially but may incur additional costs due to belt replacements and less efficient performance over time. Evaluating the total cost of ownership, direct drive systems often prove more cost-effective for frequent use despite their higher price point.

User Experience and Ease of Use

Direct drive food processors offer a more efficient power transfer, resulting in smoother operation and less maintenance, enhancing overall user experience. Belt drive models may produce more noise and require occasional belt replacements, potentially interrupting ease of use. Users seeking consistent performance and minimal upkeep often prefer direct drive systems for their reliability and convenience.

Which Drive System Is Best for Your Kitchen Needs?

Direct drive food processors offer greater power and durability by connecting the motor directly to the blade, making them ideal for heavy-duty tasks like kneading dough or processing tough ingredients. Belt drive models provide quieter operation and easier maintenance, suiting users who prioritize noise reduction and occasional, light food preparation. Choosing the best drive system depends on whether your kitchen demands high performance and robustness or quieter, low-maintenance usage.

Direct drive vs belt drive for food processor Infographic

productvia.com

productvia.com