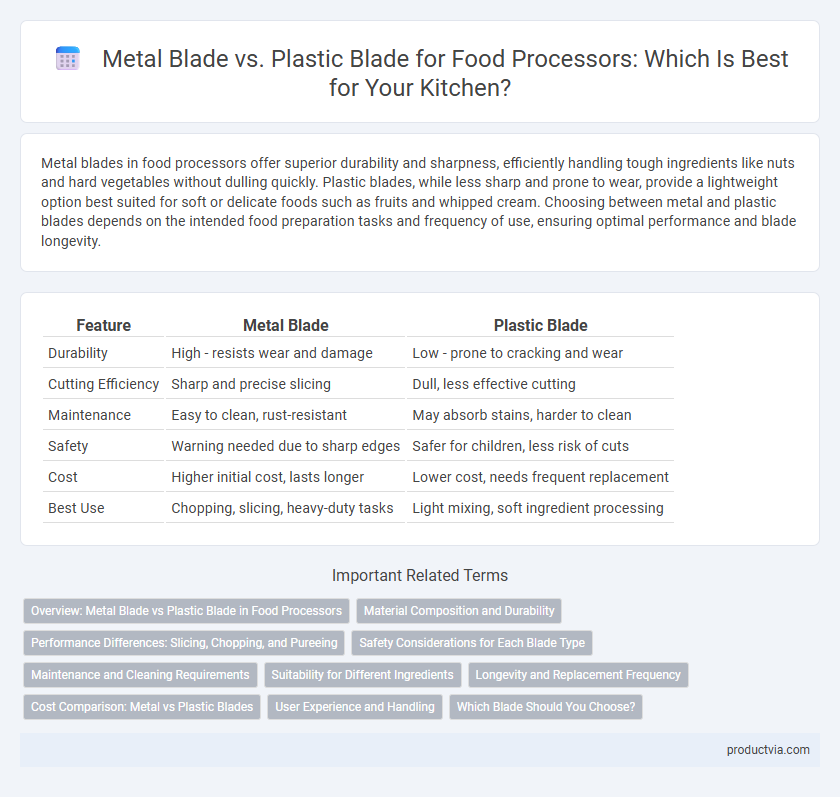

Metal blades in food processors offer superior durability and sharpness, efficiently handling tough ingredients like nuts and hard vegetables without dulling quickly. Plastic blades, while less sharp and prone to wear, provide a lightweight option best suited for soft or delicate foods such as fruits and whipped cream. Choosing between metal and plastic blades depends on the intended food preparation tasks and frequency of use, ensuring optimal performance and blade longevity.

Table of Comparison

| Feature | Metal Blade | Plastic Blade |

|---|---|---|

| Durability | High - resists wear and damage | Low - prone to cracking and wear |

| Cutting Efficiency | Sharp and precise slicing | Dull, less effective cutting |

| Maintenance | Easy to clean, rust-resistant | May absorb stains, harder to clean |

| Safety | Warning needed due to sharp edges | Safer for children, less risk of cuts |

| Cost | Higher initial cost, lasts longer | Lower cost, needs frequent replacement |

| Best Use | Chopping, slicing, heavy-duty tasks | Light mixing, soft ingredient processing |

Overview: Metal Blade vs Plastic Blade in Food Processors

Metal blades in food processors offer superior durability and sharpness, efficiently handling tough ingredients like nuts and raw vegetables with precise cutting and chopping. Plastic blades are lightweight and safer for delicate tasks, ideal for softer fruits and gentle mixing without dulling quickly or causing damage to non-stick bowls. Choosing between metal and plastic blades depends on the processing needs, with metal blades providing robust performance and plastic blades offering versatility and safety for specific culinary applications.

Material Composition and Durability

Metal blades in food processors are typically made from stainless steel, offering superior sharpness and long-lasting durability compared to plastic blades. Plastic blades, constructed from high-density polymers, are less prone to corrosion but generally lack the strength to handle tough ingredients, leading to quicker wear and reduced performance. The material composition of metal blades makes them more resistant to bending and dulling, ensuring consistent cutting efficiency over extended use.

Performance Differences: Slicing, Chopping, and Pureeing

Metal blades in food processors deliver superior slicing, chopping, and pureeing performance due to their sharpness and durability, efficiently handling tough ingredients like nuts and hard vegetables. Plastic blades tend to dull quickly and may struggle with consistent cuts, making them less effective for precise slicing or fine purees. For tasks requiring high precision and speed, metal blades ensure better texture and uniformity in food preparation.

Safety Considerations for Each Blade Type

Metal blades in food processors offer superior durability and cutting efficiency but require cautious handling due to their sharpness and potential for causing injury. Plastic blades provide a safer alternative for less intense chopping tasks, reducing the risk of cuts and making them suitable for children or users with limited kitchen experience. Both blade types should be carefully maintained and stored to avoid accidents and ensure optimal performance.

Maintenance and Cleaning Requirements

Metal blades in food processors require minimal maintenance due to their durability and resistance to corrosion, allowing for easy cleaning by hand or in the dishwasher without risk of damage. Plastic blades often demand more careful handling to prevent wear and may retain food residues, necessitating thorough cleaning to avoid odor buildup and staining. Choosing metal blades enhances longevity and simplifies upkeep, ensuring consistent performance with less frequent replacement.

Suitability for Different Ingredients

Metal blades in food processors offer superior durability and sharpness, making them ideal for chopping hard ingredients like nuts, ice, and dense vegetables. Plastic blades suit softer ingredients such as fruits, herbs, and cooked vegetables, providing gentle processing without bruising delicate textures. Choosing the right blade depends on the ingredient hardness and desired consistency for optimal food preparation results.

Longevity and Replacement Frequency

Metal blades in food processors offer superior longevity due to their resistance to wear, corrosion, and dulling, often lasting several years without needing replacement. Plastic blades tend to degrade faster, especially under heavy use or exposure to sharp ingredients, leading to more frequent replacements. Choosing a metal blade can reduce long-term maintenance costs and ensure consistent performance over time.

Cost Comparison: Metal vs Plastic Blades

Metal blades for food processors typically cost more upfront, ranging from $15 to $50, due to their durability and superior cutting performance. Plastic blades are generally cheaper, priced between $5 and $20, but may wear out faster and require more frequent replacement. Choosing metal blades offers better long-term value despite higher initial investment, while plastic blades appeal to budget-conscious consumers prioritizing low immediate cost.

User Experience and Handling

Metal blades in food processors provide superior sharpness and durability, ensuring precise and efficient chopping, slicing, and dicing, which enhances user experience by reducing effort and processing time. Plastic blades, while generally safer and lighter, tend to dull faster and may struggle with tougher ingredients, leading to more frequent replacements and a less satisfying handling experience. Users prioritizing performance and longevity typically prefer metal blades, whereas those valuing ease of cleaning and safety might opt for plastic options.

Which Blade Should You Choose?

Metal blades in food processors offer superior durability and sharpness, making them ideal for heavy-duty tasks like chopping nuts, grinding meat, or slicing tough vegetables. Plastic blades are generally more affordable and lightweight but lack the cutting precision and longevity of metal blades, suited for light food preparation such as mixing or blending soft ingredients. Choosing between metal and plastic blades depends on the specific food processing needs, frequency of use, and the types of ingredients processed.

Metal blade vs Plastic blade for food processor Infographic

productvia.com

productvia.com