Metal spindles in food processors offer superior durability compared to plastic spindles, resisting wear and tear from frequent use and heavy-duty tasks. Plastic spindles tend to degrade faster under pressure, potentially leading to breakage or malfunction over time. Choosing a food processor with a metal spindle ensures longer lifespan and reliable performance during intensive food preparation.

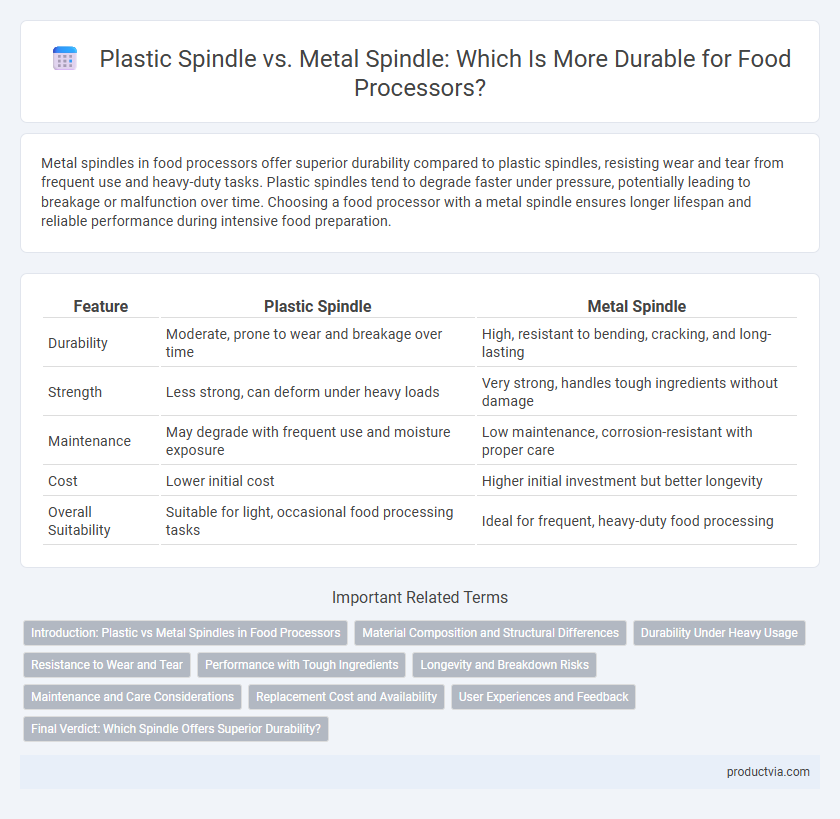

Table of Comparison

| Feature | Plastic Spindle | Metal Spindle |

|---|---|---|

| Durability | Moderate, prone to wear and breakage over time | High, resistant to bending, cracking, and long-lasting |

| Strength | Less strong, can deform under heavy loads | Very strong, handles tough ingredients without damage |

| Maintenance | May degrade with frequent use and moisture exposure | Low maintenance, corrosion-resistant with proper care |

| Cost | Lower initial cost | Higher initial investment but better longevity |

| Overall Suitability | Suitable for light, occasional food processing tasks | Ideal for frequent, heavy-duty food processing |

Introduction: Plastic vs Metal Spindles in Food Processors

Metal spindles in food processors offer superior durability and resistance to wear compared to plastic spindles, which are more prone to cracking and deformation over time. The strength of metal spindles ensures consistent performance under heavy use and high torque conditions, extending the lifespan of the appliance. Plastic spindles, while lighter and less costly, generally serve best in light-duty tasks where long-term durability is less critical.

Material Composition and Structural Differences

Plastic spindles in food processors typically consist of high-impact polymers such as nylon or reinforced polypropylene, offering lightweight performance but lower resistance to wear and deformation under heavy use. Metal spindles, often made from stainless steel or hardened alloys, provide superior durability through enhanced tensile strength, corrosion resistance, and structural rigidity, enabling better load distribution and longer lifespan. The fundamental structural difference lies in metal spindles' ability to maintain shape and resist stress fractures during extended operation, whereas plastic spindles may experience faster degradation and potential failure under repeated mechanical strain.

Durability Under Heavy Usage

Metal spindles in food processors offer superior durability under heavy usage, resisting wear and bending even with prolonged operation and tough ingredients. Plastic spindles may degrade or crack over time when exposed to continuous high pressure and friction, reducing the appliance's lifespan. Choosing a food processor with a metal spindle ensures long-term reliability and consistent performance for frequent or intensive cooking tasks.

Resistance to Wear and Tear

Metal spindles in food processors offer superior resistance to wear and tear compared to plastic spindles, enhancing long-term durability during heavy use. Plastic spindles tend to degrade faster under constant friction and pressure, leading to potential breakage or malfunction. Choosing metal spindles reduces maintenance frequency and ensures consistent performance in demanding kitchen tasks.

Performance with Tough Ingredients

Metal spindles in food processors offer superior durability and performance when handling tough ingredients like nuts, fibrous vegetables, and dense doughs. Plastic spindles may wear down or crack under heavy use, reducing efficiency and potentially causing malfunctions. Choosing a metal spindle ensures consistent power transmission and longer lifespan for high-demand food processing tasks.

Longevity and Breakdown Risks

Metal spindles in food processors offer superior durability and longevity compared to plastic spindles, which are more prone to wear and breakage over time. The increased strength of metal reduces the risk of spindle deformation or cracking during heavy or prolonged use, extending the overall lifespan of the appliance. Plastic spindles may degrade faster due to mechanical stress and heat exposure, resulting in higher breakdown risks and more frequent replacements.

Maintenance and Care Considerations

Metal spindles in food processors offer superior durability and require less frequent replacement compared to plastic spindles, which are prone to cracking under stress. Maintenance for metal spindles typically involves regular cleaning and occasional lubrication to prevent rust, while plastic spindles demand careful handling to avoid wear and are more susceptible to damage from high temperatures. Choosing a metal spindle reduces long-term repair costs and ensures consistent performance during heavy or prolonged use.

Replacement Cost and Availability

Metal spindles in food processors offer superior durability compared to plastic spindles, significantly reducing the frequency of replacements. Plastic spindles tend to wear out faster and are often less available as replacement parts, leading to higher long-term costs and limited sourcing options. Investing in a metal spindle ensures a longer lifespan and easier access to replacement components, minimizing downtime and repair expenses.

User Experiences and Feedback

Metal spindles in food processors consistently receive positive user feedback for superior durability and long-term reliability, with many users noting resistance to bending and wear even under heavy use. Plastic spindles often attract criticism from experienced users due to their tendency to crack or degrade over time, especially when processing tough ingredients. Consumer reviews highlight that metal spindle models maintain performance and safety better, contributing to higher overall satisfaction and fewer repairs.

Final Verdict: Which Spindle Offers Superior Durability?

Metal spindles outperform plastic spindles in durability due to their resistance to wear, heat, and pressure during extended food processing tasks. Plastic spindles are prone to cracking and warping under heavy use, leading to a shorter lifespan and potential malfunction. The final verdict favors metal spindles as the superior choice for long-lasting, reliable performance in food processors.

Plastic spindle vs Metal spindle for durability Infographic

productvia.com

productvia.com