A sealed bowl in a food processor ensures no spills or leaks when handling liquids, making it ideal for soups, sauces, and dressings. A non-sealed bowl may allow liquids to escape, leading to messes and inconsistent texture in recipes requiring precise liquid control. Choosing a sealed bowl guarantees better containment, enhancing safety and cleanliness during food preparation.

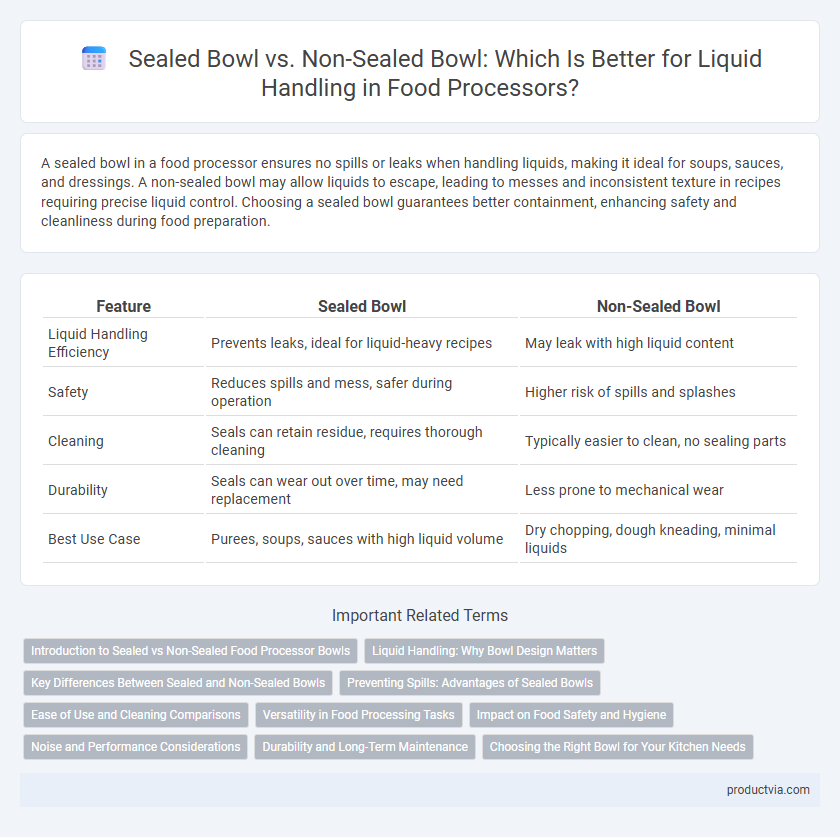

Table of Comparison

| Feature | Sealed Bowl | Non-Sealed Bowl |

|---|---|---|

| Liquid Handling Efficiency | Prevents leaks, ideal for liquid-heavy recipes | May leak with high liquid content |

| Safety | Reduces spills and mess, safer during operation | Higher risk of spills and splashes |

| Cleaning | Seals can retain residue, requires thorough cleaning | Typically easier to clean, no sealing parts |

| Durability | Seals can wear out over time, may need replacement | Less prone to mechanical wear |

| Best Use Case | Purees, soups, sauces with high liquid volume | Dry chopping, dough kneading, minimal liquids |

Introduction to Sealed vs Non-Sealed Food Processor Bowls

Sealed food processor bowls provide a leak-proof design that effectively contains liquids and prevents spills during processing, making them ideal for soups, sauces, and dressings. Non-sealed bowls may allow liquids to escape through gaps or seams, which can lead to messes and reduced efficiency when handling high-moisture ingredients. Choosing a sealed bowl enhances safety and cleanliness, ensuring consistent mixing and blending without compromising kitchen hygiene.

Liquid Handling: Why Bowl Design Matters

Sealed bowls in food processors prevent liquid leaks and ensure efficient handling of soups, sauces, and dressings by maintaining a tight seal during operation. Non-sealed bowls often allow liquid to escape, causing messes and reduced processing efficiency when dealing with high-moisture ingredients. Choosing a sealed bowl design enhances user experience by enabling smoother blending and mixing of liquids without spillage or loss of contents.

Key Differences Between Sealed and Non-Sealed Bowls

Sealed bowls in food processors provide airtight containment, preventing leaks and spills when processing liquids, making them ideal for soups, sauces, and dressings. Non-sealed bowls lack this airtight feature, allowing for easier mixing of dry ingredients but posing a higher risk of liquid spillage during high-speed blending. The key difference lies in liquid handling efficiency: sealed bowls ensure mess-free operation and preserve consistency, while non-sealed bowls prioritize versatility with dry processing.

Preventing Spills: Advantages of Sealed Bowls

Sealed bowls in food processors provide a watertight barrier that prevents liquid spills during blending or mixing, ensuring a cleaner countertop and reduced risk of mess. The airtight seal maintains pressure within the bowl, allowing for efficient liquid handling without leaks, even at high speeds. This feature is especially advantageous when processing soups, sauces, or emulsions, where non-sealed bowls often fail to contain liquids securely.

Ease of Use and Cleaning Comparisons

Sealed bowls in food processors prevent leaks and spills during liquid handling, enhancing ease of use by maintaining a mess-free environment. Non-sealed bowls may allow liquids to seep through gaps, requiring more careful handling and cleanup. Cleaning sealed bowls is generally simpler due to fewer crevices where liquids can get trapped, whereas non-sealed bowls often demand extra attention to avoid residue buildup.

Versatility in Food Processing Tasks

Sealed bowls prevent liquid leaks, enhancing the versatility of food processors for handling soups, sauces, and wet batter without mess. Non-sealed bowls, while easier to clean and often lighter, may limit use with high-liquid recipes due to potential spills. Choosing between sealed and non-sealed bowls impacts the ability to seamlessly transition between dry and wet food processing tasks.

Impact on Food Safety and Hygiene

Sealed bowls in food processors prevent leaks and contamination, ensuring liquids remain contained and reducing the risk of cross-contamination during food preparation. Non-sealed bowls may allow liquids to escape, increasing chances of spillage and bacterial growth on the motor base or countertop, compromising hygiene. Maintaining a sealed system enhances food safety by minimizing exposure to harmful pathogens and facilitating easier cleaning.

Noise and Performance Considerations

Sealed bowls in food processors significantly reduce noise by minimizing liquid splashes and vibrations, enhancing user comfort during operation. Performance-wise, sealed bowls prevent liquid leaks and maintain consistent pressure, leading to smoother blending and processing of wet ingredients. Non-sealed bowls may produce more noise and risk spills but can offer easier cleaning and assembly for dry food tasks.

Durability and Long-Term Maintenance

A sealed bowl in food processors ensures leak-proof liquid handling, preventing spills and reducing wear on motor components, which enhances durability and minimizes maintenance needs over time. Non-sealed bowls often allow liquids to seep into mechanical parts, increasing the risk of damage and requiring more frequent repairs or replacements. Choosing a sealed bowl model supports long-term reliability and consistent performance.

Choosing the Right Bowl for Your Kitchen Needs

A sealed bowl in a food processor ensures leak-proof handling of liquids, preventing spills and messes during blending or pureeing tasks. Non-sealed bowls may be suitable for dry ingredient processing but risk leakage when dealing with soups, sauces, or other liquids. Selecting the right bowl depends on kitchen needs, prioritizing sealed options for versatile liquid handling and non-sealed bowls for primarily dry food preparation.

Sealed bowl vs Non-sealed bowl for liquid handling Infographic

productvia.com

productvia.com