Direct steam reheating exposes food to steam immediately, preserving moisture and accelerating the heating process without drying out the pet's meal. Indirect steam uses a barrier, such as a tray or container, preventing direct contact with steam while evenly distributing heat to avoid hot spots. Choosing between direct and indirect steam depends on the food texture and the need to maintain nutritional value during reheating.

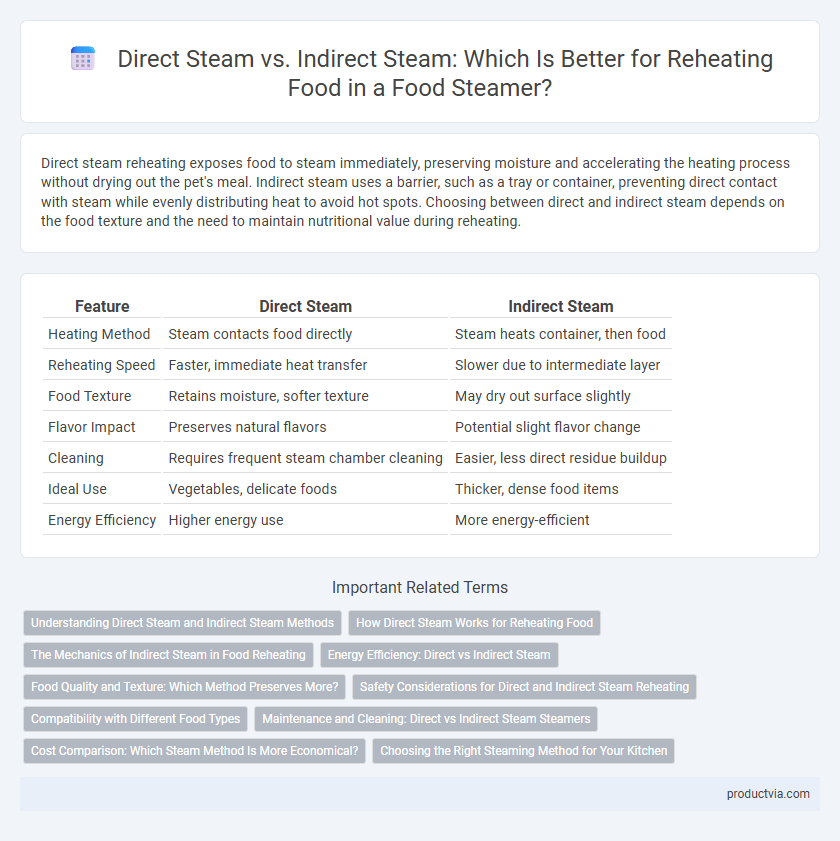

Table of Comparison

| Feature | Direct Steam | Indirect Steam |

|---|---|---|

| Heating Method | Steam contacts food directly | Steam heats container, then food |

| Reheating Speed | Faster, immediate heat transfer | Slower due to intermediate layer |

| Food Texture | Retains moisture, softer texture | May dry out surface slightly |

| Flavor Impact | Preserves natural flavors | Potential slight flavor change |

| Cleaning | Requires frequent steam chamber cleaning | Easier, less direct residue buildup |

| Ideal Use | Vegetables, delicate foods | Thicker, dense food items |

| Energy Efficiency | Higher energy use | More energy-efficient |

Understanding Direct Steam and Indirect Steam Methods

Direct steam reheating involves exposing food directly to steam, which ensures rapid and even heat distribution, preserving moisture and texture. Indirect steam reheating uses steam to heat a separate surface or container, reducing the risk of over-saturation and preventing food from becoming soggy. Understanding these methods helps optimize reheating based on food type, moisture content, and desired texture.

How Direct Steam Works for Reheating Food

Direct steam reheating works by exposing food directly to high-temperature steam, which rapidly transfers heat through condensation on the food's surface. This method efficiently preserves moisture and texture, preventing drying or overheating, making it ideal for delicate or easily overcooked dishes. Steam's high latent heat ensures uniform reheating, minimizing nutrient loss while maintaining food quality.

The Mechanics of Indirect Steam in Food Reheating

Indirect steam reheating utilizes a water-filled container to generate steam, preventing direct contact between steam and food which preserves texture and flavor. The steam heats the container, which then transfers warmth evenly to the food through conduction, reducing the risk of overheating and moisture loss. This method is ideal for delicate foods requiring gentle, uniform reheating without sogginess or burns.

Energy Efficiency: Direct vs Indirect Steam

Direct steam reheating delivers heat by injecting steam straight onto the food, resulting in faster energy transfer and reduced heat loss, which enhances overall energy efficiency. Indirect steam heats through a barrier, such as a pan or tray, causing slower heat transfer and higher energy consumption due to additional thermal resistance. Choosing direct steam methods typically lowers energy usage in commercial and home food steaming applications by minimizing heat dissipation.

Food Quality and Texture: Which Method Preserves More?

Direct steam reheating exposes food directly to steam, maintaining moisture and preserving natural texture, making it ideal for delicate items like vegetables and seafood. Indirect steam reheating uses a steam-heated surface or water bath, which provides gentler heat but may cause slight drying or texture change in some foods over time. Overall, direct steam better preserves food quality and texture by preventing dehydration and uneven heating during reheating.

Safety Considerations for Direct and Indirect Steam Reheating

Direct steam reheating involves placing food directly in contact with steam, which ensures rapid and even heating but requires careful monitoring to prevent overexposure that can cause burns or uneven temperature distribution. Indirect steam reheating uses a steam jacket or water bath, minimizing the risk of contamination and reducing the chance of food drying out or developing hot spots, thus enhancing food safety during reheating. Proper maintenance of equipment and adherence to temperature controls are critical safety measures for both direct and indirect steam methods to prevent pathogen growth and ensure food is reheated to safe consumption temperatures.

Compatibility with Different Food Types

Direct steam reheating efficiently penetrates dense foods like vegetables and meats, preserving moisture and texture without overcooking. Indirect steam suits delicate items such as custards or bread, providing gentle heat that reduces the risk of sogginess or uneven warming. Selecting between direct and indirect steam depends on the specific food's texture and moisture sensitivity to ensure optimal reheating results.

Maintenance and Cleaning: Direct vs Indirect Steam Steamers

Direct steam steamers require frequent descaling and careful cleaning of exposed steam chambers to prevent mineral buildup and ensure food safety, increasing maintenance efforts. Indirect steam steamers feature sealed steam generators that reduce mineral deposits in cooking areas, simplifying cleaning and enhancing durability. Choosing between direct and indirect steam impacts long-term hygiene and maintenance routines for efficient food reheating.

Cost Comparison: Which Steam Method Is More Economical?

Direct steam reheating typically incurs higher operational costs due to increased water and energy consumption, making it less economical for frequent use. Indirect steam methods, which utilize steam heat without direct contact, generally offer better energy efficiency and lower maintenance expenses, resulting in more cost-effective long-term operation. Businesses aiming to balance quality and cost often prefer indirect steaming to minimize resource expenditure while preserving food texture.

Choosing the Right Steaming Method for Your Kitchen

Direct steam reheating uses steam that comes into direct contact with the food, ensuring faster heat transfer and preserving moisture and texture. Indirect steam involves heating food placed in a container or tray above boiling water, offering gentler reheating that reduces the risk of overcooking delicate items. Choosing the right steaming method depends on the type of food, desired texture, and reheating speed, with direct steam ideal for dense vegetables and meats, while indirect steam suits delicate dishes like fish or custards.

Direct steam vs Indirect steam for reheating food Infographic

productvia.com

productvia.com