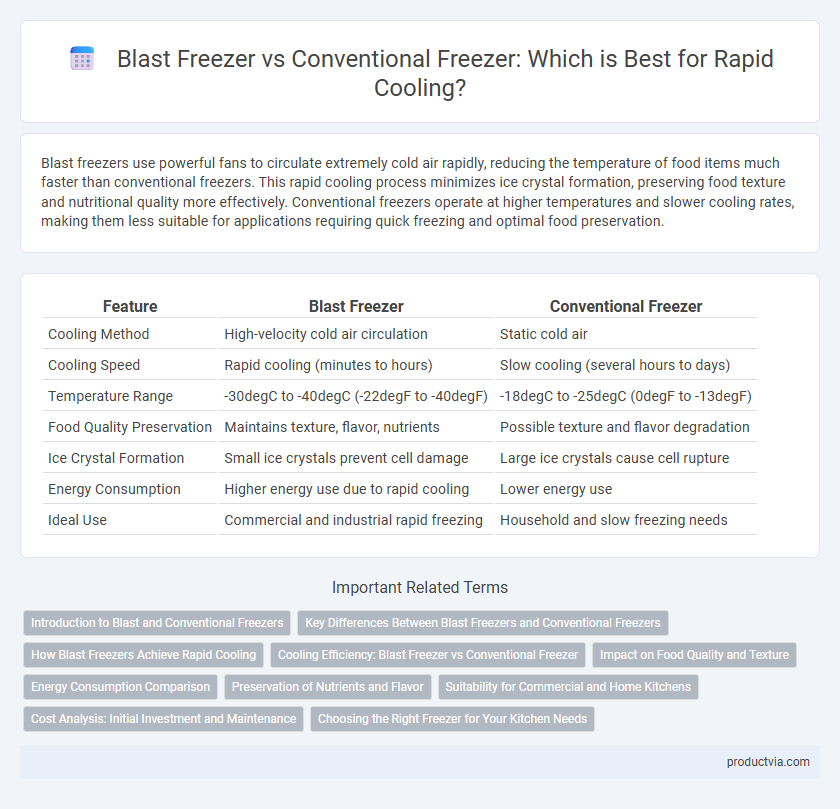

Blast freezers use powerful fans to circulate extremely cold air rapidly, reducing the temperature of food items much faster than conventional freezers. This rapid cooling process minimizes ice crystal formation, preserving food texture and nutritional quality more effectively. Conventional freezers operate at higher temperatures and slower cooling rates, making them less suitable for applications requiring quick freezing and optimal food preservation.

Table of Comparison

| Feature | Blast Freezer | Conventional Freezer |

|---|---|---|

| Cooling Method | High-velocity cold air circulation | Static cold air |

| Cooling Speed | Rapid cooling (minutes to hours) | Slow cooling (several hours to days) |

| Temperature Range | -30degC to -40degC (-22degF to -40degF) | -18degC to -25degC (0degF to -13degF) |

| Food Quality Preservation | Maintains texture, flavor, nutrients | Possible texture and flavor degradation |

| Ice Crystal Formation | Small ice crystals prevent cell damage | Large ice crystals cause cell rupture |

| Energy Consumption | Higher energy use due to rapid cooling | Lower energy use |

| Ideal Use | Commercial and industrial rapid freezing | Household and slow freezing needs |

Introduction to Blast and Conventional Freezers

Blast freezers utilize powerful fans to circulate extremely cold air rapidly, enabling food to freeze quickly and preserve texture, flavor, and nutritional value. Conventional freezers rely on slower cooling methods, often leading to larger ice crystals that can degrade food quality over time. Rapid cooling in blast freezers minimizes cellular damage, making them essential for food industries requiring high-quality frozen products.

Key Differences Between Blast Freezers and Conventional Freezers

Blast freezers rapidly reduce temperatures to -30degF or lower within hours by circulating intense cold air, preserving food quality and preventing bacterial growth. Conventional freezers cool slower, maintaining temperatures around 0degF, which may allow ice crystals to form and degrade texture over time. The key difference lies in the speed and uniformity of cooling, with blast freezers offering superior preservation for high-value perishable items.

How Blast Freezers Achieve Rapid Cooling

Blast freezers achieve rapid cooling through powerful fans that circulate extremely cold air at speeds up to 3 meters per second, enabling uniform and swift temperature reduction. The temperature inside blast freezers typically ranges from -30degC to -40degC, significantly lower than conventional freezers, which usually maintain around -18degC. This combination of intense cold and high-velocity airflow minimizes ice crystal formation, preserving food quality and safety during rapid freezing.

Cooling Efficiency: Blast Freezer vs Conventional Freezer

Blast freezers achieve rapid cooling by circulating extremely cold air at high velocity, significantly reducing the temperature of food products within minutes and minimizing ice crystal formation to preserve texture and flavor. Conventional freezers use slower cooling processes, relying on static or low-velocity cold air, which leads to longer freezing times and increased risk of moisture loss and structural damage in food. The superior cooling efficiency of blast freezers enhances food safety and quality by rapidly lowering the product temperature below critical bacterial growth thresholds.

Impact on Food Quality and Texture

Blast freezers use powerful, high-velocity air circulation to rapidly lower food temperature, minimizing ice crystal formation and preserving cellular structure, which significantly enhances food quality and texture. Conventional freezers cool food more slowly, causing larger ice crystals that can damage cell walls, leading to compromised texture and moisture loss upon thawing. Rapid cooling in blast freezers retains freshness, flavor, and nutritional value, making them ideal for maintaining superior food quality compared to conventional freezers.

Energy Consumption Comparison

Blast freezers use high-velocity cold air circulation to rapidly reduce food temperature, resulting in shorter cooling cycles compared to conventional freezers that rely on slower refrigeration processes. This rapid cooling significantly decreases energy consumption per cooling session by reducing compressor run times, despite the higher initial power demand. Studies show blast freezers can achieve up to 30% energy savings in industrial applications due to optimized airflow and reduced thermal load duration.

Preservation of Nutrients and Flavor

Blast freezers utilize ultra-low temperatures and high-velocity air circulation to rapidly freeze food, preserving nutrients and flavor more effectively than conventional freezers, which cool at a slower rate. Rapid freezing minimizes ice crystal formation, reducing cellular damage and maintaining the food's original texture and taste. This technology is especially beneficial in preserving the quality of fruits, vegetables, and meats by locking in freshness shortly after harvesting or processing.

Suitability for Commercial and Home Kitchens

Blast freezers rapidly reduce food temperature by circulating extremely cold air, making them ideal for commercial kitchens requiring quick cooling to preserve freshness and comply with safety standards. Conventional freezers offer slower cooling rates suitable for home kitchens where rapid freezing is less critical and energy consumption needs to be minimized. Commercial kitchens benefit from blast freezers' efficiency in maintaining food quality during high-volume operations, whereas conventional freezers prioritize cost-effectiveness and ease of use for household needs.

Cost Analysis: Initial Investment and Maintenance

Blast freezers require a higher initial investment compared to conventional freezers due to advanced refrigeration technology and enhanced airflow systems. Maintenance costs for blast freezers tend to be elevated, driven by specialized components and the need for frequent servicing to ensure optimal rapid cooling performance. Conventional freezers offer lower upfront and maintenance expenses but lack the efficiency and speed of blast freezing in preserving product quality.

Choosing the Right Freezer for Your Kitchen Needs

Blast freezers utilize high-velocity cold air to rapidly reduce food temperature, preserving texture and nutritional value more effectively than conventional freezers. Conventional freezers operate at slower cooling rates, which may lead to larger ice crystals and potential quality degradation in frozen food. Selecting the right freezer depends on kitchen throughput, intended food types, and prioritizing rapid cooling to maintain freshness and extend shelf life in commercial settings.

Blast Freezer vs Conventional Freezer for Rapid Cooling Infographic

productvia.com

productvia.com