Inverter compressors in freezers adjust their speed based on cooling demand, resulting in less wear and tear compared to conventional compressors that operate at a constant speed. This variable-speed operation enhances energy efficiency and reduces mechanical stress, significantly extending the freezer's lifespan. Choosing an inverter compressor ensures quieter performance and longer durability, making it a superior option for freezer longevity.

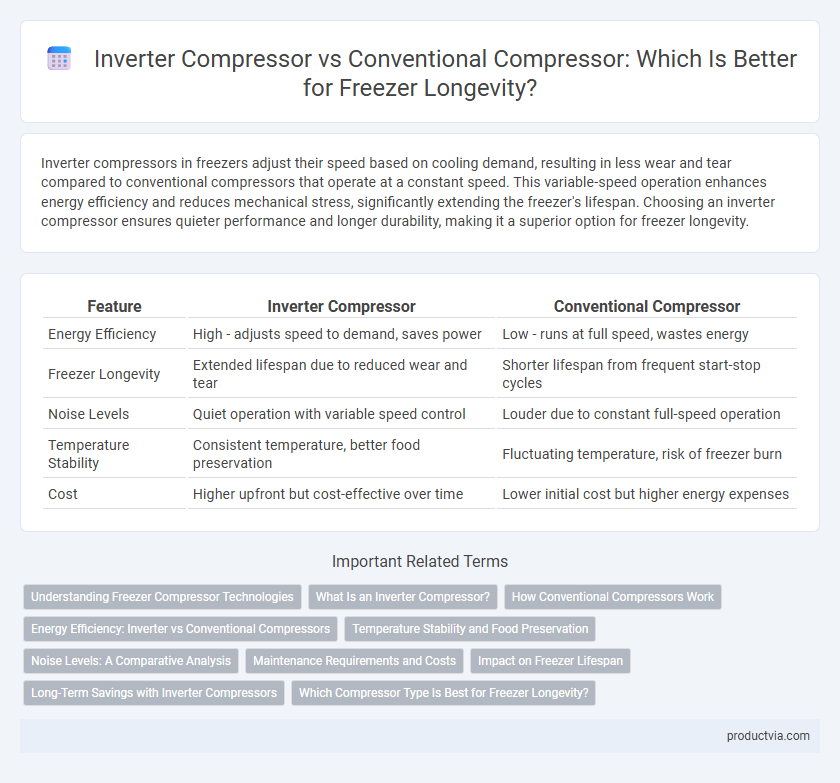

Table of Comparison

| Feature | Inverter Compressor | Conventional Compressor |

|---|---|---|

| Energy Efficiency | High - adjusts speed to demand, saves power | Low - runs at full speed, wastes energy |

| Freezer Longevity | Extended lifespan due to reduced wear and tear | Shorter lifespan from frequent start-stop cycles |

| Noise Levels | Quiet operation with variable speed control | Louder due to constant full-speed operation |

| Temperature Stability | Consistent temperature, better food preservation | Fluctuating temperature, risk of freezer burn |

| Cost | Higher upfront but cost-effective over time | Lower initial cost but higher energy expenses |

Understanding Freezer Compressor Technologies

Inverter compressors adjust their speed to match cooling demands, significantly reducing energy consumption and wear compared to conventional compressors that operate at a fixed speed. This variable-speed technology enhances freezer longevity by maintaining consistent temperatures and minimizing mechanical stress on components. Understanding these compressor technologies helps consumers choose freezers with improved durability and energy efficiency.

What Is an Inverter Compressor?

An inverter compressor in freezers adjusts its speed based on cooling demand, resulting in more efficient and consistent temperature control compared to conventional compressors that operate at fixed speeds. This variable speed technology reduces wear and tear, extending the lifespan of the freezer by minimizing the frequency of start-stop cycles. Inverter compressors also consume less energy, improving the overall durability and cost-effectiveness of the freezer.

How Conventional Compressors Work

Conventional compressors operate using a fixed-speed motor that cycles on and off to maintain the desired freezer temperature, causing frequent start-stop operations. This constant cycling leads to increased wear and tear on compressor components, resulting in reduced longevity and higher energy consumption. In contrast, the mechanical stress from these repeated cycles often shortens the lifespan of conventional compressors compared to variable-speed inverter compressors.

Energy Efficiency: Inverter vs Conventional Compressors

Inverter compressors in freezers adjust their speed based on cooling demand, significantly enhancing energy efficiency by reducing power consumption during stable temperature periods. Conventional compressors operate at a fixed speed, leading to higher energy usage and more wear due to frequent start-stop cycles. Studies show inverter compressors can decrease electricity consumption by up to 30%, extending freezer longevity through smoother operation and reduced mechanical stress.

Temperature Stability and Food Preservation

Inverter compressors maintain consistent temperature stability by adjusting the cooling capacity based on the freezer's internal temperature fluctuations, significantly enhancing food preservation and extending freezer longevity. Conventional compressors operate at a fixed speed, causing temperature swings that can lead to freezer burn and quicker food spoilage. Optimizing freezer performance with an inverter compressor reduces mechanical wear and energy consumption, ensuring longer operational life and superior preservation conditions.

Noise Levels: A Comparative Analysis

Inverter compressors for freezers operate at variable speeds, significantly reducing noise levels compared to conventional compressors that cycle on and off at full power. This continuous, efficient operation minimizes vibration and mechanical stress, leading to quieter performance and enhanced longevity of the freezer. Studies show inverter compressors can lower noise by up to 30-40 decibels, providing a more silent and durable cooling solution over conventional models.

Maintenance Requirements and Costs

Inverter compressors in freezers adjust their speed to maintain consistent temperature, resulting in reduced wear and lower maintenance costs compared to conventional compressors that operate at fixed speeds with frequent on-off cycles. Conventional compressors typically experience higher mechanical stress and energy consumption, leading to more frequent repairs and increased overall maintenance expenses. Investing in an inverter compressor freezer enhances longevity through improved efficiency and decreased likelihood of component failure.

Impact on Freezer Lifespan

Inverter compressors in freezers adjust their speed based on cooling demand, reducing wear and tear compared to the constant operation of conventional compressors. This variable speed technology minimizes temperature fluctuations and mechanical stress, significantly extending the freezer's lifespan. Studies show that freezers with inverter compressors typically last 20-30% longer than those with traditional compressors due to optimized energy efficiency and reduced component strain.

Long-Term Savings with Inverter Compressors

Inverter compressors in freezers adapt their speed to cooling demands, reducing energy consumption and mechanical wear, which significantly extends appliance lifespan. Conventional compressors operate at fixed speeds, causing frequent start-stop cycles that increase electricity bills and maintenance costs over time. Investing in an inverter compressor freezer ensures long-term savings by lowering energy expenses and minimizing costly repairs.

Which Compressor Type Is Best for Freezer Longevity?

Inverter compressors adjust cooling speed based on temperature needs, reducing wear and energy consumption, thereby extending freezer longevity compared to conventional compressors that operate at a fixed speed. Studies show inverter compressors can increase freezer lifespan by maintaining consistent temperatures and decreasing mechanical stress. For optimal freezer durability, selecting a model with an inverter compressor is the best choice.

Inverter Compressor vs Conventional Compressor for Freezer Longevity Infographic

productvia.com

productvia.com