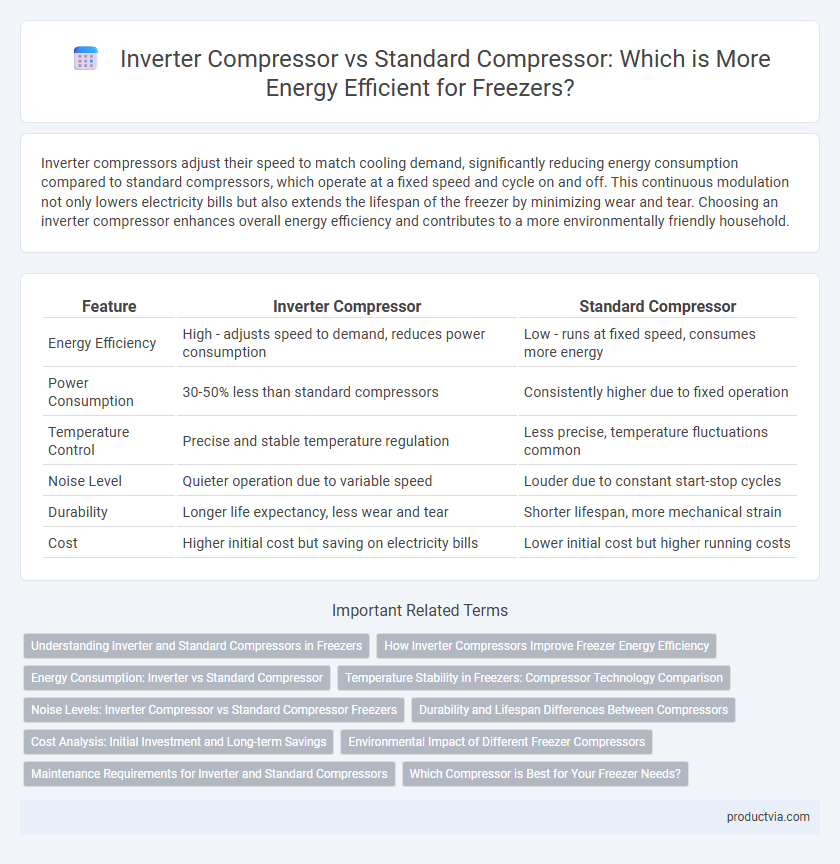

Inverter compressors adjust their speed to match cooling demand, significantly reducing energy consumption compared to standard compressors, which operate at a fixed speed and cycle on and off. This continuous modulation not only lowers electricity bills but also extends the lifespan of the freezer by minimizing wear and tear. Choosing an inverter compressor enhances overall energy efficiency and contributes to a more environmentally friendly household.

Table of Comparison

| Feature | Inverter Compressor | Standard Compressor |

|---|---|---|

| Energy Efficiency | High - adjusts speed to demand, reduces power consumption | Low - runs at fixed speed, consumes more energy |

| Power Consumption | 30-50% less than standard compressors | Consistently higher due to fixed operation |

| Temperature Control | Precise and stable temperature regulation | Less precise, temperature fluctuations common |

| Noise Level | Quieter operation due to variable speed | Louder due to constant start-stop cycles |

| Durability | Longer life expectancy, less wear and tear | Shorter lifespan, more mechanical strain |

| Cost | Higher initial cost but saving on electricity bills | Lower initial cost but higher running costs |

Understanding Inverter and Standard Compressors in Freezers

Inverter compressors in freezers adjust their speed based on cooling demand, significantly reducing energy consumption compared to standard compressors that operate at a fixed speed and cycle on and off. Understanding the operational difference reveals that inverter technology maintains more consistent temperatures, improving energy efficiency and prolonging compressor lifespan. Data shows freezers with inverter compressors can reduce energy usage by up to 30%, making them a cost-effective choice for long-term use.

How Inverter Compressors Improve Freezer Energy Efficiency

Inverter compressors optimize freezer energy efficiency by continuously adjusting their speed to meet cooling demands, reducing power consumption compared to standard compressors that operate at fixed speeds. This variable-speed operation minimizes energy wastage during idle periods and maintains a more consistent temperature, leading to improved energy savings. As a result, freezers equipped with inverter compressors can consume up to 30-50% less electricity than those with standard compressors.

Energy Consumption: Inverter vs Standard Compressor

Inverter compressors adjust their speed according to cooling demand, resulting in lower energy consumption compared to standard compressors that operate at a fixed speed. This variable speed technology reduces power usage by maintaining consistent temperatures without frequent on/off cycling, leading to energy savings of up to 30%. Standard compressors consume more electricity due to constant full-speed operation, increasing overall energy costs in freezer applications.

Temperature Stability in Freezers: Compressor Technology Comparison

Inverter compressors maintain precise temperature stability in freezers by continuously adjusting their speed to meet cooling demands, resulting in more consistent internal temperatures compared to standard compressors that operate in fixed cycles. This modulation reduces temperature fluctuations, preserving food quality and extending freezer efficiency. Standard compressors frequently cycle on and off, causing wider temperature variations that can increase energy consumption and potentially compromise stored food safety.

Noise Levels: Inverter Compressor vs Standard Compressor Freezers

Inverter compressors in freezers operate at variable speeds, significantly reducing noise levels compared to standard compressors that run at a constant speed and frequently cycle on and off. This results in quieter performance and less vibration, making inverter compressor freezers ideal for noise-sensitive environments. Energy-efficient inverter models also minimize sound disturbances while maintaining optimal cooling, enhancing overall user comfort.

Durability and Lifespan Differences Between Compressors

Inverter compressors in freezers adjust their speed based on cooling demand, resulting in less wear and tear and a longer lifespan compared to standard compressors that operate at a constant speed. The variable speed of inverter compressors reduces mechanical stress, enhancing durability and minimizing the risk of breakdowns. Standard compressors experience frequent start-stop cycles, which accelerate aging and reduce overall compressor lifespan in freezer units.

Cost Analysis: Initial Investment and Long-term Savings

Inverter compressors typically demand a higher initial investment compared to standard compressors, but their energy-efficient operation results in significant long-term savings on electricity bills. Standard compressors operate at fixed speeds, causing frequent stops and starts that increase energy consumption and maintenance costs. Investing in an inverter compressor can lower overall expenses through reduced power usage and extended appliance lifespan, making it a cost-effective choice despite the upfront price difference.

Environmental Impact of Different Freezer Compressors

Inverter compressors in freezers adjust cooling speed based on demand, significantly reducing energy consumption and lowering carbon emissions compared to standard compressors that operate at fixed speeds. This adaptive technology enhances environmental sustainability by minimizing electricity use and decreasing greenhouse gas output. Choosing freezers with inverter compressors contributes to a smaller carbon footprint and supports energy-efficient appliance goals.

Maintenance Requirements for Inverter and Standard Compressors

Inverter compressors typically require less maintenance than standard compressors due to their variable speed operation, which reduces wear and tear on components. Standard compressors operate at a fixed speed, leading to more frequent start-stop cycles that increase mechanical stress and maintenance needs. Regular inspection of inverter compressors often focuses on software updates and electronic components, whereas standard compressors demand more frequent checks for mechanical parts like relays and motor brushes.

Which Compressor is Best for Your Freezer Needs?

Inverter compressors adjust their speed based on the cooling demand, offering superior energy efficiency and consistent temperature control compared to standard compressors, which operate at a fixed speed. For freezer needs requiring long-term energy savings and quieter operation, inverter compressors are the optimal choice despite a higher upfront cost. Standard compressors may suit budget-conscious users with less frequent freezer use but generally consume more electricity over time.

Inverter Compressor vs Standard Compressor for Energy Efficiency Infographic

productvia.com

productvia.com