Low-speed grinders generate less friction, minimizing heat buildup and preserving the grinder's material and the pet's grooming comfort. High-speed grinders, while faster, produce more heat, increasing the risk of burns or discomfort during extended use on pets. Choosing a low-speed grinder ensures better heat control, enhancing safety and grooming precision.

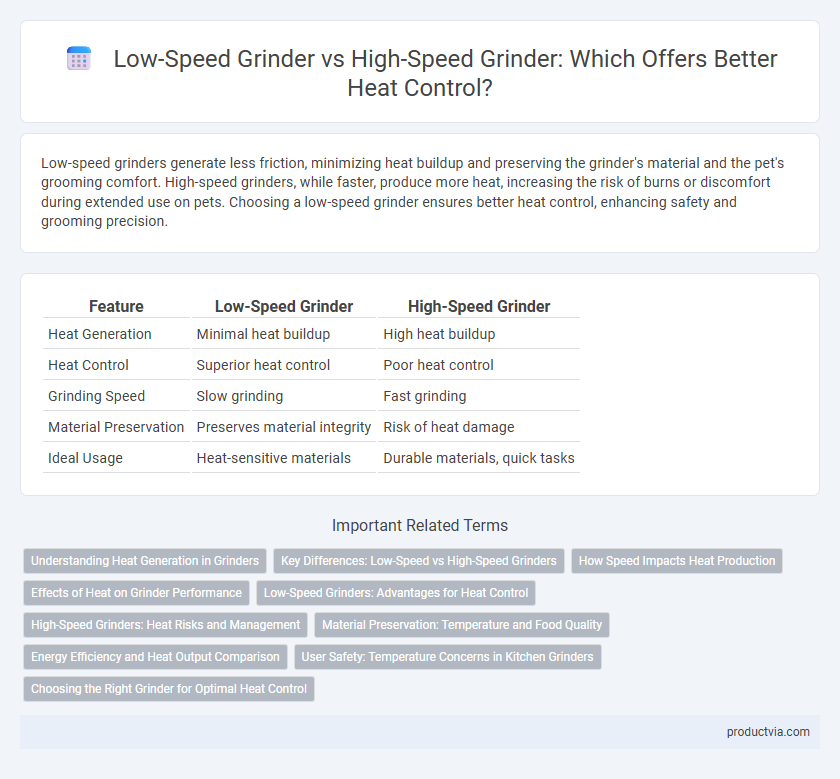

Table of Comparison

| Feature | Low-Speed Grinder | High-Speed Grinder |

|---|---|---|

| Heat Generation | Minimal heat buildup | High heat buildup |

| Heat Control | Superior heat control | Poor heat control |

| Grinding Speed | Slow grinding | Fast grinding |

| Material Preservation | Preserves material integrity | Risk of heat damage |

| Ideal Usage | Heat-sensitive materials | Durable materials, quick tasks |

Understanding Heat Generation in Grinders

Low-speed grinders generate less heat due to slower rotation, preserving the integrity of heat-sensitive materials and preventing flavor degradation in coffee beans. High-speed grinders produce more friction and elevated temperatures, which can lead to burnt aromas and altered taste profiles. Effective heat control is essential for maintaining product quality, making low-speed grinders preferable for applications requiring precision and minimal thermal impact.

Key Differences: Low-Speed vs High-Speed Grinders

Low-speed grinders operate at slower RPMs, producing less heat during grinding, which preserves the aroma and flavor of coffee by minimizing heat-induced degradation. High-speed grinders, while faster and more efficient, generate higher temperatures that can alter bean oils and negatively impact taste quality. The key difference lies in the balance between speed and heat control, with low-speed grinders preferred for delicate heat-sensitive beans.

How Speed Impacts Heat Production

Low-speed grinders operate at slower RPMs, significantly reducing heat generation during grinding, which preserves material integrity and prevents overheating. High-speed grinders, spinning at thousands of RPMs, produce more friction and heat, increasing the risk of thermal damage to sensitive materials. Controlling speed is crucial for heat management, ensuring precise grinding without compromising the quality of heat-sensitive components.

Effects of Heat on Grinder Performance

Low-speed grinders generate less heat during operation, preserving the integrity and flavor profile of the material, especially crucial for sensitive herbs and spices. High-speed grinders, while faster, can cause significant heat buildup, leading to potential degradation of essential oils and altered texture. Effective heat control in low-speed grinders enhances performance by minimizing thermal damage and ensuring a consistent grind quality.

Low-Speed Grinders: Advantages for Heat Control

Low-speed grinders operate at reduced RPMs, significantly minimizing heat generation during grinding, which helps preserve the flavor and aroma of coffee beans. These grinders produce less friction, preventing the beans from overheating and maintaining the optimal grind texture essential for quality brewing. The controlled heat environment reduces the risk of burnt or scorched grounds, ensuring a cleaner and more consistent taste profile.

High-Speed Grinders: Heat Risks and Management

High-speed grinders operate at rapid RPMs, causing significant heat generation that can compromise material integrity and tool lifespan. Effective heat management strategies include using coolant systems, intermittent grinding, and selecting appropriate abrasive materials to dissipate heat efficiently. Proper ventilation and monitoring temperature thresholds are essential to prevent overheating and maintain optimal grinding performance.

Material Preservation: Temperature and Food Quality

Low-speed grinders operate at slower RPMs, generating less heat and preserving the natural flavors and nutrients of the food, which minimizes oxidation and maintains texture. High-speed grinders generate more friction and higher temperatures, risking protein denaturation and loss of aroma in sensitive ingredients. Choosing a low-speed grinder is crucial for heat-sensitive materials like herbs, nuts, and meats to ensure superior food quality and material preservation.

Energy Efficiency and Heat Output Comparison

Low-speed grinders operate at slower RPMs, producing less heat and preserving bean integrity through reduced friction, which enhances energy efficiency by minimizing power consumption during grinding. High-speed grinders generate more heat due to rapid blade movement, increasing the risk of flavor degradation and higher energy usage as motors work harder to maintain speed. Comparing both, low-speed grinders offer superior heat control, leading to lower thermal output and better energy conservation in coffee preparation processes.

User Safety: Temperature Concerns in Kitchen Grinders

Low-speed grinders generate less heat due to slower blade rotation, preventing overheating and minimizing the risk of burns during prolonged use. High-speed grinders, while faster, can reach higher temperatures that may compromise user safety by causing hot surfaces or food discoloration. Maintaining lower temperatures in low-speed grinders helps protect kitchen users from potential heat-related injuries and preserves ingredient quality.

Choosing the Right Grinder for Optimal Heat Control

Low-speed grinders operate at slower RPMs, generating less friction and heat, which helps preserve the coffee bean's natural flavors by preventing overheating. High-speed grinders, while faster, tend to produce more heat that can burn the coffee grounds and negatively impact taste and aroma. Choosing a low-speed grinder is optimal for heat control, ensuring consistent grind quality and flavor integrity during coffee preparation.

Low-speed grinder vs High-speed grinder for heat control Infographic

productvia.com

productvia.com