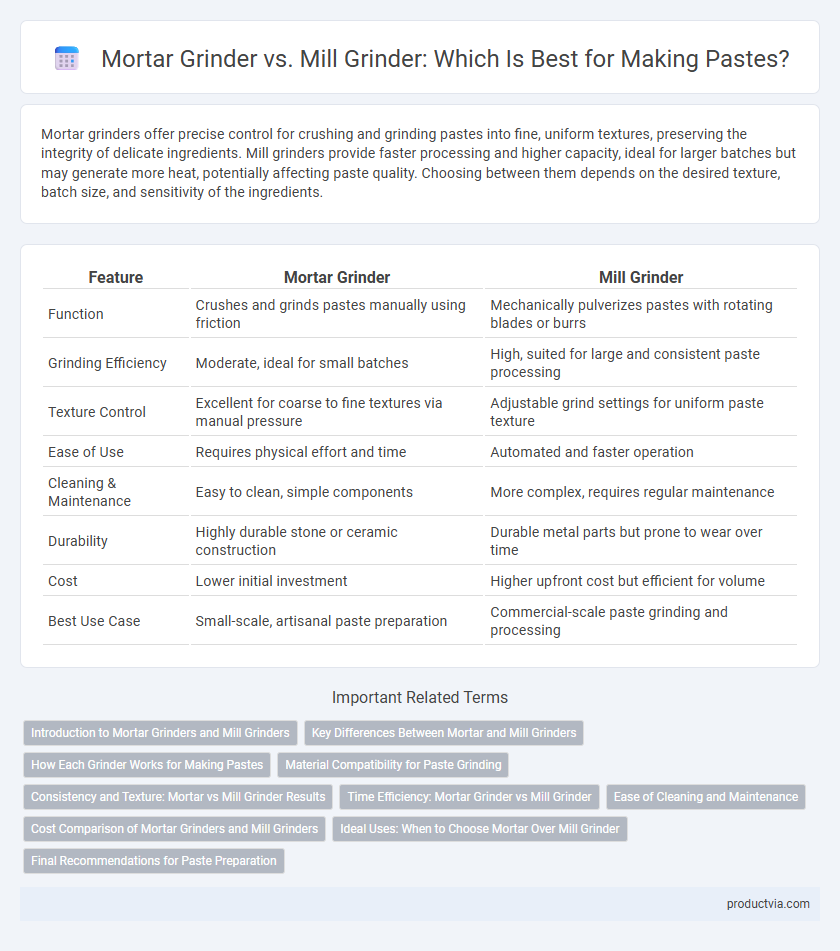

Mortar grinders offer precise control for crushing and grinding pastes into fine, uniform textures, preserving the integrity of delicate ingredients. Mill grinders provide faster processing and higher capacity, ideal for larger batches but may generate more heat, potentially affecting paste quality. Choosing between them depends on the desired texture, batch size, and sensitivity of the ingredients.

Table of Comparison

| Feature | Mortar Grinder | Mill Grinder |

|---|---|---|

| Function | Crushes and grinds pastes manually using friction | Mechanically pulverizes pastes with rotating blades or burrs |

| Grinding Efficiency | Moderate, ideal for small batches | High, suited for large and consistent paste processing |

| Texture Control | Excellent for coarse to fine textures via manual pressure | Adjustable grind settings for uniform paste texture |

| Ease of Use | Requires physical effort and time | Automated and faster operation |

| Cleaning & Maintenance | Easy to clean, simple components | More complex, requires regular maintenance |

| Durability | Highly durable stone or ceramic construction | Durable metal parts but prone to wear over time |

| Cost | Lower initial investment | Higher upfront cost but efficient for volume |

| Best Use Case | Small-scale, artisanal paste preparation | Commercial-scale paste grinding and processing |

Introduction to Mortar Grinders and Mill Grinders

Mortar grinders use a rotating grinding bowl and pestle to finely grind pastes, offering precise control and uniform texture ideal for laboratory and culinary applications. Mill grinders employ rotating blades or burrs to crush and shear materials, providing efficient size reduction suitable for larger batches or coarser grinding of pastes. Both devices optimize paste consistency but differ in mechanism and scale, influencing grind quality and processing speed.

Key Differences Between Mortar and Mill Grinders

Mortar grinders use a manual or motorized pestle rotating against a bowl to crush and grind pastes, providing precise control and suitable for small batches. Mill grinders operate by rotating burrs or blades at high speeds to shear and homogenize ingredients, offering faster processing and higher throughput. Key differences include grinding mechanism, batch size capacity, and texture control, with mortar grinders favoring coarse, controlled crushing and mill grinders excelling in fine, uniform paste production.

How Each Grinder Works for Making Pastes

Mortar grinders crush ingredients by manual or motorized grinding against a rough surface, efficiently breaking down fibers to create smooth, textured pastes. Mill grinders utilize rotating blades or burrs to pulverize ingredients into fine pastes through mechanical shearing and friction. Both methods offer distinct textural outcomes, with mortar grinders providing traditional, coarse pastes and mill grinders producing consistently finer paste textures.

Material Compatibility for Paste Grinding

Mortar grinders excel in handling soft and fibrous materials like herbs and spices for paste grinding, preserving the natural oils and texture due to their gentle grinding mechanism. Mill grinders are better suited for tougher, denser materials such as nuts and seeds, offering consistent particle size through mechanized grinding but may generate more heat, potentially affecting paste quality. Selecting the appropriate grinder depends on the paste's material compatibility, balancing texture preservation and grinding efficiency.

Consistency and Texture: Mortar vs Mill Grinder Results

Mortar grinders offer a coarser texture with less uniform consistency, making them suitable for rough pastes and traditional recipes. Mill grinders deliver finer and more consistent textures thanks to their mechanical precision, ideal for smooth and homogeneous pastes. The choice between mortar and mill grinders significantly affects the uniformity and texture quality of the final product.

Time Efficiency: Mortar Grinder vs Mill Grinder

Mortar grinders typically offer faster processing times for pastes due to their high-speed rotation and efficient grinding mechanism, reducing batch preparation from minutes to seconds. Mill grinders, while effective for larger quantities, often require longer processing times as their impact-based mechanism breaks down materials more slowly. Choosing a mortar grinder enhances time efficiency in laboratories and industrial settings where rapid paste preparation is critical.

Ease of Cleaning and Maintenance

Mortar grinders offer superior ease of cleaning due to their simple, removable components that prevent paste buildup, ensuring minimal residue retention. Mill grinders often have complex parts and narrow grinding chambers that complicate thorough cleaning and require more frequent maintenance. Choosing a mortar grinder for pastes reduces downtime and maintenance costs, enhancing overall operational efficiency.

Cost Comparison of Mortar Grinders and Mill Grinders

Mortar grinders typically have lower initial costs compared to mill grinders, making them more budget-friendly for small-scale paste preparation. Mill grinders, while more expensive upfront, offer higher efficiency and consistency for large-volume operations, which can reduce long-term operational costs. Considering maintenance expenses, mortar grinders incur minimal upkeep, whereas mill grinders may require specialized servicing, impacting overall cost-effectiveness.

Ideal Uses: When to Choose Mortar Over Mill Grinder

Mortar grinders excel in preparing small batches of pastes where controlled pressure and gentle grinding preserve ingredient texture and flavor, making them ideal for herbal pastes and delicate spice blends. Mill grinders are better suited for large-scale processing of harder substances requiring uniform particle size, such as grains or dry spices. Choosing a mortar grinder is ideal for artisanal applications demanding precise consistency and minimal heat generation to maintain paste quality.

Final Recommendations for Paste Preparation

Mortar grinders provide precise control and gentle grinding ideal for delicate pastes requiring minimal heat generation, preserving texture and ingredient integrity. Mill grinders, with their higher speed and capacity, efficiently process large volumes but risk overheating and altering paste consistency. For paste preparation prioritizing quality and texture, mortar grinders are recommended for small batches, while mill grinders suit high-volume, less sensitive applications.

Mortar grinder vs mill grinder for pastes Infographic

productvia.com

productvia.com