Pulse grinders deliver bursts of grinding power, allowing better control over particle size and preventing overheating, which preserves the powder's quality. Continuous grinders operate steadily, offering high efficiency for large batches but risk inconsistent particle size and heat buildup that can degrade delicate powders. Choosing between pulse and continuous grinders depends on the desired precision, batch size, and sensitivity of the powder being processed.

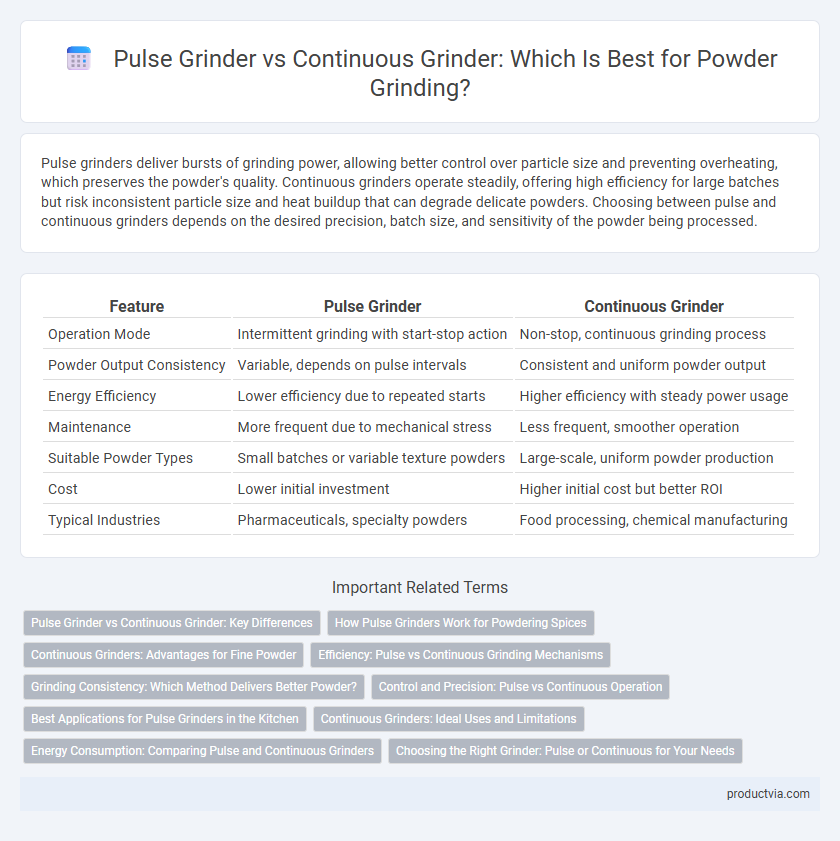

Table of Comparison

| Feature | Pulse Grinder | Continuous Grinder |

|---|---|---|

| Operation Mode | Intermittent grinding with start-stop action | Non-stop, continuous grinding process |

| Powder Output Consistency | Variable, depends on pulse intervals | Consistent and uniform powder output |

| Energy Efficiency | Lower efficiency due to repeated starts | Higher efficiency with steady power usage |

| Maintenance | More frequent due to mechanical stress | Less frequent, smoother operation |

| Suitable Powder Types | Small batches or variable texture powders | Large-scale, uniform powder production |

| Cost | Lower initial investment | Higher initial cost but better ROI |

| Typical Industries | Pharmaceuticals, specialty powders | Food processing, chemical manufacturing |

Pulse Grinder vs Continuous Grinder: Key Differences

Pulse grinders operate by delivering short bursts of grinding power, which allows for precise control over the particle size and reduces heat buildup in the powder, preserving its quality. Continuous grinders provide a steady, uninterrupted grinding process ideal for high-volume production but may generate more heat, potentially affecting the powder's properties. The choice between pulse and continuous grinding depends on the specific powder characteristics and production requirements, balancing precision with throughput efficiency.

How Pulse Grinders Work for Powdering Spices

Pulse grinders operate by delivering short, controlled bursts of power that prevent overheating and preserve the essential oils and aromas in spices. The intermittent grinding action ensures a consistent particle size, enhancing the flavor profile and texture of powdered spices. This method is especially effective for delicate or oily spices, maintaining their freshness and potency compared to the continuous grinding process.

Continuous Grinders: Advantages for Fine Powder

Continuous grinders offer superior consistency in producing fine powder due to their steady feed rate and uniform grinding action. These grinders maintain optimal particle size distribution, which is essential for applications requiring precise texture and high surface area. Their efficient heat dissipation prevents thermal degradation, preserving the quality of heat-sensitive powders.

Efficiency: Pulse vs Continuous Grinding Mechanisms

Pulse grinders deliver efficient powder grinding by using short, intense bursts of energy that minimize heat buildup and preserve material integrity, making them ideal for heat-sensitive powders. Continuous grinders operate with steady, constant motion, providing uniform particle size distribution but often generate more heat, which can reduce efficiency for delicate materials. Selecting between pulse and continuous grinding mechanisms depends on balancing energy use, material sensitivity, and desired powder consistency.

Grinding Consistency: Which Method Delivers Better Powder?

Pulse grinders deliver better powder grinding consistency by controlling the grinding intervals, allowing the material to cool between pulses and preventing overheating and clumping. Continuous grinders operate without breaks, which can cause heat buildup and lead to uneven particle size distribution in the powder. For precise and consistent powder production, pulse grinders are typically preferred due to improved temperature control and uniform particle size.

Control and Precision: Pulse vs Continuous Operation

Pulse grinders provide superior control and precision by delivering intermittent bursts of grinding, allowing for more accurate particle size adjustment and preventing overheating of powders. Continuous grinders operate at a steady pace, offering faster processing but with less precision in maintaining uniform particle size and temperature control. For applications requiring fine control over powder consistency and heat-sensitive materials, pulse grinding is the preferred method.

Best Applications for Pulse Grinders in the Kitchen

Pulse grinders excel in kitchens where precision and control are essential, such as grinding coffee beans or spices to a specific consistency. They deliver short bursts of power that prevent overheating and preserve the aroma and flavor of delicate ingredients. Ideal for small batches, pulse grinders ensure uniform particle size, enhancing the texture and taste of culinary creations.

Continuous Grinders: Ideal Uses and Limitations

Continuous grinders offer consistent particle size and high throughput rates, making them ideal for large-scale powder production in industries such as pharmaceuticals, food processing, and chemicals. They excel in uniform grinding of materials with low to moderate moisture content but are less effective with heat-sensitive powders due to friction-induced temperature rise. Maintenance complexity and higher initial investment can be limitations compared to pulse grinders, but their efficiency suits continuous production environments.

Energy Consumption: Comparing Pulse and Continuous Grinders

Pulse grinders operate with intermittent bursts of energy, resulting in lower overall energy consumption compared to continuous grinders, which run nonstop and consume more power. Continuous grinders maintain a steady grinding process ideal for large-scale powder production but often lead to higher energy costs due to constant operation. Energy efficiency in pulse grinders makes them suitable for small to medium batches, reducing electricity usage and operational expenses significantly.

Choosing the Right Grinder: Pulse or Continuous for Your Needs

Pulse grinders deliver precise bursts of power ideal for achieving consistent particle size in powders, preventing overheating and preserving flavor integrity. Continuous grinders offer faster processing for large-scale powder production, ensuring uniform output but with higher heat generation risk. Selecting between pulse and continuous grinders depends on volume requirements, desired powder quality, and thermal sensitivity of the material.

Pulse grinder vs continuous grinder for powder Infographic

productvia.com

productvia.com