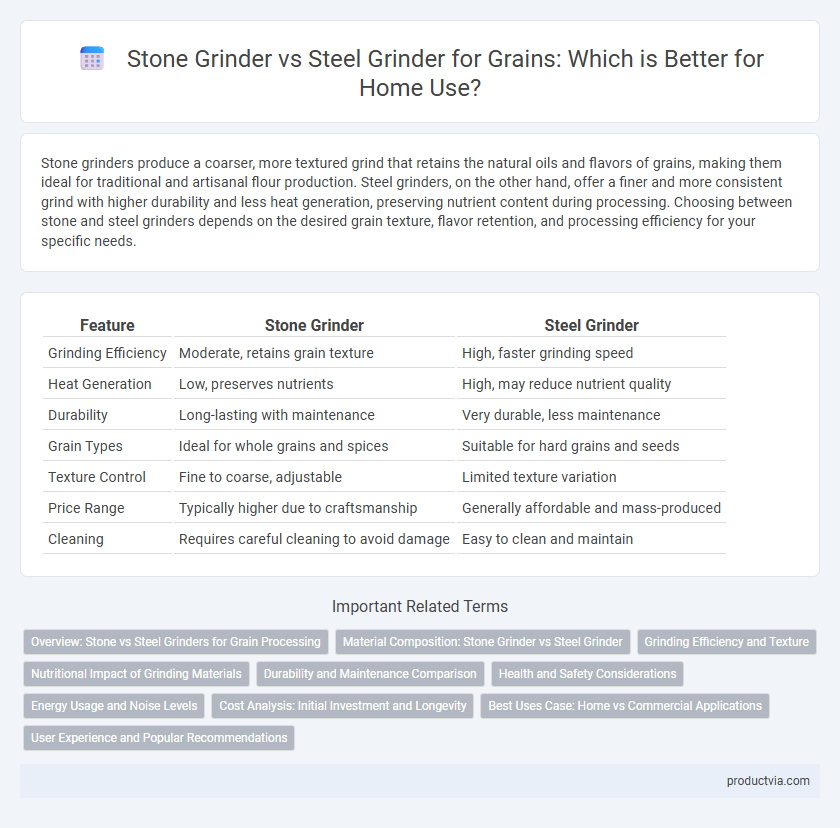

Stone grinders produce a coarser, more textured grind that retains the natural oils and flavors of grains, making them ideal for traditional and artisanal flour production. Steel grinders, on the other hand, offer a finer and more consistent grind with higher durability and less heat generation, preserving nutrient content during processing. Choosing between stone and steel grinders depends on the desired grain texture, flavor retention, and processing efficiency for your specific needs.

Table of Comparison

| Feature | Stone Grinder | Steel Grinder |

|---|---|---|

| Grinding Efficiency | Moderate, retains grain texture | High, faster grinding speed |

| Heat Generation | Low, preserves nutrients | High, may reduce nutrient quality |

| Durability | Long-lasting with maintenance | Very durable, less maintenance |

| Grain Types | Ideal for whole grains and spices | Suitable for hard grains and seeds |

| Texture Control | Fine to coarse, adjustable | Limited texture variation |

| Price Range | Typically higher due to craftsmanship | Generally affordable and mass-produced |

| Cleaning | Requires careful cleaning to avoid damage | Easy to clean and maintain |

Overview: Stone vs Steel Grinders for Grain Processing

Stone grinders offer traditional, slow-speed grinding that preserves the natural oils and nutrients in grains, producing a coarser texture ideal for whole grain flours. Steel grinders operate at higher speeds, providing finer, more uniform particle sizes and greater processing efficiency for large-scale grain milling. Stone grinders excel in flavor retention and texture variation, while steel grinders prioritize speed, precision, and ease of maintenance in grain processing.

Material Composition: Stone Grinder vs Steel Grinder

Stone grinders use natural or synthetic stones that provide a coarse-to-fine texture suited for traditional grain grinding, preserving nutrients by generating low heat during processing. Steel grinders feature hardened stainless steel blades or burrs designed for durability and precision, offering faster grinding speeds but potentially higher friction and heat buildup. The choice between stone and steel grinders depends on the desired texture, nutrient retention, and processing efficiency for grains like wheat, corn, and barley.

Grinding Efficiency and Texture

Stone grinders provide a slower, gentler grinding process that preserves the natural oils and nutrients in grains, resulting in a finer, more consistent texture ideal for whole grain flours. Steel grinders operate at higher speeds with sharp blades, offering greater grinding efficiency and faster processing but can generate heat that may affect the grain's flavor and texture. Choosing between stone and steel grinders depends on the desired balance between texture quality and grinding speed for specific grain processing needs.

Nutritional Impact of Grinding Materials

Stone grinders preserve more nutrients in grains due to their low heat generation and gentle grinding process, which minimizes nutrient degradation and oxidation. Steel grinders, while faster and more durable, can produce heat that may reduce the nutritional value by damaging heat-sensitive vitamins and enzymes. The porous surface of stone grinders also helps retain natural oils and fiber, enhancing the overall nutritional profile of ground grains.

Durability and Maintenance Comparison

Stone grinders offer exceptional durability due to their natural hardness and resistance to wear, ensuring long-lasting performance when grinding grains. Steel grinders, while generally robust, may require more frequent maintenance such as sharpening and rust prevention to maintain optimal efficiency. Stone grinders typically demand less maintenance overall, as their surfaces naturally resist grain residue buildup and require minimal upkeep.

Health and Safety Considerations

Stone grinders produce less heat during grinding, preserving the nutritional content and natural oils in grains, which supports better health benefits. In contrast, steel grinders may generate higher temperatures that can degrade nutrients and potentially release harmful metal particles, posing a safety risk. Stone grinders also minimize the risk of contamination and offer a more natural, chemical-free grinding process, making them a safer choice for health-conscious users.

Energy Usage and Noise Levels

Stone grinders for grains typically consume more energy due to slower grinding speeds and friction between the stone surfaces, but they produce a quieter operation compared to steel grinders. Steel grinders operate at higher speeds with less energy consumption, yet they generate more noise due to metal-on-metal contact and vibrating components. Energy efficiency of steel grinders is often preferred in commercial settings despite the trade-off of increased noise levels.

Cost Analysis: Initial Investment and Longevity

Stone grinders typically demand a higher initial investment, ranging from $200 to $500, due to their durable natural material and traditional craftsmanship. Steel grinders, priced between $100 and $300, offer a more affordable upfront cost but may experience faster wear and require replacement or maintenance within 5 to 10 years. When assessing longevity, stone grinders often last over 20 years with minimal maintenance, presenting better long-term value despite the steeper initial expense.

Best Uses Case: Home vs Commercial Applications

Stone grinders excel in home settings due to their ability to retain grain nutrients and produce a coarse, textured flour ideal for artisanal baking. Steel grinders are preferred in commercial applications because of their durability, efficiency, and capacity to handle large quantities of grains with consistent fine grinding. The choice hinges on whether the priority is traditional texture and flavor or high-volume, uniform output.

User Experience and Popular Recommendations

Stone grinders offer a gentler grinding process, preserving the natural flavor and nutrients of grains, which users often find results in superior texture and taste. Steel grinders are preferred for their durability and faster processing, making them popular among users who prioritize efficiency and versatility for various grain types. Popular recommendations emphasize stone grinders for artisanal baking and steel grinders for commercial or high-volume use due to their distinct performance benefits.

Stone grinder vs Steel grinder for grains Infographic

productvia.com

productvia.com