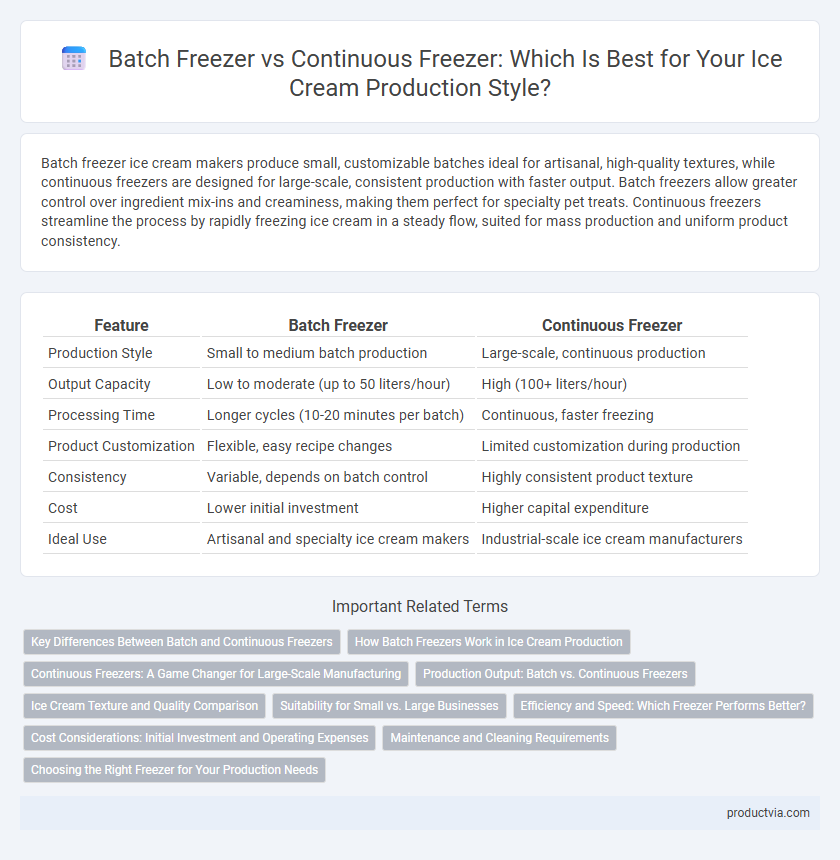

Batch freezer ice cream makers produce small, customizable batches ideal for artisanal, high-quality textures, while continuous freezers are designed for large-scale, consistent production with faster output. Batch freezers allow greater control over ingredient mix-ins and creaminess, making them perfect for specialty pet treats. Continuous freezers streamline the process by rapidly freezing ice cream in a steady flow, suited for mass production and uniform product consistency.

Table of Comparison

| Feature | Batch Freezer | Continuous Freezer |

|---|---|---|

| Production Style | Small to medium batch production | Large-scale, continuous production |

| Output Capacity | Low to moderate (up to 50 liters/hour) | High (100+ liters/hour) |

| Processing Time | Longer cycles (10-20 minutes per batch) | Continuous, faster freezing |

| Product Customization | Flexible, easy recipe changes | Limited customization during production |

| Consistency | Variable, depends on batch control | Highly consistent product texture |

| Cost | Lower initial investment | Higher capital expenditure |

| Ideal Use | Artisanal and specialty ice cream makers | Industrial-scale ice cream manufacturers |

Key Differences Between Batch and Continuous Freezers

Batch freezers produce small, controlled quantities of ice cream with precise ingredient adjustments, ideal for artisanal or small-scale production. Continuous freezers operate non-stop, generating large volumes with consistent texture and efficiency, suitable for industrial-scale manufacturing. Key differences include production speed, volume capacity, and customization flexibility, where batch freezers offer greater control over the freezing process and continuous freezers provide high-speed output.

How Batch Freezers Work in Ice Cream Production

Batch freezers operate by freezing a specific volume of ice cream mix in a single cycle, using a refrigerated cylinder and a rotating dasher to churn and incorporate air uniformly. This process allows precise control over texture and overrun, making batch freezers ideal for small to medium-scale production with artisanal quality. The intermittent freezing mechanism enables customization of mix-ins and flavors between batches, enhancing product variety and consistency.

Continuous Freezers: A Game Changer for Large-Scale Manufacturing

Continuous freezers revolutionize large-scale ice cream manufacturing by offering efficient, uninterrupted production with consistent product texture and quality. Unlike batch freezers that process limited quantities in cycles, continuous freezers streamline the freezing and aeration process, boosting output capacity and reducing labor costs. Their advanced technology ensures uniform incorporation of air and mix, resulting in smooth ice cream ideal for high-demand commercial environments.

Production Output: Batch vs. Continuous Freezers

Batch freezers produce ice cream in limited quantities per cycle, making them ideal for small to medium-scale production with high customization options. Continuous freezers enable large-scale, non-stop ice cream production, offering higher output rates and consistent texture suitable for commercial manufacturers. Choosing between batch and continuous freezers depends on balancing production volume needs and product variety requirements.

Ice Cream Texture and Quality Comparison

Batch freezers produce ice cream with a denser, creamier texture by freezing smaller quantities at a time, allowing better control over air incorporation and consistency. Continuous freezers operate by continuously freezing and aerating the mix, resulting in higher output but a lighter, softer texture with less control over overrun. For premium ice cream texture and quality, batch freezers are preferred due to their ability to create richer mouthfeel and uniform particle size.

Suitability for Small vs. Large Businesses

Batch freezers are ideal for small businesses due to their ability to produce customizable, small quantities of ice cream with greater flavor flexibility and minimal initial investment. Continuous freezers suit large-scale production, delivering high output volumes efficiently while maintaining consistent quality, making them essential for mass production and commercial ice cream manufacturing. Small businesses benefit from batch freezers' versatility and cost-effectiveness, whereas large operations rely on continuous freezers for scalability and speed.

Efficiency and Speed: Which Freezer Performs Better?

Batch freezers offer greater flexibility and control for small to medium ice cream production, enabling precise ingredient mixing and texture adjustments but with slower output rates. Continuous freezers excel in large-scale operations by rapidly producing consistent ice cream with high efficiency, thanks to uninterrupted freezing and aeration processes that maximize speed and minimize labor costs. For businesses prioritizing speed and operational efficiency, continuous freezers outperform batch freezers in maintaining volume and consistent product quality under high demand.

Cost Considerations: Initial Investment and Operating Expenses

Batch freezers typically require a lower initial investment compared to continuous freezers, making them ideal for small to medium-scale ice cream production. Continuous freezers, while more expensive upfront, offer greater efficiency and lower operating costs per unit, benefiting large-scale manufacturers. Evaluating production volume and budget constraints is crucial for choosing the most cost-effective freezer type.

Maintenance and Cleaning Requirements

Batch freezers require thorough cleaning between each batch, making maintenance labor-intensive but essential for product quality and preventing cross-contamination. Continuous freezers offer automated cleaning cycles and reduced downtime, enhancing efficiency for large-scale production environments. Understanding these differences helps manufacturers select equipment that balances maintenance demands with production volume needs.

Choosing the Right Freezer for Your Production Needs

Selecting the ideal ice cream maker hinges on understanding Batch Freezer and Continuous Freezer production styles. Batch Freezers offer flexibility for small to medium-scale production with varied flavors and faster changeover times, while Continuous Freezers excel in high-volume, consistent output suited for large-scale commercial operations. Evaluating production capacity, flavor variety, and operational efficiency ensures alignment with specific manufacturing goals.

Batch Freezer vs Continuous Freezer for Production Style Infographic

productvia.com

productvia.com