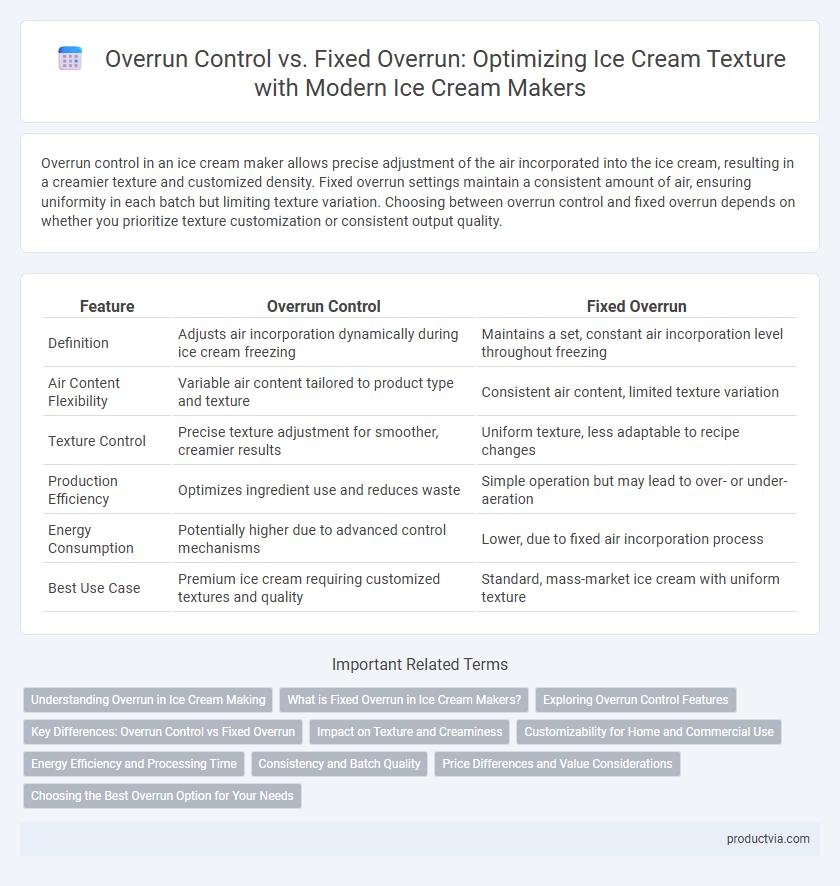

Overrun control in an ice cream maker allows precise adjustment of the air incorporated into the ice cream, resulting in a creamier texture and customized density. Fixed overrun settings maintain a consistent amount of air, ensuring uniformity in each batch but limiting texture variation. Choosing between overrun control and fixed overrun depends on whether you prioritize texture customization or consistent output quality.

Table of Comparison

| Feature | Overrun Control | Fixed Overrun |

|---|---|---|

| Definition | Adjusts air incorporation dynamically during ice cream freezing | Maintains a set, constant air incorporation level throughout freezing |

| Air Content Flexibility | Variable air content tailored to product type and texture | Consistent air content, limited texture variation |

| Texture Control | Precise texture adjustment for smoother, creamier results | Uniform texture, less adaptable to recipe changes |

| Production Efficiency | Optimizes ingredient use and reduces waste | Simple operation but may lead to over- or under-aeration |

| Energy Consumption | Potentially higher due to advanced control mechanisms | Lower, due to fixed air incorporation process |

| Best Use Case | Premium ice cream requiring customized textures and quality | Standard, mass-market ice cream with uniform texture |

Understanding Overrun in Ice Cream Making

Overrun in ice cream making refers to the amount of air incorporated into the mixture, significantly affecting texture and volume, with typical values ranging from 20% to 100%. Overrun control systems precisely regulate this air content, ensuring consistent creaminess and preventing excess air that could lead to coarse texture, while fixed overrun settings provide a set air incorporation rate suitable for standard recipes. Understanding the balance between overrun control and fixed overrun optimizes ice cream quality by delivering desired density, smoothness, and taste in commercial or home ice cream makers.

What is Fixed Overrun in Ice Cream Makers?

Fixed overrun in ice cream makers refers to a preset amount of air incorporated into the ice cream during freezing, ensuring consistent texture and volume in each batch. This controlled air injection improves creaminess and reduces density, resulting in a product that meets specific quality standards. Unlike variable overrun, fixed overrun settings optimize production efficiency by maintaining uniformity across all batches.

Exploring Overrun Control Features

Overrun control in ice cream makers allows precise adjustment of air incorporation, directly influencing texture, creaminess, and volume of the final product. Fixed overrun systems provide a consistent air-to-mixture ratio, ensuring uniformity but limiting customization for different recipes or preferences. Exploring overrun control features enables users to optimize ice cream density and mouthfeel, enhancing product quality and meeting diverse consumer demands.

Key Differences: Overrun Control vs Fixed Overrun

Overrun control in an ice cream maker adjusts the amount of air incorporated during freezing, allowing precise customization of texture and density, while fixed overrun maintains a constant air volume for consistent results. Overrun control systems offer better adaptability for different recipes and ingredients, enhancing creaminess and mouthfeel. Fixed overrun simplifies the process by reducing the need for adjustments but may limit the variation in ice cream quality and style.

Impact on Texture and Creaminess

Overrun control in ice cream makers precisely manages the amount of air incorporated, directly affecting the ice cream's texture and creaminess by producing a smoother, denser product. Fixed overrun settings often result in inconsistent air distribution, which can lead to a coarser texture and less creamy mouthfeel. Optimal overrun control is essential for achieving the ideal balance between lightness and richness in homemade ice cream.

Customizability for Home and Commercial Use

Overrun control in ice cream makers allows precise adjustment of air incorporation, enhancing texture and volume tailored to specific recipes, ideal for both home users seeking artisanal quality and commercial operators requiring consistent product standards. Fixed overrun systems provide a set level of air integration, simplifying operation but limiting customization, which suits beginners or high-volume production where uniformity is prioritized. Customizable overrun options offer superior flexibility for crafting unique textures and optimizing product appeal across diverse market needs.

Energy Efficiency and Processing Time

Overrun control in ice cream makers allows precise adjustment of the air incorporated, optimizing energy consumption by reducing compressor workload and minimizing freezing time compared to fixed overrun systems. Fixed overrun models operate at a constant air incorporation rate, often leading to longer processing times and higher energy use due to less efficient air-to-ice ratio management. By enabling customized overrun settings, energy efficiency improves and overall processing time decreases, resulting in faster production and lower operational costs.

Consistency and Batch Quality

Overrun control in an ice cream maker allows precise adjustment of air incorporation, resulting in consistent texture and smoother batch quality with each production cycle. Fixed overrun settings limit the ability to customize air content, often causing variability in product density and creaminess across different batches. Maintaining optimal overrun control is essential for achieving uniform mouthfeel and overall superior ice cream quality.

Price Differences and Value Considerations

Overrun control in ice cream makers allows precise adjustment of air incorporation, enhancing texture and creaminess but often comes with a higher price due to advanced technology. Fixed overrun models are generally more affordable, providing consistent air content but less customization in product density and mouthfeel. Choosing between them depends on balancing budget constraints against the desired quality and versatility of the final ice cream product.

Choosing the Best Overrun Option for Your Needs

Overrun control in ice cream makers allows precise adjustment of air incorporation, resulting in customizable texture and creaminess, while fixed overrun offers a consistent, predetermined air content for reliable output. Choosing the best overrun option depends on your desired ice cream quality and production scale, with overrun control favored by artisan makers seeking texture variety and fixed overrun preferred for standard commercial consistency. Balancing operational complexity and end-product preference helps determine the ideal overrun system to optimize ice cream quality and efficiency.

Overrun control vs Fixed overrun for ice cream maker Infographic

productvia.com

productvia.com