Copper bottom cookware offers excellent heat conductivity, ensuring rapid and even heating on induction stoves, while stainless steel bottoms provide greater durability and resistance to corrosion. Stainless steel is magnetic, making it compatible with induction cooktops, whereas pure copper lacks magnetic properties and may require a layered base to work effectively. Choosing between copper and stainless steel bottoms depends on the balance of heat efficiency and long-term durability desired for induction cooking.

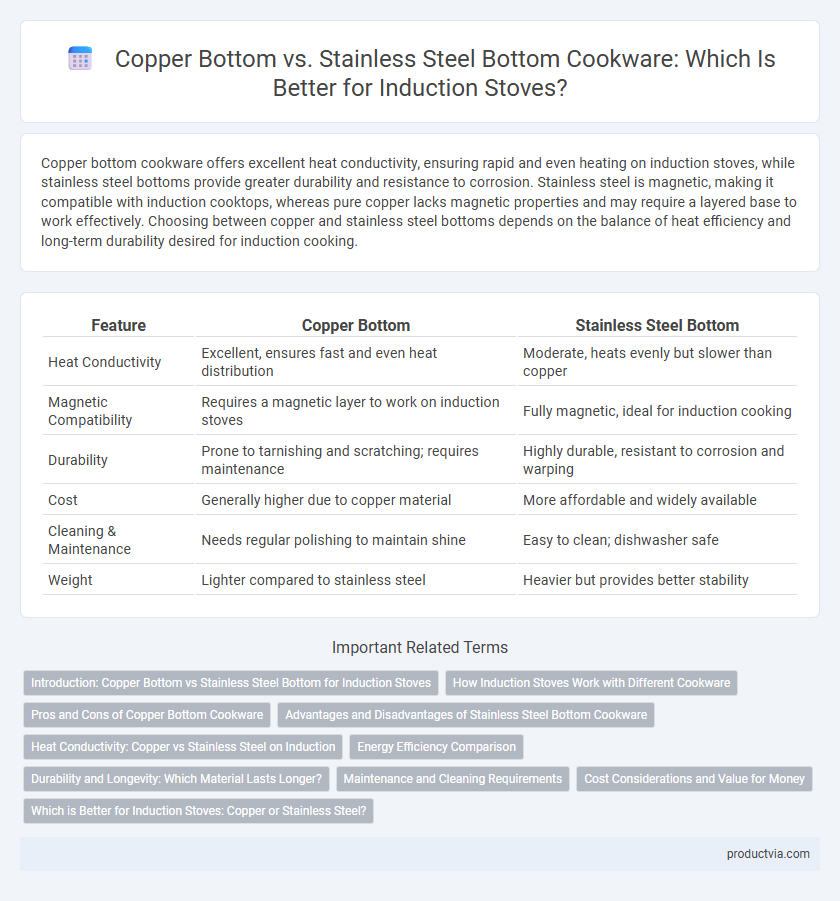

Table of Comparison

| Feature | Copper Bottom | Stainless Steel Bottom |

|---|---|---|

| Heat Conductivity | Excellent, ensures fast and even heat distribution | Moderate, heats evenly but slower than copper |

| Magnetic Compatibility | Requires a magnetic layer to work on induction stoves | Fully magnetic, ideal for induction cooking |

| Durability | Prone to tarnishing and scratching; requires maintenance | Highly durable, resistant to corrosion and warping |

| Cost | Generally higher due to copper material | More affordable and widely available |

| Cleaning & Maintenance | Needs regular polishing to maintain shine | Easy to clean; dishwasher safe |

| Weight | Lighter compared to stainless steel | Heavier but provides better stability |

Introduction: Copper Bottom vs Stainless Steel Bottom for Induction Stoves

Copper bottom cookware offers superior thermal conductivity, ensuring rapid and even heat distribution ideal for induction stoves. In contrast, stainless steel bottoms provide excellent durability and resistance to corrosion while maintaining efficient magnetic properties necessary for induction cooking. Selecting between copper and stainless steel bottoms depends on the balance between heat performance and long-term cookware maintenance on induction surfaces.

How Induction Stoves Work with Different Cookware

Induction stoves operate by creating a magnetic field that directly heats the cookware, requiring materials with ferromagnetic properties for efficient heat transfer. Copper bottom pans, while excellent conductors of heat, are typically non-magnetic and thus less compatible with induction hobs unless paired with a magnetic stainless steel layer. Stainless steel bottoms, especially those specifically designed for induction with magnetic properties, ensure optimal energy transfer and consistent cooking performance on induction stoves.

Pros and Cons of Copper Bottom Cookware

Copper bottom cookware offers exceptional thermal conductivity, ensuring rapid and even heat distribution on induction stoves, which enhances cooking precision. However, copper is prone to tarnishing and requires regular maintenance to keep its appearance and performance optimal. Its higher cost and potential reactivity with acidic foods make it less durable compared to stainless steel bottom cookware, which is more resistant to corrosion and easier to clean.

Advantages and Disadvantages of Stainless Steel Bottom Cookware

Stainless steel bottom cookware offers superior durability and corrosion resistance, making it highly compatible with induction stoves due to its magnetic properties. It provides even heating but may have less thermal conductivity compared to copper bottoms, potentially causing slower heat distribution. Stainless steel is easier to maintain and less prone to warping, though it can be heavier and more expensive than copper-bottom options.

Heat Conductivity: Copper vs Stainless Steel on Induction

Copper bottom cookware offers superior heat conductivity compared to stainless steel bottoms on induction stoves, ensuring faster and more even heat distribution for precise cooking control. Stainless steel bottoms provide durability but generally have lower thermal conductivity, which can result in slower heat transfer and occasional hot spots. The ideal choice depends on balancing the need for quick, uniform heat with the cookware's overall resilience on induction cooktops.

Energy Efficiency Comparison

Copper bottom cookware heats up quickly due to its excellent thermal conductivity, resulting in faster cooking times and reduced energy consumption on induction stoves. Stainless steel bottoms, while durable and resistant to corrosion, have lower thermal conductivity, causing slower heat transfer and potentially higher energy usage. Choosing copper bottom pans optimizes energy efficiency by maximizing heat distribution and minimizing wasted power during induction cooking.

Durability and Longevity: Which Material Lasts Longer?

Copper bottom cookware offers excellent thermal conductivity but is prone to tarnishing and requires regular maintenance, which can affect its longevity on induction stoves. Stainless steel bottoms are highly durable, resistant to corrosion, and maintain their structural integrity over prolonged use, making them ideal for long-term performance on induction cooktops. For maximum durability and lifespan, stainless steel bottom cookware generally outperforms copper on induction stoves.

Maintenance and Cleaning Requirements

Copper bottom cookware requires careful maintenance to prevent tarnishing and discoloration, often needing gentle hand washing with mild detergents and regular polishing to maintain its appearance. Stainless steel bottoms offer superior durability and ease of cleaning, typically allowing dishwasher use and resisting stains or corrosion from acidic foods. For induction stove users, stainless steel bottom cookware is preferred due to its low maintenance and compatibility with common cleaning methods.

Cost Considerations and Value for Money

Copper bottom cookware typically costs more due to superior heat conductivity and durability but may not always offer the best value for induction stoves, as copper is less magnetic and may require a stainless steel layer for compatibility, increasing price. Stainless steel bottom pots are generally more affordable, provide excellent magnetic properties essential for induction cooking, and offer long-term value through resistance to warping and corrosion. Evaluating total cost alongside performance ensures consumers invest wisely in cookware that maximizes both efficiency and budget on induction stoves.

Which is Better for Induction Stoves: Copper or Stainless Steel?

Copper bottom cookware offers excellent heat conductivity, ensuring rapid and even heating on induction stoves, but it requires a magnetic stainless steel layer to be compatible with induction technology. Stainless steel bottom cookware is highly durable, corrosion-resistant, and inherently magnetic, making it directly compatible and efficient for induction cooking. For optimal induction stove performance, stainless steel bottom cookware provides better durability and compatibility, while copper bottom excels in heat distribution when combined with a magnetic base.

Copper bottom vs stainless steel bottom for induction stove Infographic

productvia.com

productvia.com