Copper coils offer superior electrical conductivity and heat transfer efficiency compared to aluminum coils, making them ideal for induction stove cores. Their higher durability and resistance to corrosion ensure longer lifespan and consistent performance in kitchen appliances. While aluminum coils are lighter and more cost-effective, copper remains the preferred choice for optimal induction heating and energy efficiency.

Table of Comparison

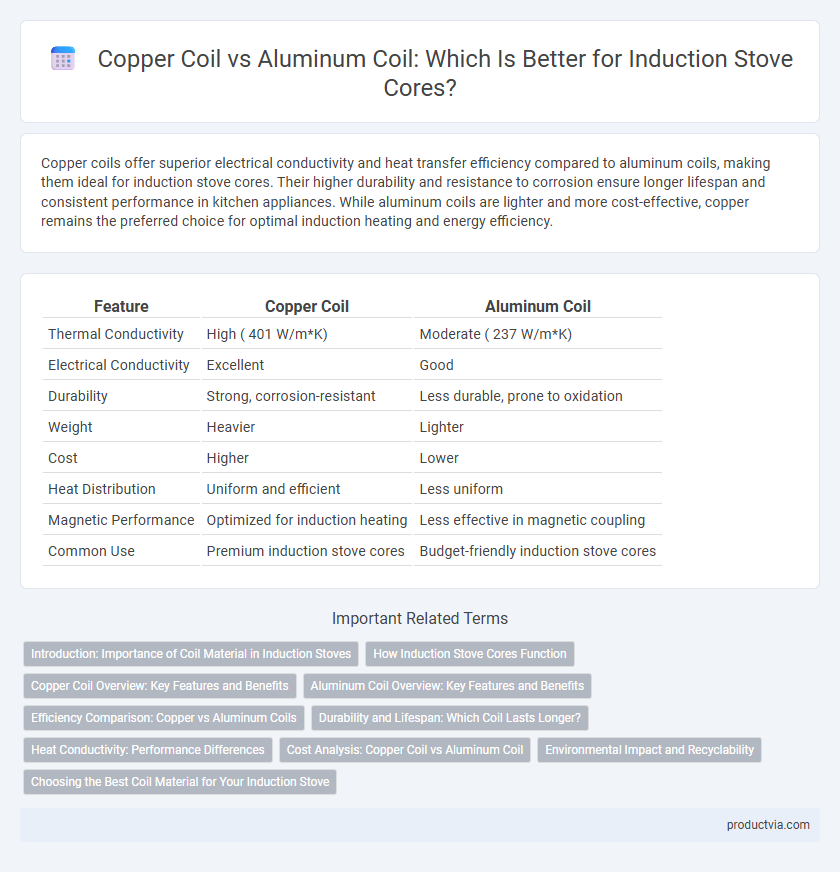

| Feature | Copper Coil | Aluminum Coil |

|---|---|---|

| Thermal Conductivity | High ( 401 W/m*K) | Moderate ( 237 W/m*K) |

| Electrical Conductivity | Excellent | Good |

| Durability | Strong, corrosion-resistant | Less durable, prone to oxidation |

| Weight | Heavier | Lighter |

| Cost | Higher | Lower |

| Heat Distribution | Uniform and efficient | Less uniform |

| Magnetic Performance | Optimized for induction heating | Less effective in magnetic coupling |

| Common Use | Premium induction stove cores | Budget-friendly induction stove cores |

Introduction: Importance of Coil Material in Induction Stoves

The coil material in an induction stove significantly influences its efficiency and heat distribution. Copper coils offer superior electrical conductivity and heat transfer compared to aluminum coils, resulting in faster heating and better energy efficiency. Selecting the right coil material is essential for optimizing the stove's performance and durability.

How Induction Stove Cores Function

Copper coils provide superior electrical conductivity in induction stove cores, creating stronger electromagnetic fields for efficient heat generation. Aluminum coils, while more cost-effective and lightweight, have lower conductivity, resulting in less efficient induction heating performance. The core's coil material directly impacts the stove's ability to induce eddy currents in cookware, influencing overall cooking speed and energy consumption.

Copper Coil Overview: Key Features and Benefits

Copper coils in induction stove cores offer superior electrical conductivity, which enhances energy efficiency and faster heating performance. Their excellent thermal conductivity ensures uniform heat distribution, reducing hotspots and improving cooking precision. Copper's durability and corrosion resistance also contribute to the coil's long lifespan and reliability in induction stove applications.

Aluminum Coil Overview: Key Features and Benefits

Aluminum coils in induction stove cores offer superior heat conductivity and lightweight properties, enhancing energy efficiency and rapid temperature response. The corrosion resistance and cost-effectiveness of aluminum make it a preferred choice for durable and affordable induction cookware. Their excellent thermal conductivity supports even heating, reducing hotspots and improving cooking performance.

Efficiency Comparison: Copper vs Aluminum Coils

Copper coils provide superior electrical conductivity compared to aluminum coils, resulting in higher energy efficiency and faster heat transfer in induction stove cores. Aluminum coils, while lighter and more affordable, have lower conductivity, causing increased electrical resistance and reduced overall efficiency. The enhanced performance of copper coils translates to quicker cooking times and lower energy consumption in induction stoves.

Durability and Lifespan: Which Coil Lasts Longer?

Copper coil cores for induction stoves exhibit superior durability and lifespan compared to aluminum coils due to copper's higher thermal conductivity and resistance to oxidation. Copper's robust nature minimizes wear and maintains efficiency over prolonged use, while aluminum coils tend to degrade faster under consistent heat exposure. Choosing a copper coil enhances the induction stove's long-term performance and reliability.

Heat Conductivity: Performance Differences

Copper coil cores in induction stoves exhibit superior heat conductivity, transferring heat more efficiently compared to aluminum coils. This higher thermal conductivity results in faster heating times and more precise temperature control for cooking. Despite being more expensive, copper coils enhance overall induction stove performance due to their excellent heat conduction properties.

Cost Analysis: Copper Coil vs Aluminum Coil

Copper coils generally incur higher initial costs due to copper's superior electrical conductivity and durability, enhancing the induction stove's efficiency and lifespan. Aluminum coils offer a cost-effective alternative with lower material expenses and adequate performance but may require more frequent replacements due to lower thermal conductivity and susceptibility to wear. A thorough cost analysis must balance upfront investment with long-term maintenance and energy efficiency when choosing between copper and aluminum coils for induction stove cores.

Environmental Impact and Recyclability

Copper coils in induction stove cores offer superior recyclability and lower environmental impact due to copper's high recovery rate and reduced energy consumption during recycling. Aluminum coils, while lighter and less expensive, pose environmental challenges from lower recycling efficiency and the energy-intensive extraction process. Sustainable manufacturing favors copper for its closed-loop recyclability and decreased ecological footprint compared to aluminum alternatives.

Choosing the Best Coil Material for Your Induction Stove

Copper coils provide superior electrical conductivity and heat transfer efficiency for induction stove cores, ensuring faster and more uniform heating. Aluminum coils are lighter and more cost-effective but offer lower conductivity, which may reduce cooking performance and energy efficiency. Selecting copper coils enhances durability and responsiveness, making them the best choice for high-performance induction stoves.

Copper Coil vs Aluminum Coil for Induction Stove Core Infographic

productvia.com

productvia.com