High-frequency switching in induction stoves generates a rapidly alternating electromagnetic field, enabling faster and more efficient heating of pet-safe cookware. Low-frequency switching produces slower electromagnetic oscillations, often resulting in uneven heat distribution and longer cooking times. Choosing high-frequency switching improves energy efficiency and ensures safer, more consistent cooking for pet-friendly meals.

Table of Comparison

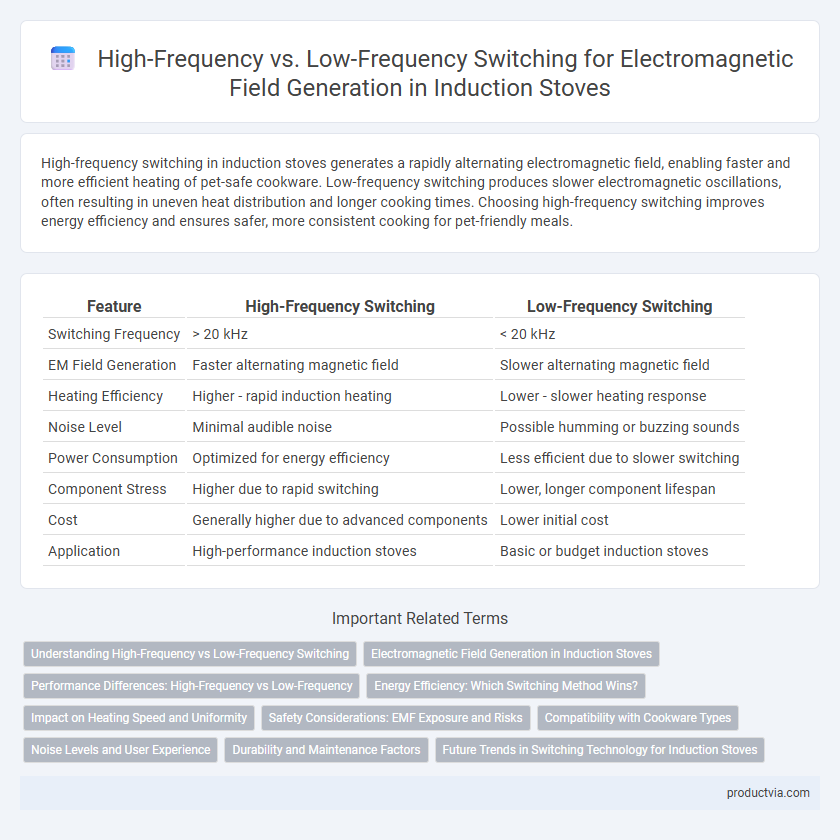

| Feature | High-Frequency Switching | Low-Frequency Switching |

|---|---|---|

| Switching Frequency | > 20 kHz | < 20 kHz |

| EM Field Generation | Faster alternating magnetic field | Slower alternating magnetic field |

| Heating Efficiency | Higher - rapid induction heating | Lower - slower heating response |

| Noise Level | Minimal audible noise | Possible humming or buzzing sounds |

| Power Consumption | Optimized for energy efficiency | Less efficient due to slower switching |

| Component Stress | Higher due to rapid switching | Lower, longer component lifespan |

| Cost | Generally higher due to advanced components | Lower initial cost |

| Application | High-performance induction stoves | Basic or budget induction stoves |

Understanding High-Frequency vs Low-Frequency Switching

High-frequency switching in induction stoves typically operates above 20 kHz, enabling faster and more efficient electromagnetic field generation that heats cookware quickly and uniformly. Low-frequency switching, often below 20 kHz, produces a slower electromagnetic response, leading to less efficient heat transfer and potential noise during operation. Selecting high-frequency switching enhances energy efficiency, reduces heat loss, and minimizes audible noise, optimizing induction stove performance.

Electromagnetic Field Generation in Induction Stoves

High-frequency switching in induction stoves generates a rapidly alternating electromagnetic field, typically between 20 kHz and 100 kHz, enhancing heat transfer efficiency and allowing precise temperature control. Low-frequency switching, usually below 20 kHz, produces a slower alternating magnetic field, resulting in less efficient energy transfer and slower heating response times. Optimizing switching frequency directly impacts electromagnetic field strength, cookware compatibility, and overall stove performance.

Performance Differences: High-Frequency vs Low-Frequency

High-frequency switching in induction stoves generates electromagnetic fields that enable faster and more efficient heating with precise temperature control, reducing energy loss. Low-frequency switching produces slower heating response with less efficient energy transfer, often causing uneven cooking performance. High-frequency systems also minimize audible noise and improve overall user experience by offering smoother power modulation.

Energy Efficiency: Which Switching Method Wins?

High-frequency switching in induction stoves enables rapid electromagnetic field modulation, resulting in more precise and efficient energy transfer to the cookware, reducing power loss and heat dissipation. Low-frequency switching tends to generate stronger electromagnetic interference and less focused energy delivery, causing lower overall energy efficiency. Consequently, high-frequency switching models consistently outperform low-frequency counterparts in minimizing energy consumption and maximizing cooking efficiency.

Impact on Heating Speed and Uniformity

High-frequency switching in induction stoves generates more rapid and concentrated electromagnetic fields, significantly enhancing heating speed and resulting in faster cooking times. This switching frequency also improves heating uniformity by minimizing hotspots and ensuring even energy distribution across the cookware surface. In contrast, low-frequency switching produces slower heating responses and less uniform temperature profiles, potentially leading to uneven cooking and reduced efficiency.

Safety Considerations: EMF Exposure and Risks

High-frequency switching in induction stoves generates electromagnetic fields (EMF) at frequencies typically between 20 kHz and 100 kHz, which reduces exposure time and minimizes EMF penetration into the body, enhancing user safety. Low-frequency switching, often below 20 kHz, produces stronger and deeper-penetrating electromagnetic fields that may increase the risk of interference with medical devices such as pacemakers. Safety standards like the ICNIRP guidelines recommend high-frequency operation to keep EMF exposure within safe limits, reducing potential health risks associated with prolonged use.

Compatibility with Cookware Types

High-frequency switching in induction stoves generates a rapidly oscillating electromagnetic field that is highly compatible with a wide range of cookware types, including thin and specialty pans, due to its ability to produce precise heat control. Low-frequency switching creates a slower oscillating field, which is typically more compatible with traditional ferromagnetic cookware but may cause uneven heating or inefficiencies with thinner or non-standard materials. Choosing the appropriate frequency depends on the stove's intended use and the diversity of cookware, ensuring optimal performance and energy efficiency.

Noise Levels and User Experience

High-frequency switching in induction stoves generates electromagnetic fields with frequencies typically above 20 kHz, resulting in minimal audible noise and a smoother user experience. Low-frequency switching, often below 20 kHz, can produce noticeable buzzing or humming sounds that may affect user comfort during prolonged use. Optimizing the switching frequency balances efficient electromagnetic field generation with reduced acoustic noise, enhancing overall kitchen usability.

Durability and Maintenance Factors

High-frequency switching in induction stoves generates electromagnetic fields with greater precision, reducing heat stress on components and enhancing overall durability. Low-frequency switching often causes more significant thermal cycling, leading to faster wear and increased maintenance requirements. Choosing high-frequency switching improves longevity and minimizes downtime, lowering long-term maintenance costs for induction cooktops.

Future Trends in Switching Technology for Induction Stoves

High-frequency switching in induction stoves enhances energy efficiency and precise temperature control by rapidly modulating electromagnetic fields, while low-frequency switching offers simpler design but less responsiveness. Emerging future trends emphasize integrating gallium nitride (GaN) transistors for even higher switching frequencies, enabling compact, lightweight power modules with reduced heat loss. These advancements promote faster heating cycles and improved durability, aligning with consumer demand for smarter, more energy-efficient cooking appliances.

High-frequency switching vs Low-frequency switching for electromagnetic field generation Infographic

productvia.com

productvia.com