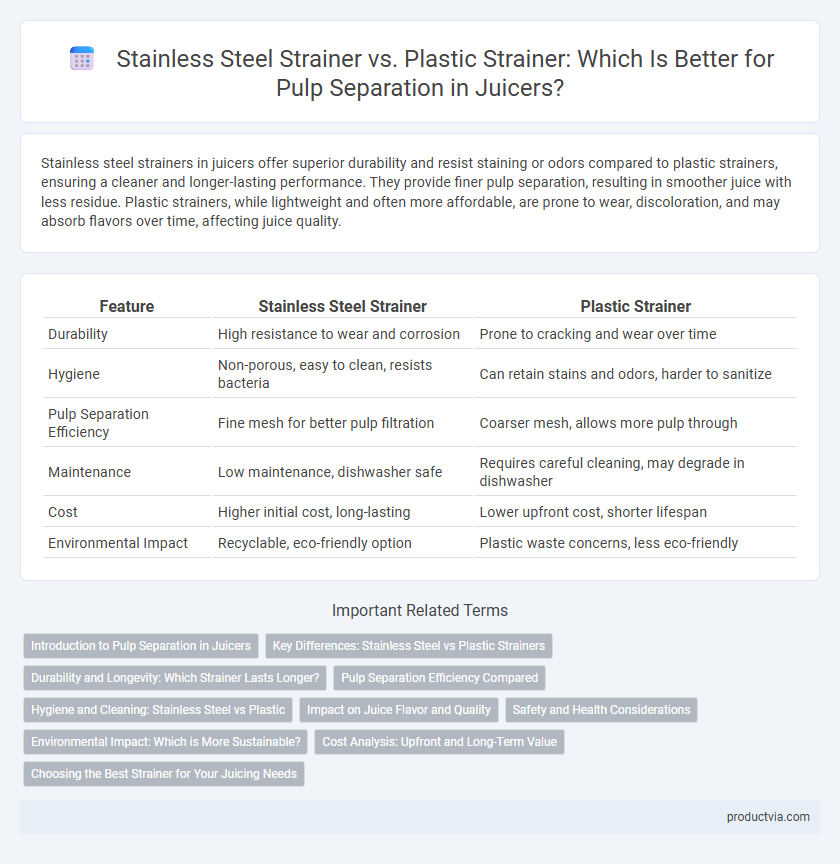

Stainless steel strainers in juicers offer superior durability and resist staining or odors compared to plastic strainers, ensuring a cleaner and longer-lasting performance. They provide finer pulp separation, resulting in smoother juice with less residue. Plastic strainers, while lightweight and often more affordable, are prone to wear, discoloration, and may absorb flavors over time, affecting juice quality.

Table of Comparison

| Feature | Stainless Steel Strainer | Plastic Strainer |

|---|---|---|

| Durability | High resistance to wear and corrosion | Prone to cracking and wear over time |

| Hygiene | Non-porous, easy to clean, resists bacteria | Can retain stains and odors, harder to sanitize |

| Pulp Separation Efficiency | Fine mesh for better pulp filtration | Coarser mesh, allows more pulp through |

| Maintenance | Low maintenance, dishwasher safe | Requires careful cleaning, may degrade in dishwasher |

| Cost | Higher initial cost, long-lasting | Lower upfront cost, shorter lifespan |

| Environmental Impact | Recyclable, eco-friendly option | Plastic waste concerns, less eco-friendly |

Introduction to Pulp Separation in Juicers

Stainless steel strainers in juicers provide superior durability and resistance to corrosion compared to plastic strainers, ensuring efficient pulp separation under high pressure. The fine mesh design of stainless steel effectively filters out pulp fibers, resulting in clearer juice with minimal residue. Plastic strainers, while lightweight and cost-effective, tend to degrade over time and may allow more pulp particles to pass through, affecting juice purity.

Key Differences: Stainless Steel vs Plastic Strainers

Stainless steel strainers offer superior durability and resistance to corrosion compared to plastic strainers, making them ideal for long-term use in juicing pulp separation. They provide finer filtration, resulting in smoother juice with minimal pulp residue, while plastic strainers tend to wear out quickly and may retain odors or stains. Stainless steel is also more hygienic as it resists bacterial buildup better than plastic, ensuring safer and cleaner juice extraction.

Durability and Longevity: Which Strainer Lasts Longer?

Stainless steel strainers offer superior durability and longevity compared to plastic strainers, resisting corrosion and wear even after prolonged use. Their robust construction withstands frequent cleaning and high pressure without cracking or deforming, ensuring consistent pulp separation performance. Plastic strainers, while lightweight and inexpensive, tend to degrade faster due to exposure to heat, acidic fruit juices, and mechanical stress, resulting in shorter service life.

Pulp Separation Efficiency Compared

Stainless steel strainers offer superior pulp separation efficiency compared to plastic strainers due to their fine mesh design and durability, which prevents clogging and ensures consistent juice flow. The rigid structure of stainless steel maintains optimal filtration over time, while plastic strainers can warp or degrade, reducing performance. Stainless steel also resists stains and odors, preserving juice purity during pulp separation.

Hygiene and Cleaning: Stainless Steel vs Plastic

Stainless steel strainers offer superior hygiene due to their non-porous surface, which resists bacterial buildup and staining better than plastic strainers. They are easier to clean thoroughly, often dishwasher safe, and maintain their integrity over time without absorbing odors or discoloration. Plastic strainers can develop micro-scratches that harbor bacteria, making them less sanitary and more challenging to clean effectively.

Impact on Juice Flavor and Quality

Stainless steel strainers provide superior pulp separation by resisting corrosion and maintaining optimal filtration, resulting in a cleaner, fresher juice flavor. Plastic strainers may retain odors and discolor over time, potentially imparting off-flavors and compromising juice quality. The durability and non-reactive nature of stainless steel ensure consistent extraction of nutrients and preserve the natural taste of fruits and vegetables.

Safety and Health Considerations

Stainless steel strainers offer superior safety and health benefits for pulp separation in juicers due to their non-toxic, non-porous surface that resists bacterial growth and corrosion. Plastic strainers may contain harmful chemicals like BPA and can degrade over time, posing health risks from chemical leaching and bacterial contamination. Choosing stainless steel ensures durability, ease of cleaning, and maintains juice purity without compromising consumer health.

Environmental Impact: Which is More Sustainable?

Stainless steel strainers offer superior sustainability compared to plastic strainers due to their durability and recyclability, reducing landfill waste over time. Plastic strainers contribute to microplastic pollution and often require more frequent replacement, increasing environmental burden. Choosing stainless steel minimizes resource consumption and promotes eco-friendly pulp separation in juicing processes.

Cost Analysis: Upfront and Long-Term Value

Stainless steel strainers incur higher upfront costs but offer superior durability, reducing replacement frequency and maintenance expenses over time. Plastic strainers provide a lower initial investment but tend to degrade faster, resulting in more frequent replacements and increased long-term costs. Evaluating total cost of ownership reveals stainless steel strainers deliver better value for frequent juicing applications.

Choosing the Best Strainer for Your Juicing Needs

Stainless steel strainers offer superior durability and resistance to staining and odors, making them ideal for heavy-duty juicing and long-term use. Plastic strainers are lightweight and cost-effective but may absorb flavors and degrade over time, which can affect pulp separation efficiency. Selecting the best strainer depends on prioritizing durability, ease of cleaning, and the type of produce you frequently juice to achieve optimal pulp separation and juice quality.

Stainless steel strainer vs plastic strainer for pulp separation Infographic

productvia.com

productvia.com