Stainless steel cavities in microwaves offer superior durability compared to painted cavities, resisting scratches, stains, and corrosion over extended use. The non-porous surface of stainless steel prevents food residue buildup and bacterial growth, enhancing hygiene and longevity. Painted cavities may chip or peel over time, compromising both appearance and structural integrity.

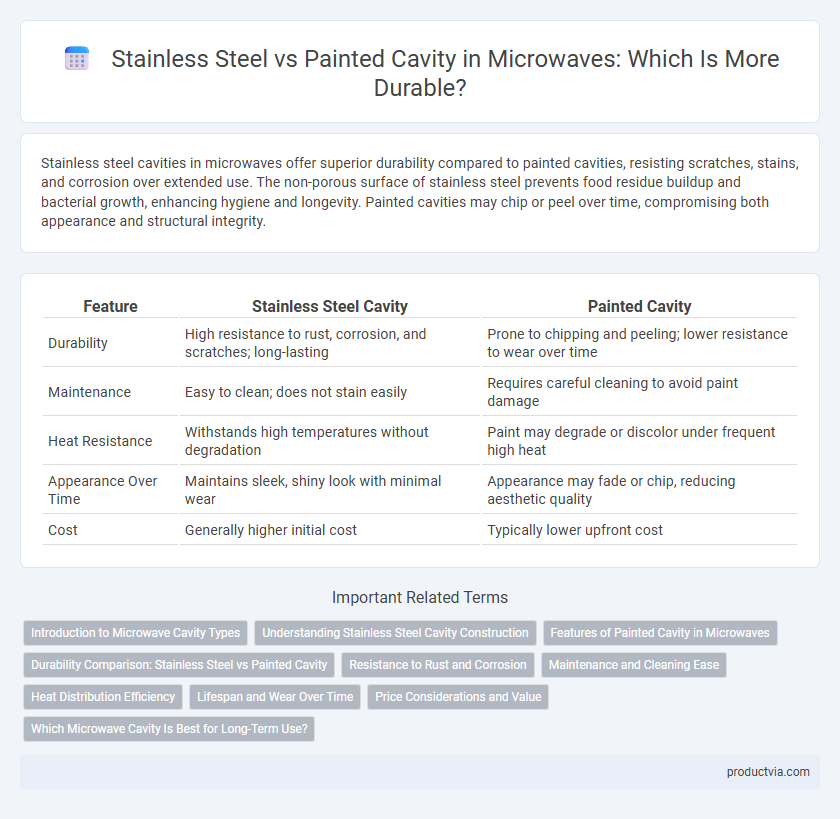

Table of Comparison

| Feature | Stainless Steel Cavity | Painted Cavity |

|---|---|---|

| Durability | High resistance to rust, corrosion, and scratches; long-lasting | Prone to chipping and peeling; lower resistance to wear over time |

| Maintenance | Easy to clean; does not stain easily | Requires careful cleaning to avoid paint damage |

| Heat Resistance | Withstands high temperatures without degradation | Paint may degrade or discolor under frequent high heat |

| Appearance Over Time | Maintains sleek, shiny look with minimal wear | Appearance may fade or chip, reducing aesthetic quality |

| Cost | Generally higher initial cost | Typically lower upfront cost |

Introduction to Microwave Cavity Types

Microwave ovens typically feature two main cavity types: stainless steel and painted cavities, each impacting durability and maintenance. Stainless steel cavities offer superior resistance to rust, stains, and corrosion, making them ideal for long-term use in high-moisture environments. Painted cavities, while more cost-effective, may chip or peel over time, reducing durability and requiring more frequent care to maintain their condition.

Understanding Stainless Steel Cavity Construction

Stainless steel cavity construction in microwaves offers superior durability due to its resistance to rust, scratches, and stains compared to painted cavities. The non-porous surface of stainless steel prevents food particles and moisture from penetrating, reducing corrosion and maintaining hygiene over time. This construction enhances microwave longevity and ensures consistent performance even under frequent use.

Features of Painted Cavity in Microwaves

Painted cavities in microwaves provide a smooth, glossy finish that resists corrosion and discoloration, enhancing long-term durability. Their non-porous surface simplifies cleaning by preventing food residue buildup and stain absorption. Compared to stainless steel, painted cavities can offer a cost-effective solution with effective protection against moisture and heat damage.

Durability Comparison: Stainless Steel vs Painted Cavity

Stainless steel cavities in microwaves offer superior durability due to their resistance to corrosion, staining, and scratching compared to painted cavities, which are more prone to chipping and discoloration over time. The non-porous surface of stainless steel simplifies cleaning and reduces the risk of bacterial buildup, enhancing longevity and hygiene. Painted cavities, while initially cost-effective, often degrade faster, leading to a shorter appliance lifespan and increased maintenance needs.

Resistance to Rust and Corrosion

Stainless steel cavities in microwaves offer superior resistance to rust and corrosion compared to painted cavities, ensuring longer-lasting durability in high-moisture environments. The non-porous surface of stainless steel prevents moisture penetration and resists staining, making it ideal for frequent use and cleaning. Painted cavities, while often more affordable, tend to chip or peel over time, increasing the risk of rust formation and reducing overall lifespan.

Maintenance and Cleaning Ease

Stainless steel cavities in microwaves offer superior durability and resist stains, making them easier to maintain compared to painted cavities that may chip or discolor over time. The non-porous surface of stainless steel prevents food residue buildup and simplifies cleaning with basic wiping, reducing the need for harsh chemicals. Painted cavities often require more careful maintenance to avoid damage, making stainless steel the preferred choice for long-term hygiene and durability.

Heat Distribution Efficiency

Stainless steel cavities in microwaves provide superior heat distribution efficiency due to their reflective surfaces, which evenly disperse microwaves and reduce hot spots. Painted cavities often degrade faster and may absorb more heat, leading to uneven cooking and compromised durability over time. The durability of stainless steel cavities also enhances consistent heat retention, contributing to reliable cooking performance and longer microwave lifespan.

Lifespan and Wear Over Time

Stainless steel cavities in microwaves offer superior durability and longevity compared to painted cavities, resisting rust, corrosion, and chipping over extended use. The non-porous surface of stainless steel prevents bacterial buildup and withstands high temperatures without degrading, while painted cavities prone to peeling and discoloration reduce the appliance's lifespan. Choosing stainless steel enhances maintenance ease and ensures consistent performance over years of frequent microwave use.

Price Considerations and Value

Stainless steel microwave cavities offer superior durability and corrosion resistance compared to painted cavities, often justifying a higher price through extended lifespan and better hygiene. Painted cavities provide a more affordable initial investment but may require more frequent replacements due to chipping and wear. Choosing stainless steel maximizes long-term value by reducing maintenance costs and preserving structural integrity, making it a cost-effective option despite upfront expenses.

Which Microwave Cavity Is Best for Long-Term Use?

Stainless steel microwave cavities offer superior durability and corrosion resistance compared to painted cavities, making them ideal for long-term use in high-humidity or heavy-use environments. Painted microwave cavities are prone to chipping, rusting, and wear over time, especially when exposed to moisture and frequent cleaning. For longevity, stainless steel cavities maintain structural integrity and hygiene better, ensuring consistent performance and easier maintenance.

Stainless Steel Cavity vs Painted Cavity for Durability Infographic

productvia.com

productvia.com