Pyrolytic ovens use high temperatures to burn off food residues, turning them into ash that is easy to wipe away, offering a thorough and chemical-free cleaning process. Catalytic ovens feature special liners that absorb and break down grease during regular cooking, reducing the need for manual cleaning but requiring periodic replacement of the liners. Choosing between pyrolytic and catalytic cleaning depends on user preferences for maintenance effort, cleaning frequency, and oven usage patterns.

Table of Comparison

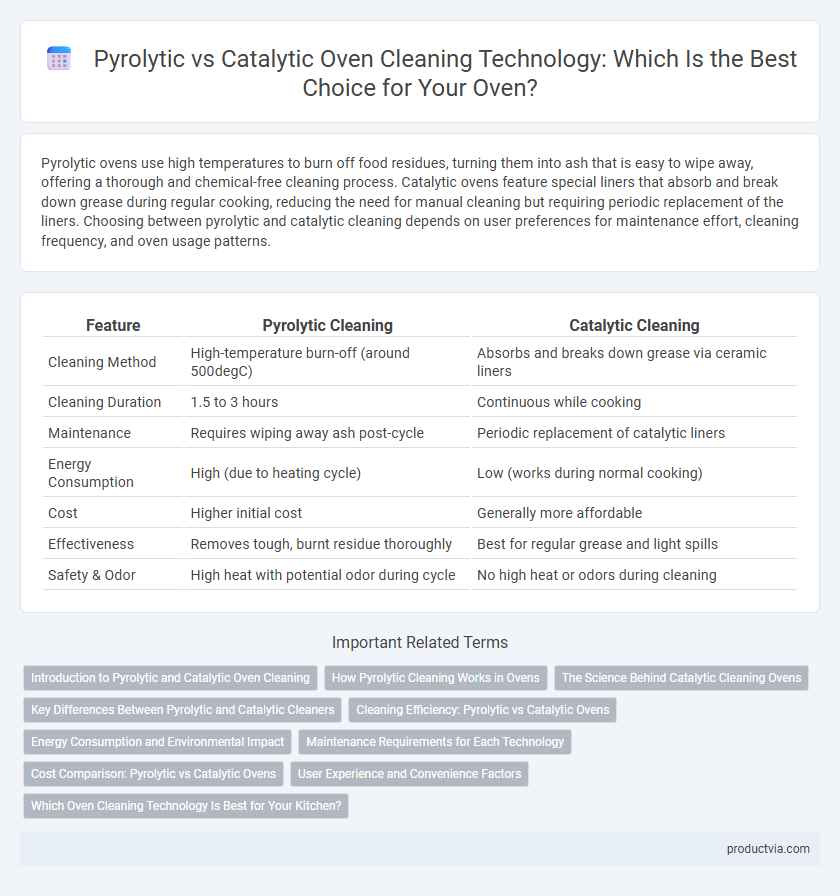

| Feature | Pyrolytic Cleaning | Catalytic Cleaning |

|---|---|---|

| Cleaning Method | High-temperature burn-off (around 500degC) | Absorbs and breaks down grease via ceramic liners |

| Cleaning Duration | 1.5 to 3 hours | Continuous while cooking |

| Maintenance | Requires wiping away ash post-cycle | Periodic replacement of catalytic liners |

| Energy Consumption | High (due to heating cycle) | Low (works during normal cooking) |

| Cost | Higher initial cost | Generally more affordable |

| Effectiveness | Removes tough, burnt residue thoroughly | Best for regular grease and light spills |

| Safety & Odor | High heat with potential odor during cycle | No high heat or odors during cleaning |

Introduction to Pyrolytic and Catalytic Oven Cleaning

Pyrolytic oven cleaning utilizes extremely high temperatures, around 500degC, to incinerate food residues and grease into ash that can be easily wiped away, offering a thorough and chemical-free cleaning process. Catalytic oven cleaning involves specially coated liners that absorb and break down grease and grime during regular cooking temperatures, reducing the need for intense cleaning cycles. Both technologies enhance oven maintenance, with pyrolytic providing a deep clean through heat and catalytic offering continuous grease absorption.

How Pyrolytic Cleaning Works in Ovens

Pyrolytic cleaning in ovens utilizes extremely high temperatures, around 500degC, to incinerate food residues and grease, turning them into ash that can be easily wiped away. This self-cleaning process relies on the oven's insulated interior to maintain heat efficiently, allowing for thorough decomposition of organic matter without the need for chemical agents. Pyrolytic ovens often feature safety locks during cleaning cycles to prevent accidental opening and exposure to intense heat.

The Science Behind Catalytic Cleaning Ovens

Catalytic cleaning ovens utilize a porous enamel coating embedded with oxidation catalysts that break down food residues at moderate temperatures between 200-250degC, transforming organic matter into ash during normal cooking cycles. This technology relies on the catalytic reaction to accelerate the decomposition of grease and grime, reducing the need for high-temperature pyrolytic cleaning cycles that can reach up to 500degC. The science behind catalytic ovens ensures efficient cleaning with lower energy consumption and less heat exposure, making it an eco-friendly and user-friendly option for maintaining oven hygiene.

Key Differences Between Pyrolytic and Catalytic Cleaners

Pyrolytic oven cleaning technology uses high temperatures of around 500degC to incinerate food residues into ash, which can be easily wiped away, while catalytic cleaners use special porous panels coated with a catalyst that oxidizes grease and food splatters at normal cooking temperatures. Pyrolytic cleaning requires a dedicated cleaning cycle lasting 1.5 to 3 hours, consuming more energy, whereas catalytic panels continuously absorb and break down grime during regular oven use without extra energy input. Maintenance for pyrolytic ovens involves removing ash residues post-cycle, while catalytic panels may need replacement every few years to maintain effectiveness.

Cleaning Efficiency: Pyrolytic vs Catalytic Ovens

Pyrolytic ovens use extremely high temperatures around 500degC to incinerate food residues into ash, offering superior cleaning efficiency by completely breaking down stubborn grease and burnt-on residues. Catalytic ovens incorporate porous catalytic liners that absorb and break down grease at moderate temperatures, allowing continuous cleaning during cooking but with less thorough removal of heavy soil compared to pyrolytic systems. Pyrolytic cleaning requires a dedicated cleaning cycle and residual ash wiping, whereas catalytic cleaning is more maintenance-free but may necessitate occasional manual cleaning for optimal performance.

Energy Consumption and Environmental Impact

Pyrolytic oven cleaning employs high temperatures around 500degC to incinerate food residues, resulting in higher energy consumption compared to catalytic cleaning, which uses lower heat and absorbent liners to break down grease during regular cooking cycles. While pyrolytic cleaning produces ash requiring manual removal, it emits fewer chemical residues, making it environmentally friendlier in terms of emissions. Catalytic cleaning reduces energy use and chemical emissions but may lose effectiveness over time, necessitating liner replacement, which contributes to waste.

Maintenance Requirements for Each Technology

Pyrolytic ovens require high-temperature self-cleaning cycles that burn off food residues into ash, reducing manual scrubbing but demanding high energy consumption and occasional drawer cleaning. Catalytic ovens feature porous liners coated with catalysts that absorb and break down grease at normal cooking temperatures, requiring less energy and more frequent replacement of the liners for effective maintenance. Regular inspection of catalytic panels is necessary to maintain performance, while pyrolytic ovens benefit from minimal manual upkeep aside from ash removal after each cycle.

Cost Comparison: Pyrolytic vs Catalytic Ovens

Pyrolytic ovens typically have higher upfront costs due to their advanced self-cleaning technology, which heats the oven to extremely high temperatures to burn off residue. Catalytic ovens, on the other hand, are generally less expensive but require more frequent manual cleaning and replacement of catalytic liners, which can increase long-term maintenance expenses. Over time, pyrolytic ovens may offer better value through reduced cleaning time and effort despite initial investment.

User Experience and Convenience Factors

Pyrolytic ovens use high temperatures around 500degC to burn off food residues, offering a hands-free, highly effective cleaning process that requires minimal user effort and no chemicals. Catalytic ovens feature porous liners coated with a catalyst that breaks down grease at normal cooking temperatures, providing continuous cleaning during regular use but needing manual intervention for thorough maintenance. Users prioritize pyrolytic technology for its convenience and time-saving benefits, while catalytic models appeal due to lower energy consumption and consistent upkeep.

Which Oven Cleaning Technology Is Best for Your Kitchen?

Pyrolytic oven cleaning uses high temperatures around 500degC to burn off food residues into ash, making it easy to wipe away, ideal for heavy-duty cleaning and convenience. Catalytic cleaning ovens feature porous liners coated with a catalyst that breaks down grease at normal cooking temperatures, offering continuous maintenance with less energy consumption. Choosing the best oven cleaning technology depends on your cooking habits and cleaning preferences, with pyrolytic models suited for infrequent but intense cleaning, while catalytic ovens provide ongoing grease control for regular use.

Pyrolytic vs Catalytic for Oven Cleaning Technology Infographic

productvia.com

productvia.com