Pyrolytic ovens use extremely high temperatures to burn off food residues, turning them into ash that can be easily wiped away, offering a thorough and time-efficient self-cleaning process. Catalytic ovens feature porous liners that absorb grease and food splatters during cooking, breaking them down at moderate oven temperatures, which requires more frequent maintenance but uses less energy. Choosing between pyrolytic and catalytic self-cleaning depends on the desired cleaning intensity and energy consumption preferences.

Table of Comparison

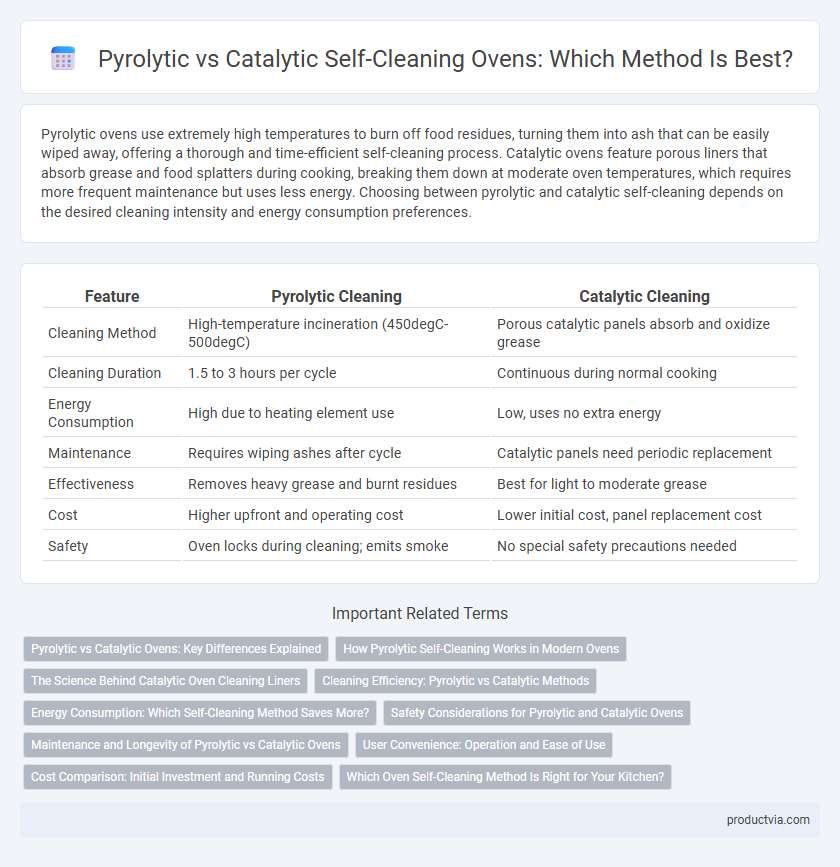

| Feature | Pyrolytic Cleaning | Catalytic Cleaning |

|---|---|---|

| Cleaning Method | High-temperature incineration (450degC-500degC) | Porous catalytic panels absorb and oxidize grease |

| Cleaning Duration | 1.5 to 3 hours per cycle | Continuous during normal cooking |

| Energy Consumption | High due to heating element use | Low, uses no extra energy |

| Maintenance | Requires wiping ashes after cycle | Catalytic panels need periodic replacement |

| Effectiveness | Removes heavy grease and burnt residues | Best for light to moderate grease |

| Cost | Higher upfront and operating cost | Lower initial cost, panel replacement cost |

| Safety | Oven locks during cleaning; emits smoke | No special safety precautions needed |

Pyrolytic vs Catalytic Ovens: Key Differences Explained

Pyrolytic ovens use extremely high temperatures, around 500degC, to incinerate food residue into ash that can be easily wiped away, providing a thorough and chemical-free cleaning process. Catalytic ovens feature special liners coated with a porous glaze that absorbs and breaks down grease and food splatters at lower temperatures during normal cooking. Pyrolytic cleaning cycles take longer but offer deeper cleaning, while catalytic ovens require regular replacement of liners for optimal performance.

How Pyrolytic Self-Cleaning Works in Modern Ovens

Pyrolytic self-cleaning ovens use extremely high temperatures, around 500degC (932degF), to incinerate food residues and grease into ash, which can be easily wiped away after the cycle completes. This method relies on robust oven insulation and heavy-duty door seals to contain heat safely within the cavity, ensuring energy efficiency and user safety. Unlike catalytic liners that absorb grease during cooking but degrade over time, pyrolytic cleaning offers a thorough, maintenance-free solution by destroying contaminants completely.

The Science Behind Catalytic Oven Cleaning Liners

Catalytic oven cleaning liners utilize a porous enamel coating embedded with catalysts that break down grease and food residues at moderate temperatures, typically between 200degC and 250degC. This process involves oxidation reactions that convert organic matter into water and carbon dioxide, reducing the need for harsh chemicals or high-temperature cycles associated with pyrolytic cleaning. The scientific efficiency of catalytic liners lies in their ability to maintain continuous cleaning during regular oven use, enhancing convenience and energy savings.

Cleaning Efficiency: Pyrolytic vs Catalytic Methods

Pyrolytic ovens reach temperatures around 500degC to incinerate food residues into ash, offering superior cleaning efficiency for heavy, baked-on grime compared to catalytic methods. Catalytic liners absorb grease and organic residues during normal cooking temperatures, requiring less energy but often needing manual intervention for tougher stains. Pyrolytic cleaning cycles typically last 1.5 to 3 hours, delivering a thorough clean, whereas catalytic methods provide continuous, moderate self-cleaning ideal for daily maintenance but less effective against stubborn buildup.

Energy Consumption: Which Self-Cleaning Method Saves More?

Pyrolytic ovens consume more energy due to high-temperature cycles reaching around 500degC to incinerate food residues, leading to intensive electricity usage during cleaning. Catalytic ovens operate at lower temperatures of approximately 200-250degC using a special lining to absorb and break down grease, resulting in significantly reduced energy consumption. Therefore, catalytic self-cleaning methods offer a more energy-efficient solution compared to pyrolytic ovens.

Safety Considerations for Pyrolytic and Catalytic Ovens

Pyrolytic ovens reach extremely high temperatures around 900degF (482degC) to burn off residues, posing risks of burns and fire hazards if safety protocols are not followed; proper ventilation is essential to avoid smoke buildup. Catalytic ovens use a coated liner to absorb and break down grease at normal cooking temperatures, minimizing the risk of high-heat burns but requiring careful maintenance to ensure effectiveness. Both methods demand adherence to manufacturer instructions and regular inspection to maintain safety standards during self-cleaning cycles.

Maintenance and Longevity of Pyrolytic vs Catalytic Ovens

Pyrolytic ovens use extremely high temperatures to burn off food residues, requiring minimal manual maintenance and offering superior longevity due to their durable construction designed to withstand intense heat cycles. Catalytic ovens contain special liners coated with a porous enamel that absorbs and breaks down grease during regular cooking temperatures, but these liners degrade over time, necessitating periodic replacement and more frequent upkeep. Overall, pyrolytic ovens typically provide longer-lasting, low-maintenance performance compared to catalytic ovens, which demand ongoing care and parts replacement to maintain efficiency.

User Convenience: Operation and Ease of Use

Pyrolytic ovens simplify cleaning by reaching extremely high temperatures that incinerate residues into ash, which can be easily wiped away, requiring minimal user effort. Catalytic ovens feature special liners that absorb and break down grease during regular cooking, reducing the need for manual cleaning but may require periodic replacement of the liners. Users seeking hands-off, thorough cleaning often prefer pyrolytic ovens for their straightforward operation, while catalytic ovens offer continuous cleaning without added steps during routine use.

Cost Comparison: Initial Investment and Running Costs

Pyrolytic ovens typically have a higher initial investment cost due to advanced heating elements and insulation, while catalytic ovens are generally more affordable upfront. Running costs for pyrolytic models can be higher because they consume more electricity during high-temperature self-clean cycles, whereas catalytic ovens use less energy but require periodic replacement of catalytic liners. Evaluating both options involves balancing the upfront cost against ongoing expenses to determine the most cost-effective choice based on usage frequency and energy efficiency.

Which Oven Self-Cleaning Method Is Right for Your Kitchen?

Pyrolytic ovens use high temperatures of around 900degF to turn food residue into ash, providing a thorough and chemical-free cleaning. Catalytic ovens feature special liners that absorb grease and burn it off during regular cooking at lower temperatures, offering convenience without lengthy cleaning cycles. Choosing between pyrolytic and catalytic self-cleaning depends on your cooking habits, cleaning preferences, and energy consumption considerations in your kitchen.

Pyrolytic vs Catalytic for self-cleaning methods Infographic

productvia.com

productvia.com