The stirring rod mechanism in a popcorn maker pet ensures kernels move constantly, preventing burning and promoting uniform heat distribution for perfectly popped corn. In contrast, a stationary base design can lead to uneven popping with more unpopped or burnt kernels due to static heat contact. Choosing a model with a stirring rod significantly enhances popping efficiency and overall snack quality.

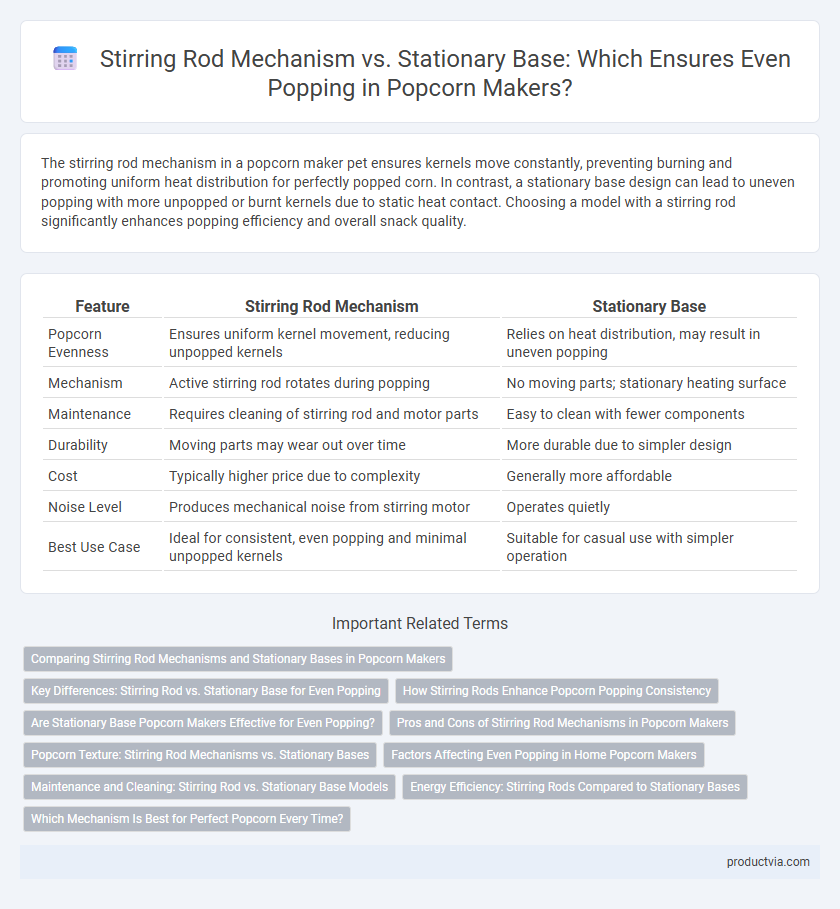

Table of Comparison

| Feature | Stirring Rod Mechanism | Stationary Base |

|---|---|---|

| Popcorn Evenness | Ensures uniform kernel movement, reducing unpopped kernels | Relies on heat distribution, may result in uneven popping |

| Mechanism | Active stirring rod rotates during popping | No moving parts; stationary heating surface |

| Maintenance | Requires cleaning of stirring rod and motor parts | Easy to clean with fewer components |

| Durability | Moving parts may wear out over time | More durable due to simpler design |

| Cost | Typically higher price due to complexity | Generally more affordable |

| Noise Level | Produces mechanical noise from stirring motor | Operates quietly |

| Best Use Case | Ideal for consistent, even popping and minimal unpopped kernels | Suitable for casual use with simpler operation |

Comparing Stirring Rod Mechanisms and Stationary Bases in Popcorn Makers

Stirring rod mechanisms in popcorn makers ensure even heat distribution by continuously moving kernels, reducing unpopped and burnt corn compared to stationary bases. Stationary bases rely on consistent heat but often result in uneven popping due to kernel clustering and hotspots. Popcorn makers with stirring rods typically deliver higher pop rates and more uniform texture, enhancing overall popping efficiency.

Key Differences: Stirring Rod vs. Stationary Base for Even Popping

The stirring rod mechanism actively rotates kernels inside the popcorn maker, ensuring consistent heat distribution and reducing unpopped kernels compared to the stationary base, which relies on static heat and can result in uneven popping. Models with stirring rods typically achieve higher pop rates and more uniform texture, as the constant agitation prevents burning and clumping. In contrast, stationary base designs are simpler but often produce clusters of burnt or partially popped kernels due to uneven exposure to heat.

How Stirring Rods Enhance Popcorn Popping Consistency

Stirring rod mechanisms in popcorn makers continuously agitate kernels, preventing clumping and ensuring even heat distribution for uniform popping. This consistent movement reduces the number of unpopped kernels compared to stationary bases, which rely solely on static heat and can cause uneven cooking. Enhanced kernel agitation from stirring rods significantly improves popping efficiency and overall popcorn quality.

Are Stationary Base Popcorn Makers Effective for Even Popping?

Stationary base popcorn makers rely on consistent heat distribution without mechanically stirring the kernels, which often leads to uneven popping and a higher number of unpopped kernels. In contrast, stirring rod mechanisms actively agitate the kernels, promoting uniform heat exposure and reducing burning or clumping. For optimal even popping, popcorn makers with stirring rod systems generally outperform stationary base models in efficiency and popped kernel yield.

Pros and Cons of Stirring Rod Mechanisms in Popcorn Makers

Stirring rod mechanisms in popcorn makers ensure even heat distribution and consistent kernel movement, reducing the risk of burning and increasing overall popping efficiency. However, these mechanisms can be prone to mechanical failure, require regular cleaning to prevent buildup, and may add noise during operation. Compared to stationary bases, stirring rods offer better kernel agitation but increase complexity and maintenance needs.

Popcorn Texture: Stirring Rod Mechanisms vs. Stationary Bases

Stirring rod mechanisms promote more uniform heat distribution by continuously moving kernels, resulting in consistently fluffy and evenly popped popcorn with minimal unpopped kernels. Stationary bases rely on static heat, often causing uneven popping that can lead to a mix of burnt and undercooked popcorn, affecting overall texture. The dynamic motion of stirring rods enhances kernel separation during popping, producing a lighter, crispier texture compared to the denser, sometimes chewy texture from stationary base models.

Factors Affecting Even Popping in Home Popcorn Makers

The stirring rod mechanism in popcorn makers ensures more consistent heat distribution by continuously moving kernels, reducing the chance of burning and unpopped kernels compared to a stationary base. Factors affecting even popping include the design of the stirring mechanism, the speed and consistency of kernel agitation, and the uniformity of heat application throughout the popping chamber. Efficient stirring combined with stable heat sources promotes higher popping rates and reduces kernel waste in home popcorn makers.

Maintenance and Cleaning: Stirring Rod vs. Stationary Base Models

Stirring rod mechanisms in popcorn makers require regular cleaning to prevent buildup of oil and kernels, which can affect performance and hygiene. Stationary base models have fewer moving parts, making them easier to clean and maintain with minimal disassembly. Proper maintenance of stirring rods ensures even popping and extends the lifespan of the appliance, while stationary base units offer convenience for users prioritizing low-maintenance operation.

Energy Efficiency: Stirring Rods Compared to Stationary Bases

Stirring rod mechanisms in popcorn makers promote more uniform heat distribution by continuously agitating kernels, resulting in consistent popping and reduced energy waste compared to stationary bases. This dynamic stirring minimizes the need for prolonged cooking times and overheating, enhancing overall energy efficiency. Stationary bases often require higher energy input to prevent scorching and uneven pops, making stirring rod systems a more sustainable choice for energy-conscious consumers.

Which Mechanism Is Best for Perfect Popcorn Every Time?

A stirring rod mechanism ensures even heat distribution and continuous agitation of kernels, preventing burning and resulting in consistently fluffy popcorn. In contrast, a stationary base relies on manual shaking or heat conduction alone, which can cause uneven popping and increase the number of unpopped kernels. For perfect popcorn every time, the stirring rod mechanism is superior due to its ability to maintain uniform kernel movement and optimal popping conditions.

Stirring rod mechanism vs stationary base for even popping Infographic

productvia.com

productvia.com