Inverter compressors in refrigerators adjust their speed based on cooling demand, significantly improving energy efficiency compared to conventional compressors that operate at a fixed speed. This variable speed operation reduces electricity consumption, minimizes temperature fluctuations, and extends the compressor's lifespan. As a result, refrigerators with inverter compressors offer quieter performance and lower utility bills while maintaining optimal food preservation.

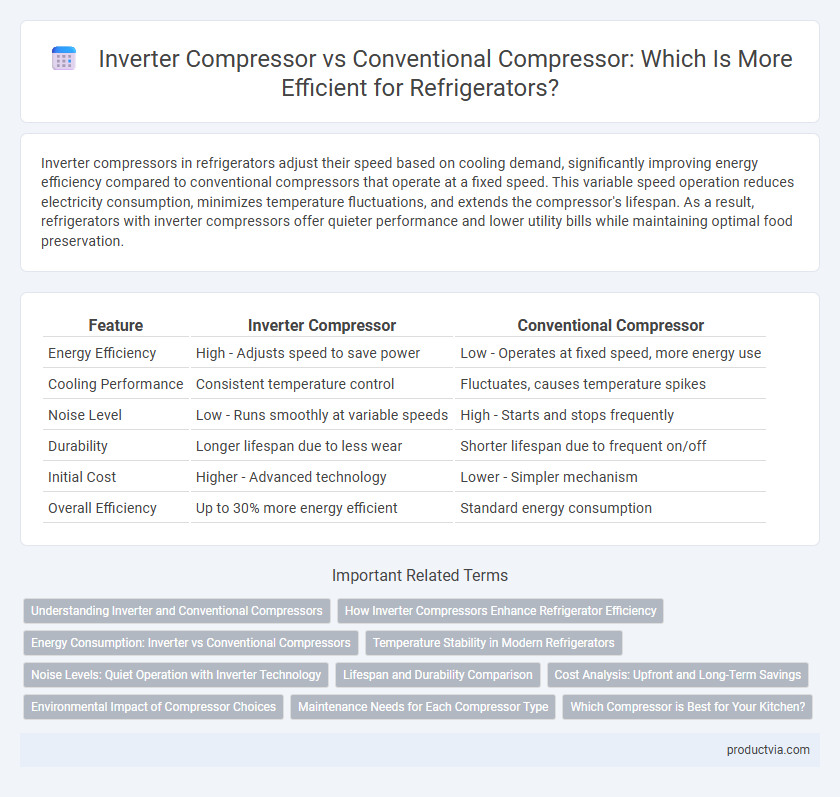

Table of Comparison

| Feature | Inverter Compressor | Conventional Compressor |

|---|---|---|

| Energy Efficiency | High - Adjusts speed to save power | Low - Operates at fixed speed, more energy use |

| Cooling Performance | Consistent temperature control | Fluctuates, causes temperature spikes |

| Noise Level | Low - Runs smoothly at variable speeds | High - Starts and stops frequently |

| Durability | Longer lifespan due to less wear | Shorter lifespan due to frequent on/off |

| Initial Cost | Higher - Advanced technology | Lower - Simpler mechanism |

| Overall Efficiency | Up to 30% more energy efficient | Standard energy consumption |

Understanding Inverter and Conventional Compressors

Inverter compressors continuously regulate their speed to maintain the optimal temperature, resulting in significant energy savings and quieter operation compared to conventional compressors, which operate at a fixed speed and frequently turn on and off. This variable speed technology allows inverter compressors to adapt to cooling demands more precisely, reducing wear and extending the lifespan of the refrigerator. Conventional compressors consume more electricity due to power surges at startup and less efficient temperature control, making inverter compressors the preferred choice for energy-efficient refrigeration.

How Inverter Compressors Enhance Refrigerator Efficiency

Inverter compressors optimize refrigerator efficiency by adjusting their speed according to cooling demand, reducing energy consumption compared to the fixed-speed operation of conventional compressors. This variable-speed technology minimizes power usage during temperature maintenance, leading to significant electricity savings and less wear on the compressor. Enhanced temperature control also prolongs food freshness while reducing noise levels, making inverter compressors a superior choice for energy-efficient refrigeration.

Energy Consumption: Inverter vs Conventional Compressors

Inverter compressors in refrigerators regulate motor speed to optimize energy consumption, resulting in up to 30-50% lower electricity use compared to conventional compressors, which operate at a constant speed and cycle on and off. This steady adjustment minimizes power fluctuations and reduces wear, enhancing overall energy efficiency and longevity. Studies indicate that inverter technology significantly decreases peak energy demand, contributing to lower utility bills and reduced environmental impact.

Temperature Stability in Modern Refrigerators

Inverter compressors in modern refrigerators provide superior temperature stability by continuously adjusting cooling power to maintain consistent internal conditions, reducing fluctuations that are common in conventional compressor systems. Conventional compressors operate with an on/off cycle that leads to wider temperature variations, which can affect food preservation quality. The precise modulation of inverter compressors enhances energy efficiency and ensures optimal freshness by maintaining steady temperatures.

Noise Levels: Quiet Operation with Inverter Technology

Inverter compressors in refrigerators operate at variable speeds, significantly reducing noise levels compared to conventional compressors that run at a fixed speed and cycle on and off frequently. This quiet operation enhances user comfort, making inverter-equipped refrigerators ideal for open-concept living spaces and quiet environments. By minimizing frequent starts and stops, inverter technology also contributes to more stable temperature control and energy-efficient performance.

Lifespan and Durability Comparison

Inverter compressors in refrigerators offer enhanced lifespan and durability compared to conventional compressors due to their ability to operate at variable speeds, reducing wear and tear by avoiding frequent starts and stops. Conventional compressors run at a fixed speed, causing more mechanical stress and shorter operational life. Studies show inverter compressors can last up to 2-3 times longer, providing greater reliability and energy efficiency over time.

Cost Analysis: Upfront and Long-Term Savings

Inverter compressors in refrigerators typically have higher upfront costs compared to conventional compressors due to advanced technology and precision manufacturing. However, inverter compressors offer significant long-term savings by consuming 30-50% less energy, reducing electricity bills and extending appliance lifespan. Over the lifespan of the refrigerator, the lower operational costs of inverter compressors often offset the initial investment, making them more cost-effective despite the higher purchase price.

Environmental Impact of Compressor Choices

Inverter compressors in refrigerators significantly reduce energy consumption by adjusting motor speed to actual cooling needs, leading to lower greenhouse gas emissions compared to conventional compressors, which operate at a constant speed and consume more electricity. This energy efficiency translates into a smaller carbon footprint, aligning with global efforts to reduce environmental impact. Choosing an inverter compressor refrigerator promotes sustainable energy use and decreases reliance on fossil fuels used for electricity generation.

Maintenance Needs for Each Compressor Type

Inverter compressors require less frequent maintenance due to their ability to operate at variable speeds, reducing wear and tear on components. Conventional compressors run at a fixed speed, leading to more frequent on-off cycles that increase mechanical stress and maintenance needs. Choosing an inverter compressor enhances refrigerator efficiency by minimizing downtime and servicing costs over its lifespan.

Which Compressor is Best for Your Kitchen?

Inverter compressors adjust their speed based on cooling demand, resulting in significant energy savings and quieter operation compared to conventional compressors, which cycle on and off at full power. For kitchens where energy efficiency, noise reduction, and consistent temperature control are priorities, inverter compressors are the optimal choice. Conventional compressors may be suitable for budget-conscious buyers but lack the efficiency and longevity benefits of inverter technology.

Inverter compressor vs Conventional compressor for refrigerator efficiency Infographic

productvia.com

productvia.com