Inverter compressors in refrigerator motors provide precise temperature control and energy efficiency by adjusting their speed according to cooling demand, reducing power consumption and noise levels. Conventional compressors operate at a fixed speed, cycling on and off, which leads to higher energy usage and fluctuating temperatures inside the refrigerator. Choosing an inverter compressor enhances durability, consistent cooling performance, and lowers electricity bills compared to traditional compressor models.

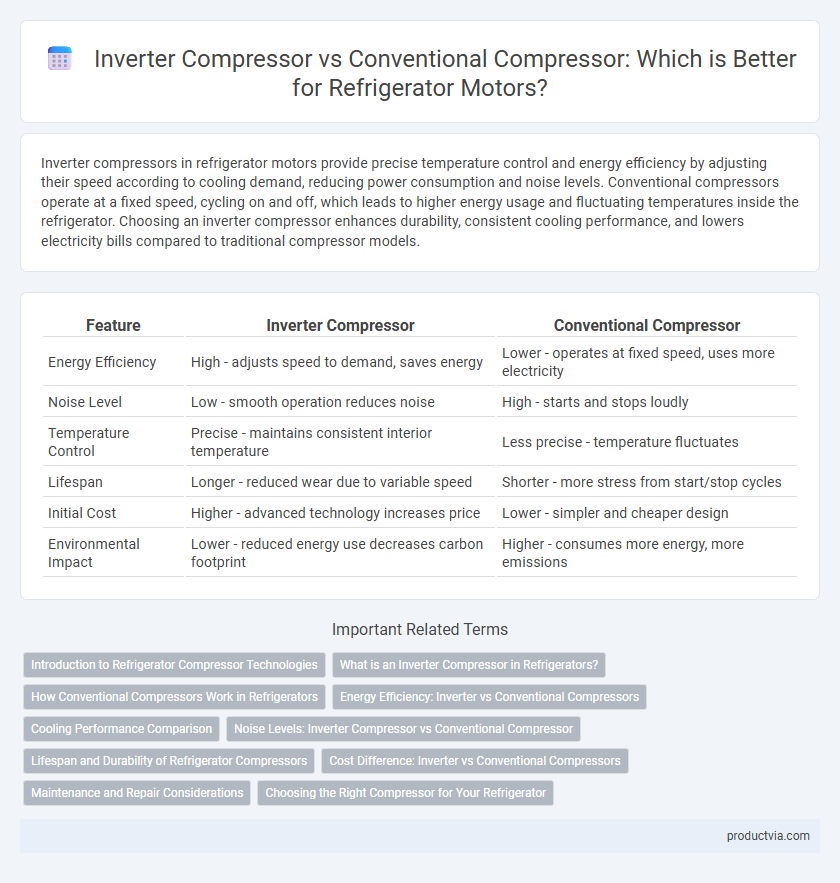

Table of Comparison

| Feature | Inverter Compressor | Conventional Compressor |

|---|---|---|

| Energy Efficiency | High - adjusts speed to demand, saves energy | Lower - operates at fixed speed, uses more electricity |

| Noise Level | Low - smooth operation reduces noise | High - starts and stops loudly |

| Temperature Control | Precise - maintains consistent interior temperature | Less precise - temperature fluctuates |

| Lifespan | Longer - reduced wear due to variable speed | Shorter - more stress from start/stop cycles |

| Initial Cost | Higher - advanced technology increases price | Lower - simpler and cheaper design |

| Environmental Impact | Lower - reduced energy use decreases carbon footprint | Higher - consumes more energy, more emissions |

Introduction to Refrigerator Compressor Technologies

Inverter compressors in refrigerator motors adjust their speed according to cooling demand, resulting in energy-efficient operation and quieter performance compared to conventional compressors that operate at fixed speeds. The modulation capability of inverter technology reduces power consumption by approximately 30%-50%, extending appliance lifespan through reduced wear and tear. Conventional compressors, while simpler and less expensive initially, tend to produce more noise and consume more energy due to their binary start-stop operation.

What is an Inverter Compressor in Refrigerators?

An inverter compressor in refrigerators uses variable speed technology to regulate cooling based on the internal temperature, enhancing energy efficiency and reducing noise. Unlike conventional compressors that operate at fixed speeds, inverter compressors adjust motor speed continuously for precise temperature control and prolonged appliance lifespan. This technology offers significant energy savings and improved performance compared to traditional compressor systems.

How Conventional Compressors Work in Refrigerators

Conventional compressors in refrigerators operate using a fixed-speed motor that cycles on and off to maintain the desired temperature, leading to higher energy consumption and temperature fluctuations. These compressors rely on a single-speed operation, causing frequent stops and starts that increase wear and noise levels. The lack of variable speed control results in less efficient cooling performance compared to inverter compressors, impacting overall energy efficiency.

Energy Efficiency: Inverter vs Conventional Compressors

Inverter compressors in refrigerators adjust their speed according to cooling demand, resulting in significant energy savings compared to conventional compressors that operate at a fixed speed and frequently switch on and off. This variable speed operation reduces energy consumption by up to 30-50%, enhancing overall energy efficiency. Consumers benefit from lower electricity bills and reduced environmental impact with inverter technology.

Cooling Performance Comparison

Inverter compressors in refrigerators deliver superior cooling performance by adjusting motor speed to match cooling demand, ensuring consistent temperature control and energy efficiency. Conventional compressors operate at a fixed speed, causing frequent start-stop cycles that lead to temperature fluctuations and higher energy consumption. This variable speed technology in inverter compressors results in faster cooling, quieter operation, and improved food preservation compared to traditional compressor models.

Noise Levels: Inverter Compressor vs Conventional Compressor

Inverter compressors operate with variable speed technology, significantly reducing noise levels by adjusting motor speed according to cooling demand, resulting in quieter operation compared to conventional compressors that run at a constant speed and generate louder, more frequent noise fluctuations. The smoother, low-frequency sound profile of inverter compressors minimizes disturbances in kitchen environments, enhancing user comfort. Conventional compressors produce higher noise peaks during start-up and shut-down cycles, making inverter models preferable for noise-sensitive households.

Lifespan and Durability of Refrigerator Compressors

Inverter compressors in refrigerators operate at variable speeds, reducing wear and tear compared to conventional compressors that run at a fixed speed, resulting in extended lifespan and enhanced durability. These compressors adapt to cooling demands, minimizing stress on components and improving energy efficiency over time. Research indicates inverter compressors can last up to 25-30% longer than traditional models, making them a reliable choice for long-term use.

Cost Difference: Inverter vs Conventional Compressors

Inverter compressors generally have a higher upfront cost compared to conventional compressors due to advanced technology and energy-saving features. Conventional compressors are typically less expensive initially but may lead to higher electricity bills over time because they operate at a constant speed without energy modulation. The long-term savings on electricity expenses with inverter compressors often offset the initial price difference, making them a cost-effective option for energy-conscious consumers.

Maintenance and Repair Considerations

Inverter compressors for refrigerator motors offer reduced maintenance needs due to their variable speed operation, which minimizes wear and tear compared to conventional compressors that operate at a fixed speed and often experience more frequent mechanical strain. Repair considerations for inverter compressors can be more complex and costly because of their advanced electronics and control systems, while conventional compressors typically have simpler designs making repairs more straightforward and less expensive. Choosing between the two depends on balancing long-term maintenance savings with potential repair costs and available technical expertise.

Choosing the Right Compressor for Your Refrigerator

Inverter compressors in refrigerators offer variable speed operation, leading to energy efficiency and quieter performance compared to conventional compressors that run at a fixed speed. Choosing the right compressor depends on factors like energy consumption, cooling consistency, and budget, with inverter models typically reducing electricity bills and providing better temperature control. For households prioritizing long-term savings and quieter operation, inverter compressors are ideal, whereas conventional compressors may suit those with lower upfront cost preferences.

Inverter Compressor vs Conventional Compressor for Refrigerator Motors Infographic

productvia.com

productvia.com