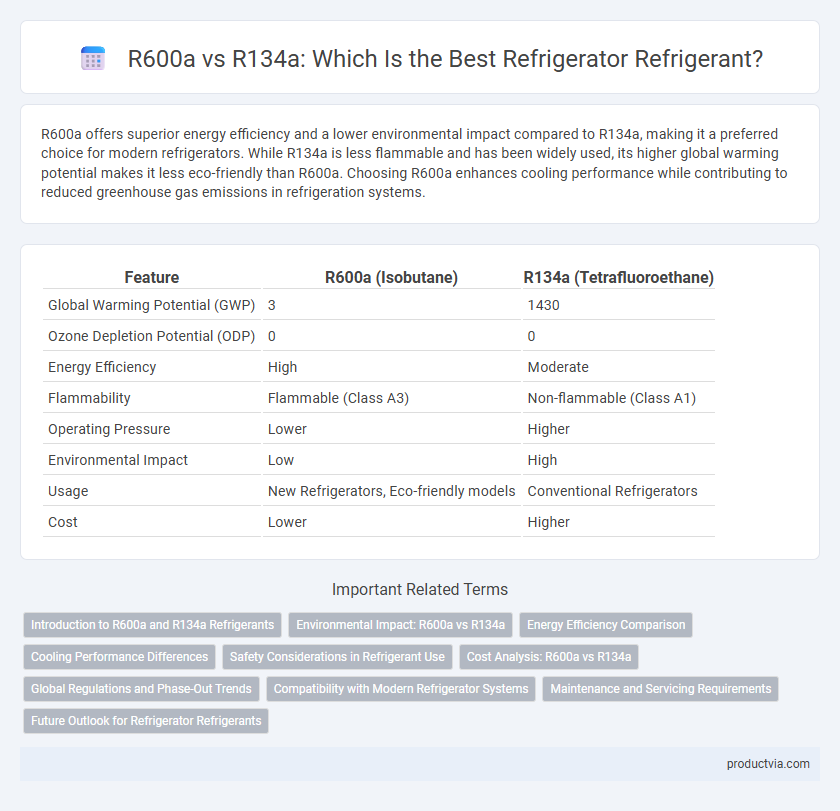

R600a offers superior energy efficiency and a lower environmental impact compared to R134a, making it a preferred choice for modern refrigerators. While R134a is less flammable and has been widely used, its higher global warming potential makes it less eco-friendly than R600a. Choosing R600a enhances cooling performance while contributing to reduced greenhouse gas emissions in refrigeration systems.

Table of Comparison

| Feature | R600a (Isobutane) | R134a (Tetrafluoroethane) |

|---|---|---|

| Global Warming Potential (GWP) | 3 | 1430 |

| Ozone Depletion Potential (ODP) | 0 | 0 |

| Energy Efficiency | High | Moderate |

| Flammability | Flammable (Class A3) | Non-flammable (Class A1) |

| Operating Pressure | Lower | Higher |

| Environmental Impact | Low | High |

| Usage | New Refrigerators, Eco-friendly models | Conventional Refrigerators |

| Cost | Lower | Higher |

Introduction to R600a and R134a Refrigerants

R600a, also known as isobutane, is a natural hydrocarbon refrigerant widely used in modern refrigerators due to its low Global Warming Potential (GWP) and high energy efficiency. In contrast, R134a is a hydrofluorocarbon (HFC) refrigerant commonly used in older refrigeration systems, characterized by higher GWP and ozone-friendly properties but less environmental sustainability compared to R600a. The shift from R134a to R600a reflects the refrigeration industry's commitment to reducing greenhouse gas emissions while maintaining optimal cooling performance.

Environmental Impact: R600a vs R134a

R600a (isobutane) exhibits significantly lower global warming potential (GWP) of approximately 3 compared to R134a's GWP of 1430, making R600a far more environmentally friendly. R600a is a natural refrigerant with zero ozone depletion potential (ODP), whereas R134a is a hydrofluorocarbon (HFC) that contributes to greenhouse gas emissions and has a moderate ODP. The shift to R600a in refrigerator manufacturing reduces carbon footprint and complies better with international environmental regulations targeting climate change mitigation.

Energy Efficiency Comparison

R600a refrigerant offers superior energy efficiency compared to R134a, reducing electricity consumption by approximately 10-15% in refrigerators due to its lower global warming potential and enhanced thermodynamic properties. R600a's higher latent heat and better heat transfer capabilities enable compressors to operate less frequently, increasing overall system efficiency. Conversely, R134a, while widely used, tends to consume more energy and has a higher environmental impact, making R600a a more eco-friendly and cost-effective choice for modern refrigeration appliances.

Cooling Performance Differences

R600a offers superior energy efficiency and better cooling performance compared to R134a due to its lower global warming potential and higher latent heat of vaporization. Refrigerators using R600a generally achieve faster cooling cycles and maintain more stable internal temperatures, enhancing overall appliance reliability. In contrast, R134a provides adequate cooling but requires higher compression ratios, resulting in increased energy consumption and reduced environmental sustainability.

Safety Considerations in Refrigerant Use

R600a is a hydrocarbon refrigerant with low toxicity and excellent environmental properties but is highly flammable, requiring careful handling and proper ventilation during refrigerator maintenance. R134a is a hydrofluorocarbon refrigerant with low flammability and moderate toxicity, offering safer use in terms of fire risk but contributing more significantly to global warming. Choosing between R600a and R134a for refrigerators depends on balancing flammability hazards against environmental impact and ensuring compliance with safety standards.

Cost Analysis: R600a vs R134a

R600a refrigerant offers lower operational costs compared to R134a due to its higher energy efficiency and lower power consumption in refrigerators. While the initial cost of R600a units may be slightly higher, long-term savings on electricity bills result in a favorable total cost of ownership. In contrast, R134a systems often incur higher maintenance and energy expenses, increasing overall lifecycle costs despite lower upfront prices.

Global Regulations and Phase-Out Trends

R600a, a hydrocarbon refrigerant with low global warming potential (GWP) under 4, is increasingly favored in domestic refrigerators due to stricter international regulations like the Kigali Amendment targeting high-GWP refrigerants. R134a, with a GWP of 1430, faces phase-out mandates in many regions including the EU and North America, prompting manufacturers to shift toward environmentally friendly alternatives such as R600a. The transition supports regulatory compliance and sustainability goals while maintaining energy efficiency and cooling performance in refrigeration systems.

Compatibility with Modern Refrigerator Systems

R600a refrigerant offers superior compatibility with modern refrigerator systems due to its higher energy efficiency and lower environmental impact compared to R134a. Unlike R134a, R600a is a natural hydrocarbon refrigerant that integrates seamlessly with advanced compressor technologies, reducing overall power consumption. Manufacturers increasingly prefer R600a for its ability to meet stringent global regulations on greenhouse gas emissions while maintaining optimal cooling performance.

Maintenance and Servicing Requirements

R600a refrigerant offers lower maintenance demands compared to R134a due to its natural properties, resulting in fewer leaks and reduced compressor wear. Servicing R600a systems requires specialized training because of its flammability, whereas R134a systems are safer to handle but may need more frequent checks for leaks and refrigerant top-ups. Technicians must use appropriate tools and safety measures tailored to each refrigerant's characteristics to ensure efficient and safe servicing.

Future Outlook for Refrigerator Refrigerants

R600a is increasingly favored over R134a in refrigerator refrigerants due to its lower global warming potential (GWP) of 3 compared to R134a's GWP of 1430, aligning with stricter environmental regulations. The adoption of R600a supports energy-efficient cooling technologies, reducing carbon footprints and operational costs. Advances in hydrocarbon refrigerant safety and performance are expected to drive wider integration in residential and commercial refrigeration sectors by 2030.

R600a vs R134a for Refrigerator Refrigerants Infographic

productvia.com

productvia.com