Non-stick coating on sandwich makers offers easy cleaning and prevents food from sticking, reducing maintenance time significantly. Stainless steel plates are more durable and resistant to scratches but require more thorough cleaning to avoid residue buildup. Choosing between the two depends on prioritizing convenience or long-term durability in maintenance.

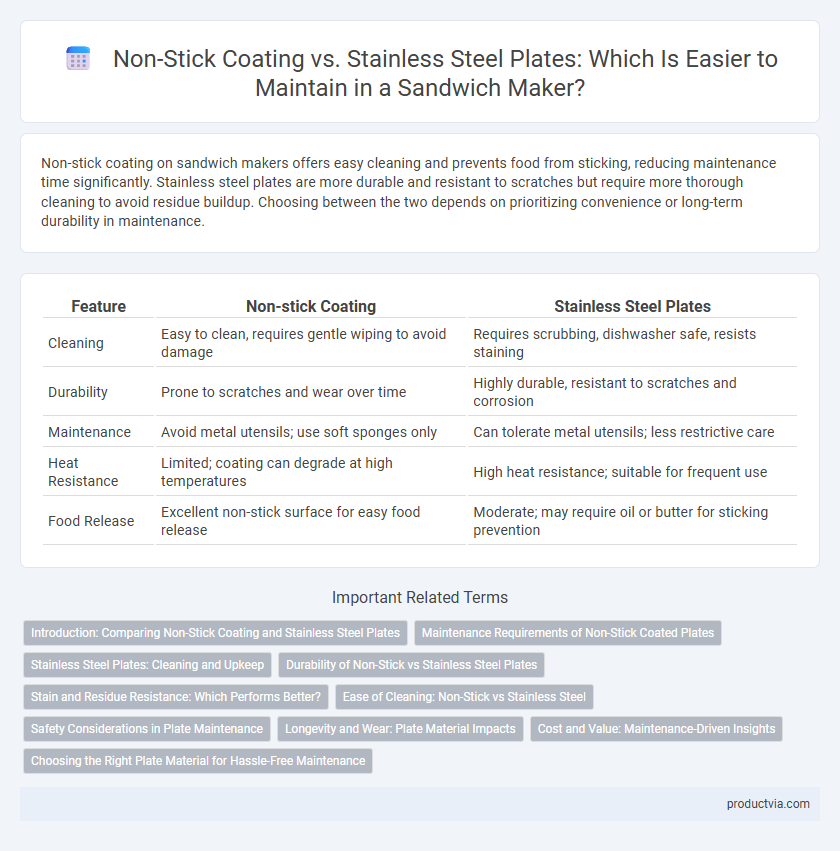

Table of Comparison

| Feature | Non-stick Coating | Stainless Steel Plates |

|---|---|---|

| Cleaning | Easy to clean, requires gentle wiping to avoid damage | Requires scrubbing, dishwasher safe, resists staining |

| Durability | Prone to scratches and wear over time | Highly durable, resistant to scratches and corrosion |

| Maintenance | Avoid metal utensils; use soft sponges only | Can tolerate metal utensils; less restrictive care |

| Heat Resistance | Limited; coating can degrade at high temperatures | High heat resistance; suitable for frequent use |

| Food Release | Excellent non-stick surface for easy food release | Moderate; may require oil or butter for sticking prevention |

Introduction: Comparing Non-Stick Coating and Stainless Steel Plates

Non-stick coating in sandwich makers offers easy cleaning and requires minimal maintenance due to its resistance to food sticking and less need for scrubbing. Stainless steel plates provide greater durability and can withstand abrasive cleaning methods, making them more resilient over time but may require more effort to remove stuck food particles. Choosing between the two depends on the balance between convenience in maintenance and long-term plate durability.

Maintenance Requirements of Non-Stick Coated Plates

Non-stick coated plates in sandwich makers require minimal maintenance due to their smooth surface, which prevents food from sticking and allows easy cleaning with a soft cloth or sponge. Avoid using metal utensils or abrasive cleaners to preserve the coating's integrity and prolong its lifespan. Regular wiping after each use ensures optimal non-stick performance and prevents residue buildup.

Stainless Steel Plates: Cleaning and Upkeep

Stainless steel plates in sandwich makers offer durability and resistance to scratches, making them easier to maintain over time. Cleaning involves wiping with a damp cloth or using mild detergent to remove food residue without damaging the surface. Regular upkeep prevents rust and retains the plate's smooth finish, ensuring consistent cooking performance.

Durability of Non-Stick vs Stainless Steel Plates

Non-stick coatings offer easy cleanup and resist food sticking, but their durability can decline over time due to scratching or peeling. Stainless steel plates provide superior durability and withstand heavy use without degrading, though they may require more effort to clean. Choosing between the two depends on balancing maintenance convenience with long-term plate resilience.

Stain and Residue Resistance: Which Performs Better?

Non-stick coating on sandwich makers offers superior stain and residue resistance compared to stainless steel plates, making cleaning easier and maintenance less time-consuming. Stainless steel plates, while durable, tend to retain stains and food residues, requiring more vigorous scrubbing and specialized cleaners to maintain their appearance. For users prioritizing hassle-free upkeep and consistent cleanliness, non-stick surfaces generally outperform stainless steel in resisting stains and food buildup.

Ease of Cleaning: Non-Stick vs Stainless Steel

Non-stick coating on sandwich makers offers superior ease of cleaning by preventing food from sticking, reducing the need for vigorous scrubbing and minimizing residue buildup. In contrast, stainless steel plates require more effort to clean, as food particles can adhere to the surface, often necessitating soaking or the use of abrasive scrubbers. Maintaining non-stick surfaces involves gentle cleaning to preserve their coating, while stainless steel plates withstand harsher cleaning methods, making them durable but more labor-intensive to maintain.

Safety Considerations in Plate Maintenance

Non-stick coating on sandwich makers requires gentle cleaning with soft sponges to avoid damaging the surface, ensuring safe use without harmful chemical exposure. Stainless steel plates offer durability and can withstand scrubbers, reducing the risk of scratches that harbor bacteria but need thorough drying to prevent rust. Choosing the right plate material influences maintenance safety by balancing ease of cleaning and long-term hygiene.

Longevity and Wear: Plate Material Impacts

Non-stick coating plates offer easy maintenance due to their resistance to food sticking and quick cleaning, but they tend to wear out faster and may require replacement within a few years. Stainless steel plates provide superior longevity and durability, resisting scratches and corrosion, making them ideal for heavy use despite needing more effort to clean. Plate material significantly impacts the sandwich maker's lifespan, with stainless steel ensuring extended durability while non-stick coatings prioritize user convenience.

Cost and Value: Maintenance-Driven Insights

Non-stick coating sandwich makers require less effort and cost for cleaning, as food residues rarely stick to the surface, reducing the need for abrasive scrubbing or specialized cleaners. Stainless steel plates, while more durable and resistant to scratches, often demand more intensive maintenance, including thorough drying to prevent rust and potential use of metal-safe detergents, which can increase upkeep expenses. In terms of value, non-stick plates offer cost-effective maintenance with consistent performance, whereas stainless steel plates may incur higher long-term maintenance costs despite their robustness.

Choosing the Right Plate Material for Hassle-Free Maintenance

Non-stick coating plates offer easy cleanup by preventing food from sticking, requiring only a simple wipe with a damp cloth after use. Stainless steel plates, while more durable and resistant to scratches, need thorough cleaning and occasional scrubbing to remove stuck-on residues, increasing maintenance time. Choosing non-stick plates prioritizes hassle-free maintenance with minimal effort, whereas stainless steel may suit users valuing durability despite more intensive care.

Non-stick coating vs Stainless steel plates for maintenance Infographic

productvia.com

productvia.com