Die-cast metal housing in stand mixers offers superior durability, enhanced heat dissipation, and a premium, sturdy feel compared to plastic housing. Plastic housing models are generally lighter and more affordable but can be less robust and prone to cracking under heavy use. Choosing metal housing ensures longevity and stability during vigorous mixing tasks.

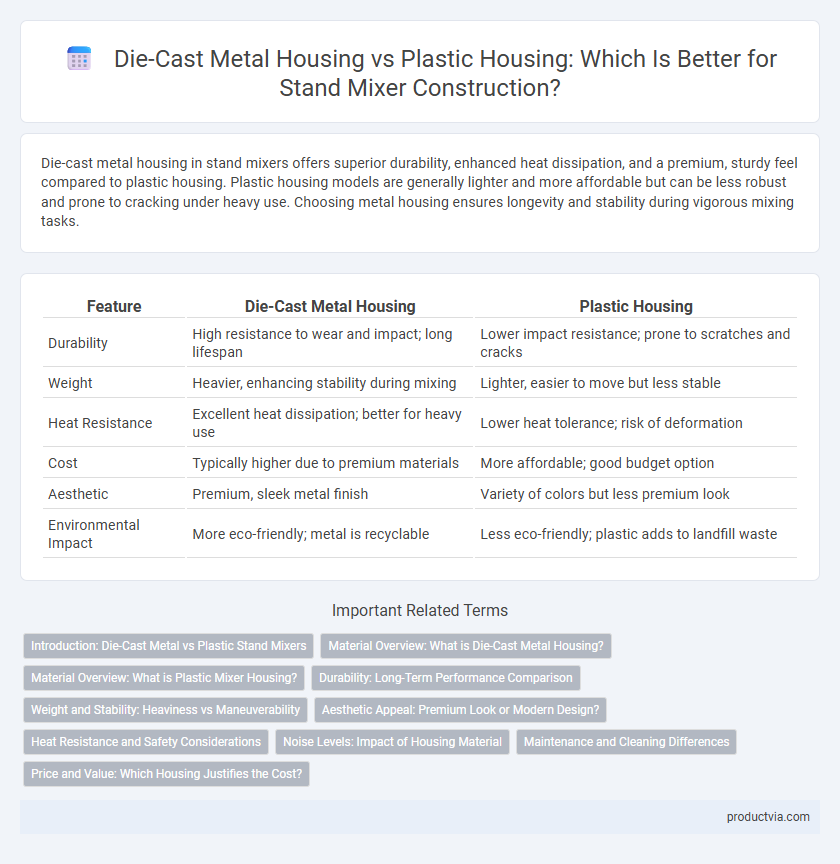

Table of Comparison

| Feature | Die-Cast Metal Housing | Plastic Housing |

|---|---|---|

| Durability | High resistance to wear and impact; long lifespan | Lower impact resistance; prone to scratches and cracks |

| Weight | Heavier, enhancing stability during mixing | Lighter, easier to move but less stable |

| Heat Resistance | Excellent heat dissipation; better for heavy use | Lower heat tolerance; risk of deformation |

| Cost | Typically higher due to premium materials | More affordable; good budget option |

| Aesthetic | Premium, sleek metal finish | Variety of colors but less premium look |

| Environmental Impact | More eco-friendly; metal is recyclable | Less eco-friendly; plastic adds to landfill waste |

Introduction: Die-Cast Metal vs Plastic Stand Mixers

Die-cast metal housing in stand mixers offers superior durability, stability, and heat resistance compared to plastic housing, making it ideal for frequent or heavy-duty use. Plastic housing tends to be lighter and more affordable but may lack the robustness needed for intensive mixing tasks and can degrade over time. Choosing between die-cast metal and plastic affects the mixer's longevity, performance, and overall user experience.

Material Overview: What is Die-Cast Metal Housing?

Die-cast metal housing for stand mixers is produced by forcing molten metal, typically aluminum or zinc, into high-precision steel molds, resulting in a durable and rigid exterior that enhances the mixer's stability and longevity. This material offers superior heat dissipation and impact resistance compared to plastic housing, which is typically made from injection-molded polypropylene or ABS polymers, providing a lighter but less robust shell. The dense, solid nature of die-cast metal housing significantly reduces vibration and noise during operation, making it a preferred choice for high-performance stand mixers.

Material Overview: What is Plastic Mixer Housing?

Plastic mixer housing in stand mixers is typically made from high-grade, durable polymers such as ABS or polycarbonate, offering lightweight and cost-effective construction. Unlike die-cast metal housing, plastic provides enhanced resistance to corrosion and impact, while enabling more versatile design shapes and color options. However, it may lack the same level of heat dissipation and structural rigidity found in die-cast metal enclosures.

Durability: Long-Term Performance Comparison

Die-cast metal housing in stand mixers offers superior durability and long-term performance compared to plastic housing, resisting wear, heat, and mechanical stress more effectively. Metal enclosures provide enhanced structural integrity, minimizing vibrations and extending the mixer's lifespan under frequent use. Plastic housing, while lightweight and cost-effective, is more prone to cracking and warping over time, reducing the appliance's overall durability.

Weight and Stability: Heaviness vs Maneuverability

Die-cast metal housing in stand mixers offers superior weight and stability, reducing vibrations during heavy mixing tasks for enhanced performance. Plastic housing provides a lighter, more maneuverable design, which is easier to lift and store but may sacrifice some stability under high-torque operations. Choosing between die-cast metal and plastic housing depends on prioritizing durability and steadiness versus portability and ease of handling.

Aesthetic Appeal: Premium Look or Modern Design?

Die-cast metal housing offers a premium look with a sleek, durable finish that enhances the stand mixer's aesthetic appeal, making it a centerpiece in any kitchen. Plastic housing provides a modern design with versatile color options and lightweight construction, appealing to contemporary tastes and ease of handling. Both materials balance form and function, but metal exudes a timeless elegance, while plastic emphasizes trendy style and ergonomic convenience.

Heat Resistance and Safety Considerations

Die-cast metal housing in stand mixers offers superior heat resistance, enhancing durability during prolonged mixing tasks and preventing deformation under high motor temperatures. Plastic housing, while lighter and more cost-effective, may soften or warp when exposed to heat, potentially compromising safety and structural integrity. Metal construction provides better protection against overheating risks, ensuring safer operation in demanding kitchen environments.

Noise Levels: Impact of Housing Material

Die-cast metal housing in stand mixers significantly reduces noise levels by dampening vibrations more effectively than plastic housing. The dense metal structure absorbs and minimizes operational sounds, resulting in quieter performance during mixing tasks. Plastic housings tend to amplify noise due to their lighter, less rigid composition, leading to increased sound output.

Maintenance and Cleaning Differences

Die-cast metal housing offers superior durability and resists staining and odor retention, making it easier to maintain and clean compared to plastic housing. Plastic housings are more prone to scratches and discoloration over time, requiring more frequent and careful cleaning to avoid damage. Metal surfaces typically withstand harsh cleaning agents better, ensuring long-term hygiene and a polished appearance.

Price and Value: Which Housing Justifies the Cost?

Die-cast metal housing in stand mixers offers superior durability and stability, often reflected in a higher price point but delivering long-term value through enhanced performance and longevity. Plastic housing models are more affordable upfront and lightweight, appealing to budget-conscious users, yet they may lack the robustness needed for heavy-duty mixing tasks, potentially leading to higher replacement costs over time. When justifying cost, die-cast metal housing stands out for serious home bakers seeking investment in a reliable appliance, while plastic housing suits occasional use with lower immediate financial commitment.

Die-cast metal housing vs Plastic housing for stand mixer build Infographic

productvia.com

productvia.com