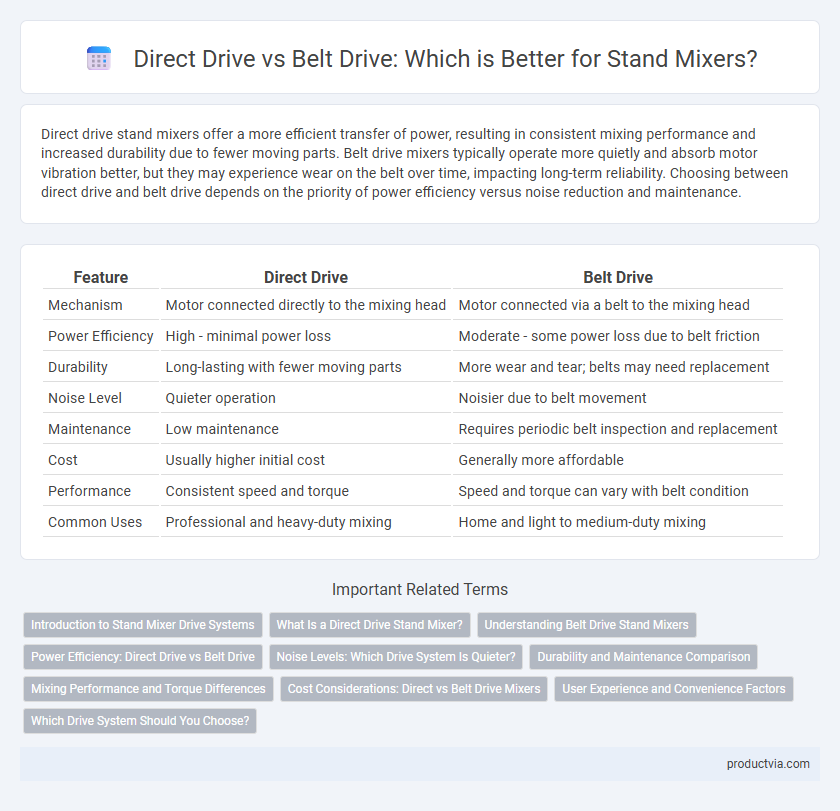

Direct drive stand mixers offer a more efficient transfer of power, resulting in consistent mixing performance and increased durability due to fewer moving parts. Belt drive mixers typically operate more quietly and absorb motor vibration better, but they may experience wear on the belt over time, impacting long-term reliability. Choosing between direct drive and belt drive depends on the priority of power efficiency versus noise reduction and maintenance.

Table of Comparison

| Feature | Direct Drive | Belt Drive |

|---|---|---|

| Mechanism | Motor connected directly to the mixing head | Motor connected via a belt to the mixing head |

| Power Efficiency | High - minimal power loss | Moderate - some power loss due to belt friction |

| Durability | Long-lasting with fewer moving parts | More wear and tear; belts may need replacement |

| Noise Level | Quieter operation | Noisier due to belt movement |

| Maintenance | Low maintenance | Requires periodic belt inspection and replacement |

| Cost | Usually higher initial cost | Generally more affordable |

| Performance | Consistent speed and torque | Speed and torque can vary with belt condition |

| Common Uses | Professional and heavy-duty mixing | Home and light to medium-duty mixing |

Introduction to Stand Mixer Drive Systems

Stand mixer drive systems primarily consist of direct drive and belt drive mechanisms, each impacting performance and durability differently. Direct drive mixers connect the motor directly to the mixing attachment, offering more power and efficiency with less energy loss. Belt drive mixers use a belt to transfer motor power to the mixing head, providing quieter operation but potentially less torque and increased maintenance.

What Is a Direct Drive Stand Mixer?

A direct drive stand mixer features a motor that is directly connected to the mixing mechanism, resulting in more efficient power transfer and reduced energy loss compared to belt drive models. This design typically offers greater durability and consistent mixing speeds, making it ideal for handling heavy doughs and long mixing sessions. Users benefit from quieter operation and lower maintenance since there are fewer moving parts prone to wear and tear.

Understanding Belt Drive Stand Mixers

Belt drive stand mixers use a flexible belt to transfer power from the motor to the mixing head, resulting in quieter operation and reduced motor strain. This design often leads to slower speeds but increased durability and smoother mixing, especially for heavy doughs and prolonged use. Understanding these features helps users choose a stand mixer that balances noise levels, power efficiency, and longevity based on their baking needs.

Power Efficiency: Direct Drive vs Belt Drive

Direct drive stand mixers offer superior power efficiency by transferring motor energy directly to the mixing mechanism, minimizing energy loss and enhancing performance. Belt drive mixers experience power loss due to friction and slippage within the belt system, reducing overall efficiency and torque delivery. Consumers seeking optimal energy use and consistent mixing power often prefer direct drive systems for their reliability and effectiveness.

Noise Levels: Which Drive System Is Quieter?

Direct drive stand mixers generally produce less noise because the motor is attached directly to the mixing mechanism, eliminating vibrations caused by belt movement. Belt drive mixers tend to generate more operational noise due to slippage and tension variations in the belt. For quieter kitchen environments, direct drive systems are preferred due to their efficient and stable power transmission.

Durability and Maintenance Comparison

Direct drive stand mixers typically offer superior durability due to the motor being directly connected to the mixing mechanism, reducing wear on parts and minimizing maintenance needs. Belt drive mixers often require more frequent belt replacements and adjustments, which can increase maintenance over time and potentially reduce overall longevity. Choosing a direct drive model can lead to longer-lasting performance and less frequent repair costs, making it ideal for heavy or frequent use.

Mixing Performance and Torque Differences

Direct drive stand mixers deliver superior mixing performance and higher torque by connecting the motor directly to the mixing mechanism, ensuring efficient power transfer and consistent speed under heavy loads. Belt drive models offer smoother operation and reduced motor noise but may experience slight power loss and reduced torque during intensive mixing tasks. Understanding these torque differences is crucial for selecting a stand mixer tailored to heavy-duty baking or casual home use.

Cost Considerations: Direct vs Belt Drive Mixers

Direct drive stand mixers generally have higher upfront costs due to their robust motor design, which offers greater durability and power efficiency. Belt drive mixers tend to be more affordable initially but may incur additional maintenance expenses over time as belts wear out and require replacement. Budget-conscious buyers should weigh the long-term value of direct drive models against the lower initial price of belt drive mixers when making their decision.

User Experience and Convenience Factors

Direct drive stand mixers deliver more consistent power and quieter operation, enhancing user experience during prolonged mixing tasks. Belt drive models tend to be more affordable but may produce more noise and require occasional belt maintenance, impacting convenience. Choosing between them depends on the importance of durability and noise level for the user's kitchen routine.

Which Drive System Should You Choose?

Direct drive stand mixers offer more efficient power transfer and typically provide stronger, more consistent torque, making them ideal for heavy-duty mixing tasks and frequent use. Belt drive stand mixers tend to operate more quietly and gently, reducing motor wear and vibration, which is suitable for lighter baking or occasional use. Choose a direct drive system for durability and high performance or a belt drive for quieter operation and smoother handling of delicate ingredients.

Direct drive vs Belt drive for stand mixers Infographic

productvia.com

productvia.com