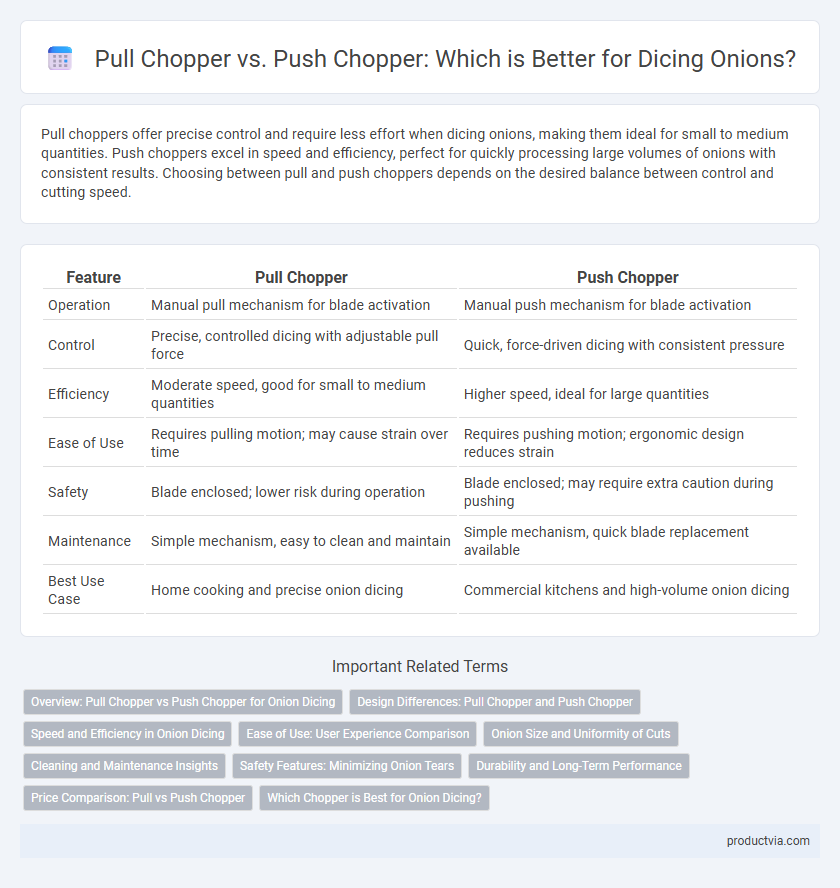

Pull choppers offer precise control and require less effort when dicing onions, making them ideal for small to medium quantities. Push choppers excel in speed and efficiency, perfect for quickly processing large volumes of onions with consistent results. Choosing between pull and push choppers depends on the desired balance between control and cutting speed.

Table of Comparison

| Feature | Pull Chopper | Push Chopper |

|---|---|---|

| Operation | Manual pull mechanism for blade activation | Manual push mechanism for blade activation |

| Control | Precise, controlled dicing with adjustable pull force | Quick, force-driven dicing with consistent pressure |

| Efficiency | Moderate speed, good for small to medium quantities | Higher speed, ideal for large quantities |

| Ease of Use | Requires pulling motion; may cause strain over time | Requires pushing motion; ergonomic design reduces strain |

| Safety | Blade enclosed; lower risk during operation | Blade enclosed; may require extra caution during pushing |

| Maintenance | Simple mechanism, easy to clean and maintain | Simple mechanism, quick blade replacement available |

| Best Use Case | Home cooking and precise onion dicing | Commercial kitchens and high-volume onion dicing |

Overview: Pull Chopper vs Push Chopper for Onion Dicing

Pull choppers use a manual pulling mechanism to rotate blades, offering precise control and less effort when dicing onions. Push choppers rely on a downward force that pushes blades through onions, making them faster but sometimes less accurate in uniformity. Choosing between pull and push choppers depends on the desired balance between speed and precision in onion dicing tasks.

Design Differences: Pull Chopper and Push Chopper

Pull choppers feature a cord mechanism that activates rotating blades when pulled, providing precise control and reducing hand fatigue during onion dicing. Push choppers utilize a downward force applied directly to the lid, engaging the blades to dice onions quickly with minimal effort. Design-wise, pull choppers often offer adjustable blade speeds for finer cuts, while push choppers emphasize simplicity and compact form factors for ease of use and storage.

Speed and Efficiency in Onion Dicing

Pull choppers deliver faster onion dicing by utilizing a sharp blade that swiftly slices through layers with minimal resistance, increasing overall efficiency. Push choppers, while offering more control, tend to slow down the process due to the force required to push the onion through the blades. For high-volume kitchen environments, pull choppers optimize speed and reduce manual effort, making them the preferred choice for rapid onion preparation.

Ease of Use: User Experience Comparison

Push choppers offer greater ease of use for onion dicing due to their simple downward motion that requires less wrist strength and coordination, reducing fatigue during repetitive tasks. Pull choppers demand a pulling action that can be less intuitive and may require more effort for consistent, even cuts. For users prioritizing speed and minimal strain, push choppers typically deliver a more ergonomic and user-friendly experience.

Onion Size and Uniformity of Cuts

Pull choppers provide greater control over onion size and uniformity of cuts by allowing users to adjust the force and speed of each pull, resulting in consistent dices ideal for recipes requiring precise onion pieces. Push choppers often produce uneven cuts due to their fixed motion and speed, making them less reliable for achieving uniform onion sizes. For finely diced onions, pull choppers ensure better texture and cooking consistency by delivering evenly sized pieces every time.

Cleaning and Maintenance Insights

Pull choppers feature detachable blades and wide-access compartments, making cleaning simpler and reducing residue buildup after onion dicing. Push choppers often involve more fixed parts and tighter crevices, which can trap onion fibers and require meticulous disassembly for thorough maintenance. Selecting a pull chopper can streamline hygiene routines and extend the device's lifespan due to easier cleaning processes.

Safety Features: Minimizing Onion Tears

Pull choppers reduce onion tears by keeping hands away from sharp blades during dicing, minimizing direct contact with irritants. Push choppers include safety guards that prevent fingers from slipping, but may still expose users to onion juices upon blade contact. Both designs prioritize safety, but pull choppers often provide a more effective barrier against tear-inducing compounds.

Durability and Long-Term Performance

Pull choppers typically feature robust stainless steel blades and reinforced mechanisms, ensuring superior durability and consistent long-term performance for onion dicing tasks. Push choppers, while often more compact, may suffer from quicker wear on cutting components due to increased friction and force applied during operation. Choosing a pull chopper can result in reduced maintenance costs and prolonged efficiency in commercial or frequent kitchen use.

Price Comparison: Pull vs Push Chopper

Pull choppers for onion dicing generally come at a lower price point due to their simpler design and fewer moving parts. Push choppers tend to be more expensive, reflecting their enhanced efficiency and ease of use. When comparing costs, consumers should weigh initial investment against long-term durability and chopping precision.

Which Chopper is Best for Onion Dicing?

Pull choppers offer precise control and consistent chopping for onions, making them ideal for achieving fine, uniform dice without bruising. Push choppers excel in speed and ease of use but may produce less even cuts and cause slight onion cell damage, resulting in more release of juices. For the best onion dicing results, pull choppers provide superior accuracy and texture preservation, ensuring cleaner cuts and reduced onion odor.

Pull Chopper vs Push Chopper for Onion Dicing Infographic

productvia.com

productvia.com