Analog temperature control in deep fryer pets offers straightforward adjustments but may lack the accuracy needed for precise cooking temperatures. Digital temperature control provides enhanced precision with exact temperature settings, ensuring consistent and optimal frying results for pet food. Choosing digital control allows for better regulation, minimizing the risk of overheating or undercooking.

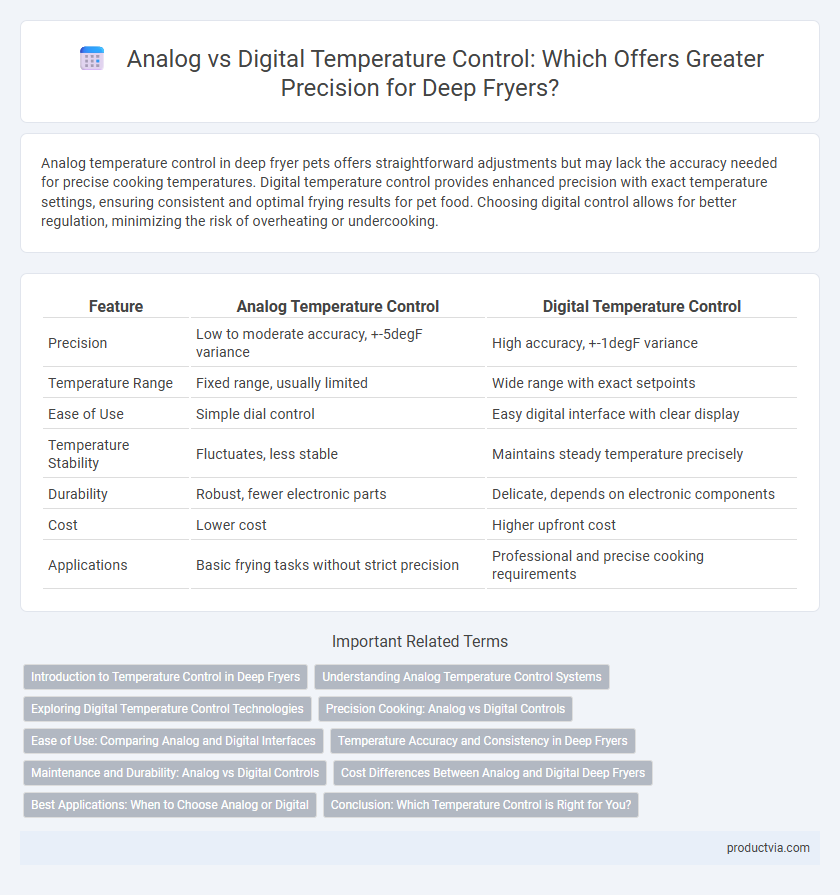

Table of Comparison

| Feature | Analog Temperature Control | Digital Temperature Control |

|---|---|---|

| Precision | Low to moderate accuracy, +-5degF variance | High accuracy, +-1degF variance |

| Temperature Range | Fixed range, usually limited | Wide range with exact setpoints |

| Ease of Use | Simple dial control | Easy digital interface with clear display |

| Temperature Stability | Fluctuates, less stable | Maintains steady temperature precisely |

| Durability | Robust, fewer electronic parts | Delicate, depends on electronic components |

| Cost | Lower cost | Higher upfront cost |

| Applications | Basic frying tasks without strict precision | Professional and precise cooking requirements |

Introduction to Temperature Control in Deep Fryers

Analog temperature control in deep fryers uses a mechanical thermostat to regulate heat, offering straightforward and cost-effective operation but with limited precision and slower response times. Digital temperature control employs electronic sensors and microprocessors to maintain exact temperatures, ensuring consistent frying results and enhanced energy efficiency. Precise temperature control is crucial for optimal food texture, flavor, and safety in commercial and home deep frying applications.

Understanding Analog Temperature Control Systems

Analog temperature control systems in deep fryers use continuous voltage or current signals to regulate heating elements, providing smooth temperature adjustments based on real-time feedback from thermocouples or thermistors. These systems offer simple, reliable control with minimal electronic complexity, allowing operators to fine-tune cooking temperatures manually within a defined range. However, analog controls may lack the precise accuracy and programmable consistency found in digital counterparts, making them less ideal for applications requiring exact temperature stability.

Exploring Digital Temperature Control Technologies

Digital temperature control technologies offer superior precision compared to analog systems by utilizing advanced microprocessors and sensors to maintain consistent oil temperatures within +-1degF. These controls enable real-time temperature monitoring and automated adjustments, reducing thermal fluctuations that can affect frying quality. The integration of programmable settings and digital displays enhances user accuracy and consistency, optimizing cooking performance and product safety in commercial deep fryers.

Precision Cooking: Analog vs Digital Controls

Analog temperature control in deep fryers relies on mechanical thermostats that provide less precise temperature regulation, often resulting in fluctuations of several degrees. Digital temperature control systems utilize electronic sensors and microprocessors to maintain exact temperatures within +-1degF, enhancing cooking consistency and reducing oil degradation. Precision cooking with digital controls ensures optimal frying results by maintaining stable heat, critical for achieving perfect texture and flavor.

Ease of Use: Comparing Analog and Digital Interfaces

Analog temperature control in deep fryers offers simplicity with straightforward knobs, allowing users to quickly set desired heat levels without navigating complex menus. Digital temperature control provides precise adjustment through touchscreen or button interfaces, enabling exact temperature settings and enhanced repeatability. The digital interface often includes additional features like timers and preset modes, improving usability for users seeking accuracy and convenience.

Temperature Accuracy and Consistency in Deep Fryers

Analog temperature controls in deep fryers often rely on mechanical thermostats, resulting in temperature fluctuations of +-5degF to +-10degF, which can affect frying consistency and food quality. Digital temperature controls utilize precise sensors and microprocessors to maintain temperature accuracy within +-1degF to +-2degF, ensuring consistent heat for optimal frying results. This enhanced precision reduces oil degradation and improves cooking performance, making digital controls the preferred choice for professional deep frying applications.

Maintenance and Durability: Analog vs Digital Controls

Analog temperature controls in deep fryers offer straightforward maintenance due to their simple mechanical parts, but they may require frequent calibration to maintain accuracy over time. Digital temperature controls provide precise temperature management with minimal recalibration, enhancing durability through advanced circuitry that often includes self-diagnostic features. The choice between analog and digital controls impacts long-term reliability and upkeep costs, with digital systems generally favored for consistent performance and reduced maintenance workloads.

Cost Differences Between Analog and Digital Deep Fryers

Analog deep fryers typically cost less upfront due to simpler mechanical thermostats, making them a budget-friendly option for basic frying needs. Digital deep fryers, equipped with advanced microchip controls, offer precise temperature regulation but come with higher purchase prices reflecting their enhanced technology. Choice depends on balancing cost sensitivity against the need for temperature accuracy and consistency in cooking outcomes.

Best Applications: When to Choose Analog or Digital

Analog temperature control in deep fryers excels in simple, budget-friendly settings where consistent heat is sufficient, making it ideal for small restaurants or home kitchens with less demand for precision. Digital temperature control offers superior accuracy and programmable settings, best suited for commercial kitchens or food establishments requiring precise temperature management and repeatability. Choosing digital controls optimizes cooking consistency and energy efficiency in high-volume frying applications.

Conclusion: Which Temperature Control is Right for You?

Analog temperature control in deep fryers offers simplicity and ease of use, making it suitable for those who prefer straightforward operation and consistent performance. Digital temperature control provides precise temperature adjustments and enhanced accuracy, ideal for professional chefs and users requiring exact cooking conditions. Choosing between analog and digital depends on your need for precision versus user-friendly functionality in your frying process.

Analog temperature control vs Digital temperature control for precision Infographic

productvia.com

productvia.com