Immersion element fryers provide more consistent heat distribution by directly submerging the heating element into the oil, ensuring rapid and even heating ideal for pet-safe cooking applications. Tube-style fryers rely on external heating tubes that transfer heat through metal surfaces, which can result in uneven temperature zones and longer heat-up times. Choosing an immersion element fryer enhances safety and efficiency by maintaining stable oil temperatures crucial for frying pet food without burning or undercooking.

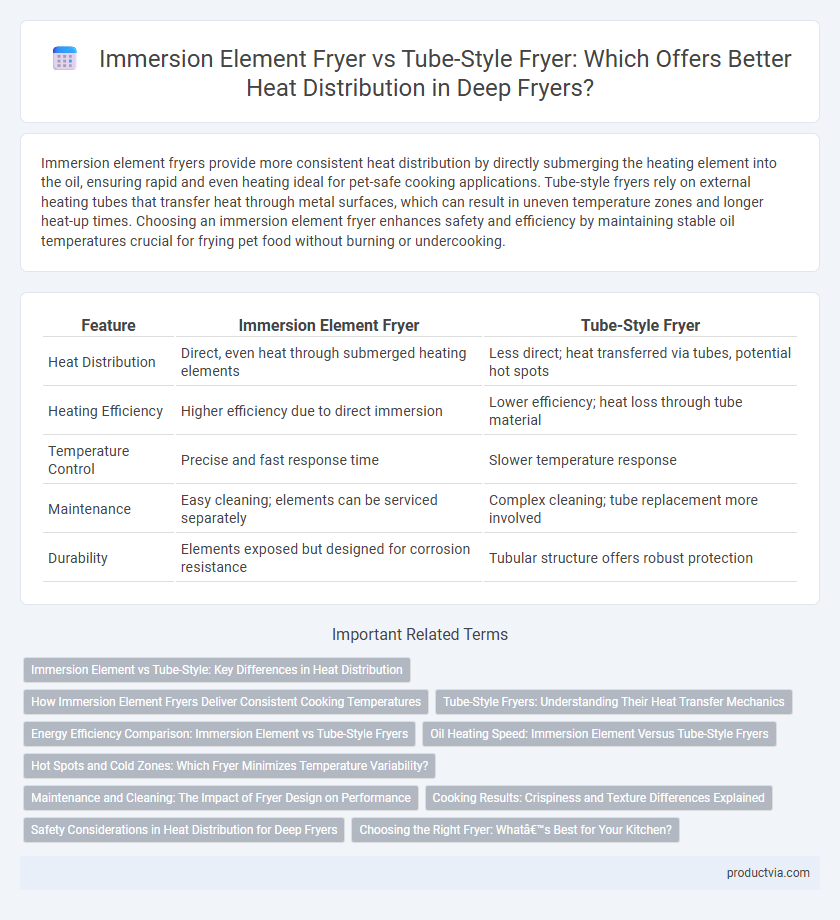

Table of Comparison

| Feature | Immersion Element Fryer | Tube-Style Fryer |

|---|---|---|

| Heat Distribution | Direct, even heat through submerged heating elements | Less direct; heat transferred via tubes, potential hot spots |

| Heating Efficiency | Higher efficiency due to direct immersion | Lower efficiency; heat loss through tube material |

| Temperature Control | Precise and fast response time | Slower temperature response |

| Maintenance | Easy cleaning; elements can be serviced separately | Complex cleaning; tube replacement more involved |

| Durability | Elements exposed but designed for corrosion resistance | Tubular structure offers robust protection |

Immersion Element vs Tube-Style: Key Differences in Heat Distribution

Immersion element fryers provide direct contact between the heating element and oil, ensuring faster and more uniform heat distribution compared to tube-style fryers. Tube-style fryers transfer heat through metal tubes submerged in oil, which can create hotspots and slower response times during temperature adjustments. This direct immersion in oil makes immersion element fryers more energy-efficient and ideal for consistent cooking results in commercial kitchens.

How Immersion Element Fryers Deliver Consistent Cooking Temperatures

Immersion element fryers deliver consistent cooking temperatures by directly submerging heating elements into the oil, ensuring rapid and uniform heat transfer. This design minimizes temperature fluctuations often found in tube-style fryers, where heat passes through metal tubes before reaching the oil. Consistent heat distribution in immersion fryers enhances cooking efficiency and results in evenly fried food with improved texture and flavor.

Tube-Style Fryers: Understanding Their Heat Transfer Mechanics

Tube-style fryers utilize heat transfer tubes submerged in oil, which provide consistent and efficient heat distribution through conduction and convection. These fryers achieve rapid heating by circulating oil around the heated tubes, ensuring even temperature maintenance crucial for uniform cooking. Their design minimizes hotspots and improves thermal efficiency compared to immersion element fryers, enhancing product quality and energy savings.

Energy Efficiency Comparison: Immersion Element vs Tube-Style Fryers

Immersion element fryers provide direct heat transfer by submerging heating elements in oil, resulting in faster heat-up times and improved energy efficiency compared to tube-style fryers, which rely on indirect heating through metal tubes. The efficient heat distribution of immersion elements minimizes energy loss and reduces overall oil degradation, lowering operational costs. Tube-style fryers often consume more energy due to slower heat transfer and less uniform heat distribution, making immersion element fryers the preferred choice for energy-conscious commercial kitchens.

Oil Heating Speed: Immersion Element Versus Tube-Style Fryers

Immersion element fryers feature heating elements directly submerged in oil, providing faster and more uniform oil heating compared to tube-style fryers, where heat transfers through tubes surrounded by oil. This direct contact in immersion heaters results in quicker heat-up times, improving cooking efficiency and reducing energy consumption. Tube-style fryers often exhibit slower oil heating due to indirect heat transfer, leading to less consistent temperature control during frying.

Hot Spots and Cold Zones: Which Fryer Minimizes Temperature Variability?

Immersion element fryers provide more uniform heat distribution by surrounding the oil with heating elements, which significantly reduces hot spots and cold zones compared to tube-style fryers. Tube-style fryers often create uneven temperature zones due to their external heating tubes, resulting in greater temperature variability that can affect cooking consistency. Consequently, immersion element fryers minimize temperature fluctuations, ensuring more consistent frying results and food quality.

Maintenance and Cleaning: The Impact of Fryer Design on Performance

Immersion element fryers feature heating elements submerged directly in oil, promoting rapid and even heat distribution but requiring frequent cleaning to prevent buildup and maintain efficiency. Tube-style fryers house heating tubes external to the oil, which can simplify maintenance by reducing direct oil exposure yet may result in uneven heating and longer warm-up times. Proper fryer design influences routine maintenance, cleaning efficiency, and overall fryer performance, impacting operational costs and food quality.

Cooking Results: Crispiness and Texture Differences Explained

Immersion element fryers provide direct contact between the heating element and the oil, resulting in faster heat recovery and more consistent temperature control, which enhances crispiness and produces a uniform texture in fried foods. Tube-style fryers rely on indirect heat transfer through tubes, often leading to slower heat recovery and uneven heat distribution, potentially causing variations in crispiness and less consistent texture. The efficient heat distribution of immersion elements is preferred for achieving optimal golden-brown crust and superior crunch in commercial frying operations.

Safety Considerations in Heat Distribution for Deep Fryers

Immersion element fryers provide more uniform heat distribution by directly immersing heating elements in the oil, reducing hotspots and minimizing the risk of oil overheating and fires. Tube-style fryers rely on external heating tubes, which can create inconsistent heat zones leading to higher chances of localized overheating and potential safety hazards. Proper heat distribution in immersion element fryers enhances operational safety by maintaining stable oil temperatures and preventing dangerous heat spikes.

Choosing the Right Fryer: What’s Best for Your Kitchen?

Immersion element fryers offer superior heat distribution by directly submerging heating elements into the oil, resulting in faster and more even cooking temperatures. Tube-style fryers use external heating tubes, which can cause uneven heat zones and slower recovery times, potentially impacting food quality and energy efficiency. Selecting the right fryer depends on kitchen volume, consistency requirements, and energy consumption, with immersion element fryers favored for high-demand, precise heat control environments.

Immersion element fryer vs Tube-style fryer for heat distribution Infographic

productvia.com

productvia.com