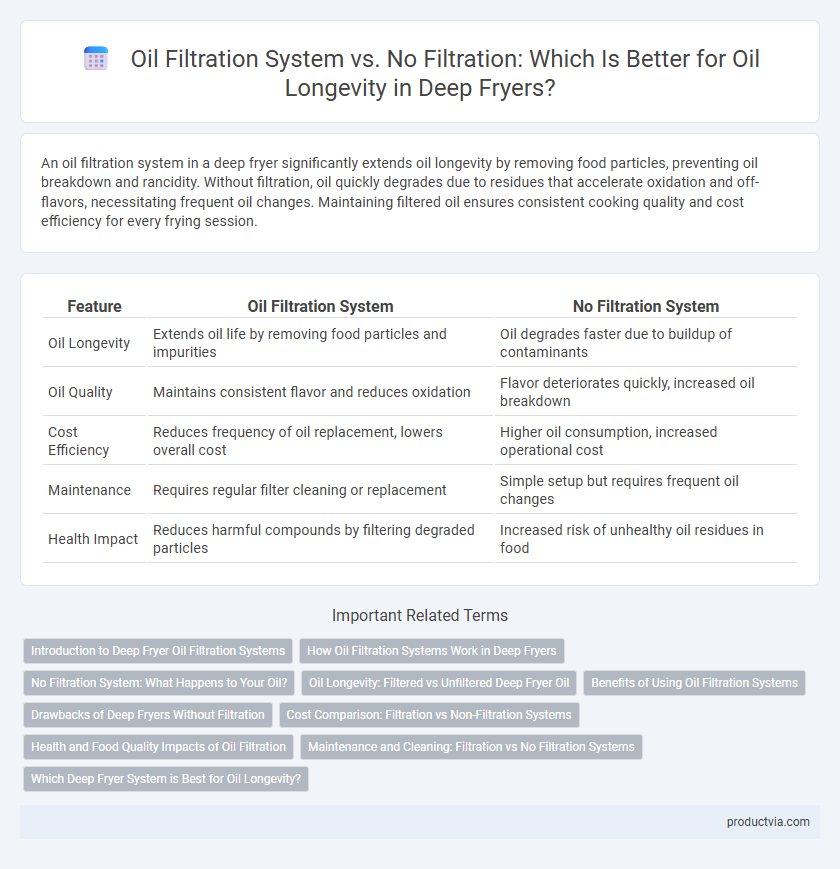

An oil filtration system in a deep fryer significantly extends oil longevity by removing food particles, preventing oil breakdown and rancidity. Without filtration, oil quickly degrades due to residues that accelerate oxidation and off-flavors, necessitating frequent oil changes. Maintaining filtered oil ensures consistent cooking quality and cost efficiency for every frying session.

Table of Comparison

| Feature | Oil Filtration System | No Filtration System |

|---|---|---|

| Oil Longevity | Extends oil life by removing food particles and impurities | Oil degrades faster due to buildup of contaminants |

| Oil Quality | Maintains consistent flavor and reduces oxidation | Flavor deteriorates quickly, increased oil breakdown |

| Cost Efficiency | Reduces frequency of oil replacement, lowers overall cost | Higher oil consumption, increased operational cost |

| Maintenance | Requires regular filter cleaning or replacement | Simple setup but requires frequent oil changes |

| Health Impact | Reduces harmful compounds by filtering degraded particles | Increased risk of unhealthy oil residues in food |

Introduction to Deep Fryer Oil Filtration Systems

Deep fryer oil filtration systems play a crucial role in extending oil longevity by removing food particles, impurities, and contaminants that degrade oil quality during frying. These systems maintain oil clarity and reduce the breakdown of frying oil, resulting in improved flavor retention, consistent cooking performance, and cost savings by reducing the frequency of oil changes. Without filtration systems, oil rapidly accumulates residues that lead to faster oxidation, increased acrid odors, and diminished frying efficiency.

How Oil Filtration Systems Work in Deep Fryers

Oil filtration systems in deep fryers work by continuously or periodically filtering out food particles, carbon residues, and contaminants from the hot oil, which helps maintain oil clarity and quality. These systems use fine mesh screens, paper filters, or centrifugal separators to trap debris, preventing oxidation and breakdown of the oil. Without filtration, oil deteriorates faster, leading to increased oil consumption, poorer food taste, and more frequent oil changes.

No Filtration System: What Happens to Your Oil?

Without an oil filtration system, deep fryer oil deteriorates rapidly due to the accumulation of food particles, carbonized debris, and moisture. This degradation leads to a reduced smoke point, off-flavors, and increased free fatty acids, compromising food quality and safety. Frequent oil changes become necessary, increasing operational costs and environmental waste.

Oil Longevity: Filtered vs Unfiltered Deep Fryer Oil

Filtered deep fryer oil retains its quality significantly longer than unfiltered oil by removing food particles and impurities that accelerate oxidation and breakdown. Utilizing an oil filtration system can extend oil life by up to 50%, reducing the frequency of oil changes and lowering operational costs. In contrast, unfiltered oil degrades rapidly, leading to poor frying performance and increased waste due to faster rancidity and contamination buildup.

Benefits of Using Oil Filtration Systems

Oil filtration systems significantly extend the longevity of cooking oil by removing food particles, impurities, and carbon residues that degrade oil quality. This process maintains oil clarity, reduces off-flavors, and preserves frying performance, resulting in cost savings and consistent food taste. Using an oil filtration system minimizes oil waste and enhances the overall efficiency of deep frying operations.

Drawbacks of Deep Fryers Without Filtration

Deep fryers without an oil filtration system suffer from rapid oil degradation due to the accumulation of food particles and burnt residues, which accelerate oxidation and decrease oil quality. This leads to a shorter lifespan of the frying oil, increased consumption costs, and a higher risk of off-flavors and harmful compounds in fried foods. Lack of filtration also results in more frequent oil changes, increased downtime, and potential equipment damage caused by sludge buildup.

Cost Comparison: Filtration vs Non-Filtration Systems

Oil filtration systems extend oil longevity by removing food particles and contaminants, reducing the frequency of oil replacement and lowering operational costs. Non-filtration systems require more frequent oil changes, increasing expenses due to higher oil consumption and disposal fees. The initial investment in a filtration system can be offset by long-term savings in oil costs, making it a cost-effective choice for commercial deep fryer operations.

Health and Food Quality Impacts of Oil Filtration

An oil filtration system in deep fryers significantly extends oil longevity by removing food particles and impurities that accelerate oil degradation, thereby maintaining healthier frying conditions. This filtration process reduces the formation of harmful compounds such as acrylamide and polar compounds, improving food safety and preserving flavor integrity. In contrast, no filtration leads to rapid oil deterioration, increased toxin accumulation, and compromised food quality with off-flavors and poor texture.

Maintenance and Cleaning: Filtration vs No Filtration Systems

Oil filtration systems in deep fryers significantly reduce the frequency of oil changes by continuously removing food particles and impurities, extending the oil's usable life and improving overall oil quality. Maintenance of filtration systems involves regular cleaning or replacement of filters, which prevents clogging and ensures consistent oil flow, while also reducing residue buildup on fryer components. No filtration systems require more frequent oil changes and intensive cleaning of the fryer to prevent accumulation of burnt particles, leading to higher operational costs and increased downtime for equipment maintenance.

Which Deep Fryer System is Best for Oil Longevity?

A deep fryer with an oil filtration system significantly extends oil longevity by removing food particles, reducing oil breakdown, and maintaining oil quality, which ultimately lowers operational costs. In contrast, deep fryers without filtration systems accumulate debris faster, leading to quicker oil degradation and frequent oil replacement. For businesses prioritizing oil longevity and cost efficiency, deep fryers equipped with built-in or external oil filtration systems are the best choice.

Oil filtration system vs No filtration system for oil longevity Infographic

productvia.com

productvia.com