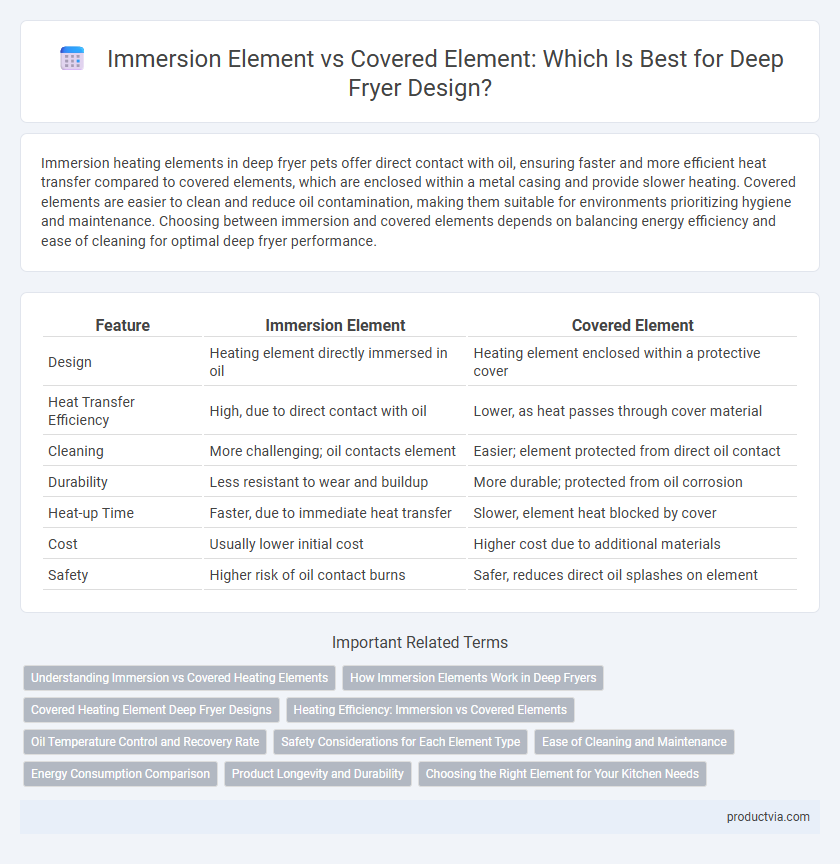

Immersion heating elements in deep fryer pets offer direct contact with oil, ensuring faster and more efficient heat transfer compared to covered elements, which are enclosed within a metal casing and provide slower heating. Covered elements are easier to clean and reduce oil contamination, making them suitable for environments prioritizing hygiene and maintenance. Choosing between immersion and covered elements depends on balancing energy efficiency and ease of cleaning for optimal deep fryer performance.

Table of Comparison

| Feature | Immersion Element | Covered Element |

|---|---|---|

| Design | Heating element directly immersed in oil | Heating element enclosed within a protective cover |

| Heat Transfer Efficiency | High, due to direct contact with oil | Lower, as heat passes through cover material |

| Cleaning | More challenging; oil contacts element | Easier; element protected from direct oil contact |

| Durability | Less resistant to wear and buildup | More durable; protected from oil corrosion |

| Heat-up Time | Faster, due to immediate heat transfer | Slower, element heat blocked by cover |

| Cost | Usually lower initial cost | Higher cost due to additional materials |

| Safety | Higher risk of oil contact burns | Safer, reduces direct oil splashes on element |

Understanding Immersion vs Covered Heating Elements

Immersion heating elements in deep fryers are submerged directly in the oil, ensuring rapid and even heat transfer for consistent frying temperatures. Covered heating elements, although enclosed in a protective sheath, offer reduced oil exposure to contaminants and easier cleaning but may exhibit slower heat response times. Selecting between immersion and covered elements impacts the efficiency, maintenance, and durability of the deep fryer design.

How Immersion Elements Work in Deep Fryers

Immersion elements in deep fryers function by directly submerging heating coils into the oil, enabling rapid and efficient heat transfer for consistent frying temperatures. This design ensures quicker heat-up times and uniform cooking, reducing energy consumption compared to covered heating elements that rely on indirect heat conduction. Immersion elements also facilitate easier cleaning and maintenance, enhancing fryer performance and longevity.

Covered Heating Element Deep Fryer Designs

Covered heating element deep fryer designs offer enhanced safety by preventing direct contact between oil and the heating element, reducing the risk of oil degradation and element damage. These designs facilitate easier cleaning and maintenance since food particles and oil residue remain less likely to accumulate on the element surface. Commercial kitchens benefit from covered elements because they provide consistent heat distribution while prolonging the lifespan of the fryer components.

Heating Efficiency: Immersion vs Covered Elements

Immersion heating elements in deep fryers provide superior heating efficiency by directly contacting the oil, resulting in faster heat transfer and more consistent temperature control. Covered elements, while easier to clean and less prone to burning oil debris, have slower heat conduction due to the protective coating, which can lead to uneven heating. Choosing immersion elements enhances energy efficiency and reduces cooking time, making them ideal for high-performance deep fryers.

Oil Temperature Control and Recovery Rate

Immersion heating elements in deep fryers provide more efficient oil temperature control by being directly submerged, enabling rapid heat transfer and quicker temperature recovery after food is added. Covered elements, while easier to clean and less prone to oil degradation, typically result in slower heat recovery rates due to indirect heating. Optimizing element design directly impacts the fryer's ability to maintain consistent cooking temperatures, crucial for achieving uniform frying quality and preventing oil breakdown.

Safety Considerations for Each Element Type

Immersion heating elements in deep fryers pose a higher risk of electrical hazards due to direct contact with hot oil, necessitating rigorous insulation and waterproofing to prevent short circuits and shocks. Covered or tubular elements, encased in metal tubing, offer enhanced safety by isolating electrical components from oil exposure, reducing the likelihood of accidental electrical contact and oil contamination. Proper maintenance and regular inspection of both element types are critical to ensure safe operation and minimize fire hazards associated with overheating or oil buildup.

Ease of Cleaning and Maintenance

Immersion elements in deep fryers are fully submerged in oil, allowing for easier cleaning since they can be removed and soaked separately, reducing oil residue buildup. Covered elements are protected by a casing which prevents direct contact with oil but often trap grease and food particles underneath, making maintenance more labor-intensive. Choosing immersion elements typically results in more straightforward cleaning processes and faster maintenance cycles, enhancing overall fryer hygiene and efficiency.

Energy Consumption Comparison

Immersion element deep fryers exhibit higher energy efficiency by directly heating the oil, reducing heat loss and speeding up the oil temperature recovery compared to covered element designs, which have lower thermal conductivity due to their protective casing. Covered elements often require longer preheating times and consume more electricity to maintain consistent frying temperatures, leading to increased operational costs. Energy consumption data indicates immersion element fryers can save up to 15-25% on power usage during continuous frying operations relative to covered element counterparts.

Product Longevity and Durability

Immersion heating elements in deep fryers provide more efficient heat transfer and reduced risk of residue buildup, which enhances product longevity by minimizing corrosion and wear. Covered elements, while offering a safer surface and easier cleaning, may trap oil and debris underneath, potentially accelerating deterioration over time. Choosing immersion elements typically results in improved durability and extended operational life for commercial deep fryer designs.

Choosing the Right Element for Your Kitchen Needs

Immersion heating elements in deep fryers offer faster heating and easier cleaning due to their direct contact with oil, making them ideal for commercial kitchens requiring efficiency. Covered elements provide a protective shield that prevents oil from splattering and extends element lifespan, suitable for home use or smaller cooking volumes. Selecting between immersion and covered elements depends on kitchen demands for speed, maintenance, and durability in frying operations.

Immersion element vs Covered element for deep fryer design Infographic

productvia.com

productvia.com