Ceramic coating on an electric skillet provides a non-stick surface free from PTFE and PFOA, making it a safer, eco-friendly option that resists high temperatures and metal utensil damage. Teflon coating offers excellent non-stick properties and easy food release but may degrade when exposed to high heat or scratched by metal tools, potentially releasing harmful chemicals. Choosing between ceramic and Teflon coatings depends on prioritizing durability, safety, and maintenance for your electric skillet cooking needs.

Table of Comparison

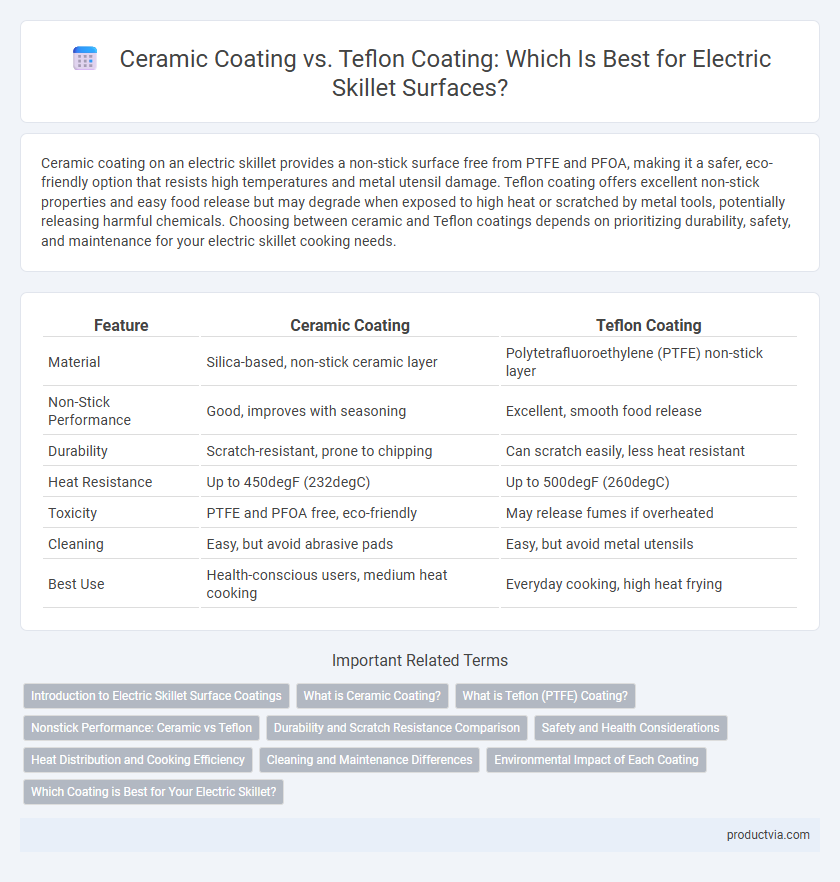

| Feature | Ceramic Coating | Teflon Coating |

|---|---|---|

| Material | Silica-based, non-stick ceramic layer | Polytetrafluoroethylene (PTFE) non-stick layer |

| Non-Stick Performance | Good, improves with seasoning | Excellent, smooth food release |

| Durability | Scratch-resistant, prone to chipping | Can scratch easily, less heat resistant |

| Heat Resistance | Up to 450degF (232degC) | Up to 500degF (260degC) |

| Toxicity | PTFE and PFOA free, eco-friendly | May release fumes if overheated |

| Cleaning | Easy, but avoid abrasive pads | Easy, but avoid metal utensils |

| Best Use | Health-conscious users, medium heat cooking | Everyday cooking, high heat frying |

Introduction to Electric Skillet Surface Coatings

Ceramic coating and Teflon coating are the two primary surface treatments used in electric skillets to enhance non-stick properties and durability. Ceramic coatings offer a natural, chemical-free non-stick surface that resists high temperatures and scratching, making it suitable for healthier cooking with minimal oil. Teflon coatings, made from polytetrafluoroethylene (PTFE), provide excellent stick resistance and easy cleanup but require careful handling to avoid overheating and surface damage.

What is Ceramic Coating?

Ceramic coating in electric skillets refers to a non-stick surface made from inorganic minerals, typically silica-based, that offers a durable, scratch-resistant, and toxin-free cooking area. Unlike Teflon, which is a synthetic polymer known as polytetrafluoroethylene (PTFE), ceramic coatings provide a naturally slick yet sturdy surface that withstands higher temperatures without releasing harmful fumes. This coating promotes healthier cooking by requiring less oil and is favored for its eco-friendly manufacturing process and long-lasting non-stick performance.

What is Teflon (PTFE) Coating?

Teflon coating, also known as PTFE (polytetrafluoroethylene), is a synthetic polymer used on electric skillet surfaces to provide a non-stick cooking experience. This coating offers excellent resistance to high temperatures and minimizes food sticking, reducing the need for excessive oil or butter. However, Teflon can degrade over time if scratched or exposed to temperatures above 500degF (260degC), potentially releasing harmful fumes.

Nonstick Performance: Ceramic vs Teflon

Ceramic coating provides a naturally nonstick surface that resists scratching and withstands higher cooking temperatures better than Teflon, which can degrade and release harmful fumes if overheated. Teflon coating offers superior initial nonstick performance with less need for oils or fats, enhancing low-fat cooking efficiency. However, ceramic coatings often last longer and maintain nonstick properties without chemical deterioration, making them a durable option for electric skillet surfaces.

Durability and Scratch Resistance Comparison

Ceramic coating on electric skillet surfaces offers superior durability and enhanced scratch resistance compared to traditional Teflon coating, making it less prone to chipping and wear over time. Teflon coatings, while providing excellent non-stick properties, tend to degrade faster with frequent use and are more susceptible to scratches from metal utensils. Choosing ceramic-coated electric skillets ensures longer-lasting performance and reduced risk of coating damage during regular cooking activities.

Safety and Health Considerations

Ceramic coatings on electric skillets offer a non-toxic, chemical-free surface that resists scratches and avoids the release of harmful fumes at high temperatures, making them a safer option for health-conscious users. Teflon coatings, while providing excellent non-stick properties, may emit toxic fumes when overheated above 500degF, posing potential respiratory risks. Choosing ceramic-coated skillets reduces exposure to perfluorooctanoic acid (PFOA) and polytetrafluoroethylene (PTFE), chemicals commonly associated with traditional Teflon surfaces and linked to long-term health concerns.

Heat Distribution and Cooking Efficiency

Ceramic coating on electric skillet surfaces offers superior heat distribution due to its ability to maintain consistent temperatures, resulting in more even cooking and reduced hot spots. Teflon coating, while effective for non-stick purposes, can have uneven heat conduction that may affect cooking efficiency and lead to inconsistent results. Ceramic coatings also tend to retain heat longer, improving energy efficiency and overall cooking performance.

Cleaning and Maintenance Differences

Ceramic-coated electric skillets offer a non-stick surface that is highly resistant to scratches and easy to clean with mild detergents and soft sponges, requiring no harsh chemicals. Teflon-coated skillets, while also non-stick, demand gentler handling to avoid scratching the delicate polytetrafluoroethylene (PTFE) layer and may require specialized cleaners to maintain performance. Over time, ceramic coatings tend to retain their non-stick properties longer under rigorous cleaning, whereas Teflon coatings may degrade faster if exposed to abrasive scrubbing or high heat.

Environmental Impact of Each Coating

Ceramic coatings for electric skillets are typically derived from natural materials such as sand and oxygen, making them non-toxic and environmentally friendly due to their biodegradability and lack of harmful chemical emissions during production and use. Teflon coatings, made from polytetrafluoroethylene (PTFE), pose environmental concerns both in manufacturing--where perfluorooctanoic acid (PFOA) was historically used as a processing aid--and at end-of-life disposal, as they are non-biodegradable and can release toxic fumes when overheated. Choosing ceramic-coated electric skillets reduces ecological footprint by minimizing hazardous waste and promoting safer indoor air quality.

Which Coating is Best for Your Electric Skillet?

Ceramic coating offers a non-toxic, eco-friendly surface that withstands higher temperatures without releasing harmful fumes, making it ideal for health-conscious users. Teflon coating provides superior non-stick performance and easier food release but can degrade at high heat, requiring more delicate handling. Choosing between ceramic and Teflon depends on whether you prioritize durability and chemical-free cooking or ease of cleaning and maximum non-stick properties.

Ceramic Coating vs Teflon Coating for Electric Skillet Surface Infographic

productvia.com

productvia.com